Antistatic organic silicon transparent hard coating layer material and preparation method thereof

A hard coating, silicone technology, applied in conductive coatings, coatings and other directions, can solve the problems of antistatic performance decline with time and humidity, antistatic performance retention time is short, antistatic performance decline, etc., to achieve excellent antistatic performance. Excellent electrostatic properties, excellent scratch resistance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

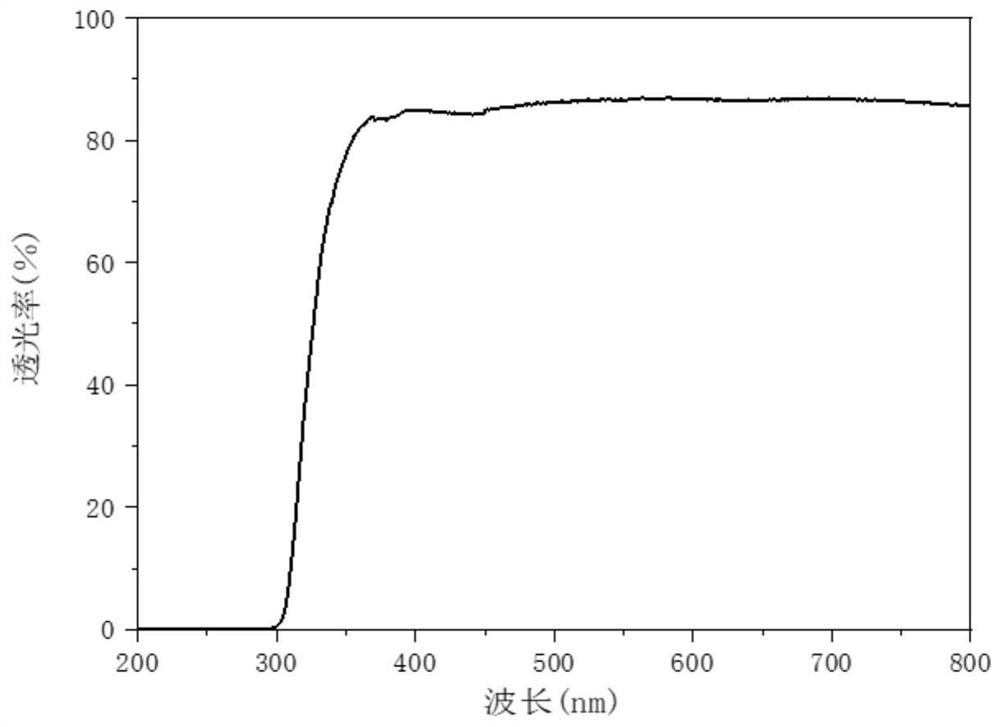

[0025] Methyl orthosilicate, methyltrimethoxysilane, dimethyldimethoxysilane, γ-(2,3-glycidoxy)-propyltrimethoxysilane and N,N-dimethyl -N-octadecylaminopropyltrimethoxysilane quaternary ammonium salt was stirred evenly in methanol, added 0.1% formic acid by mass fraction, reacted at 30°C for 4h; added 0.1% by mass fraction of cobalt acetylacetonate, and obtained Layer material solution; spray the above material solution on the surface of the plastic substrate, and after the surface is dry, cure at 80°C for 0.5h to obtain an antistatic silicone transparent hard coating. The hardness of the coating is 9H, the adhesion is 5B, the light transmittance is 88%, and the surface resistance value is 2.9×10 9 Ω. (Such as figure 1 shown)

Embodiment 2

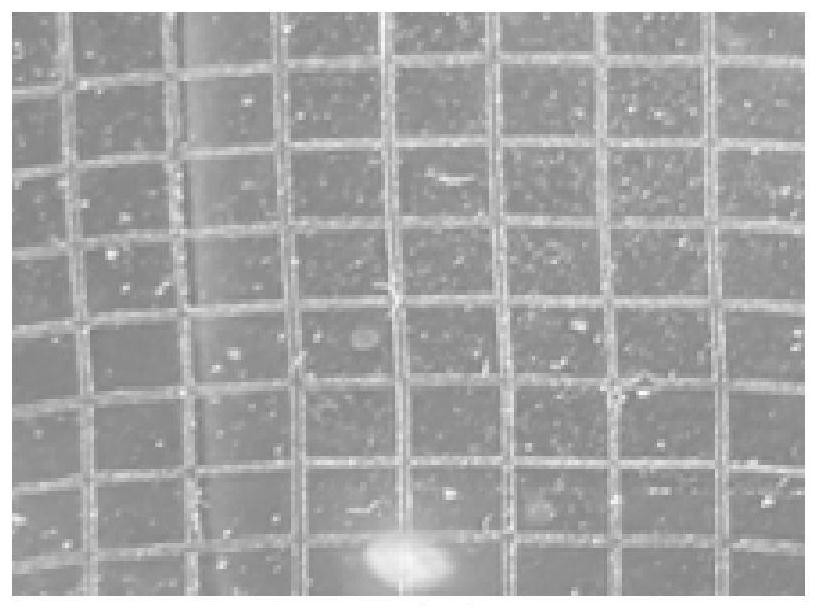

[0027] Methyl orthosilicate, methyltriethoxysilane, diethyldimethoxysilane, γ-(2,3-glycidoxy)propylmethyldiethoxysilane and N,N- Dimethyl-N-dodecylaminopropyl trimethoxysilyl ammonium chloride was stirred evenly in butyl acetate, added nitric acid with a mass fraction of 0.3%, and reacted at 50°C for 5 hours; manganese acetone to obtain a coating material solution; spray the above material solution on the surface of the plastic substrate, and after the surface is dry, cure at 120°C for 0.8h to obtain an antistatic silicone transparent hard coating. The hardness of the coating is 9H, the adhesion is 5B, the light transmittance is 90%, and the surface resistance value is 3.0×10 9 Ω. (Such as figure 2 shown)

Embodiment 3

[0029] Ethyl orthosilicate, ethyltrimethoxysilane, dimethyldiethoxysilane, 2-(3,4-epoxycyclohexylethyl)trimethoxysilane and N,N-dimethyl- Stir N-dodecylaminopropyltrimethoxysilyl ammonium chloride in n-butanol evenly, add hydrochloric acid with a mass fraction of 1%, and react at 40°C for 7 hours; add aluminum acetylacetonate with a mass fraction of 0.5%, to obtain Coating material liquid: Spray the above material liquid on the surface of the plastic substrate, and after the surface is dry, cure at 110°C for 0.9h to obtain an antistatic silicone transparent hard coating. The hardness of the coating is 9H, the adhesion is 5B, the light transmittance is 89%, and the surface resistance value is 2.9×10 9 Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com