High-flux mordenite molecular sieve membrane as well as preparation method and application thereof

A mordenite and molecular sieve technology, which is applied in the field of high-flux mordenite molecular sieve membrane and its preparation, can solve the problems of low permeation flux, poor acid resistance, poor membrane reproduction, etc. of the sieve membrane, and achieves simple synthesis device and broad application prospects. , the preparation method is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Seed coating:

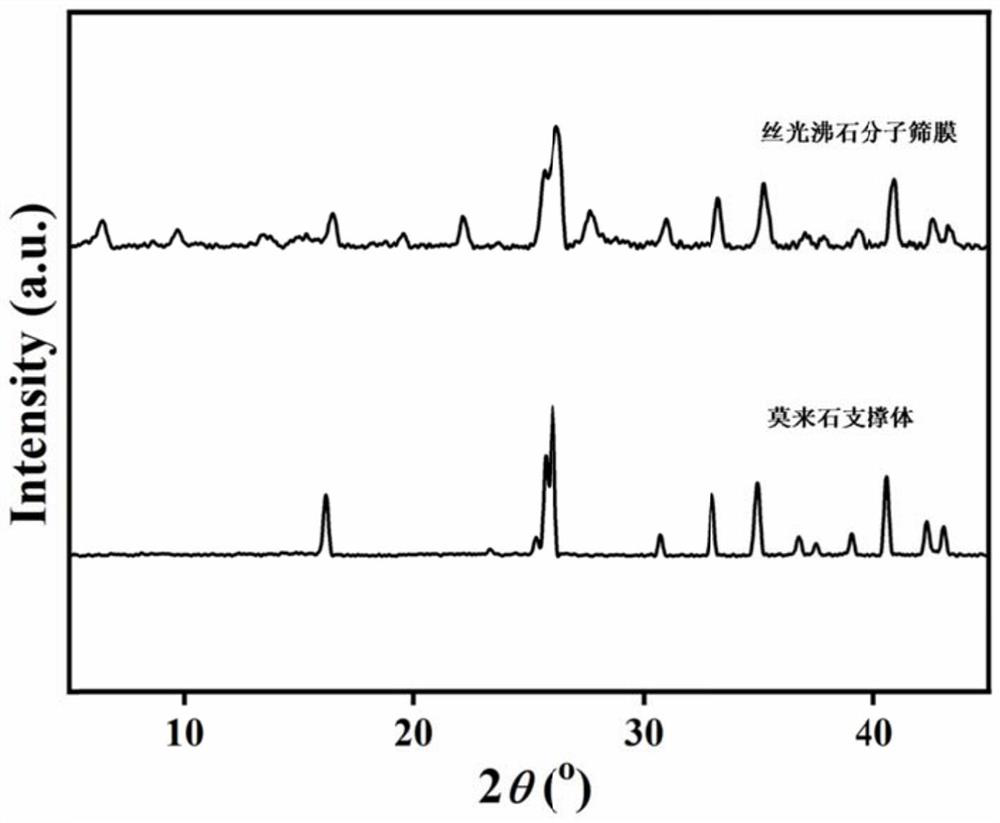

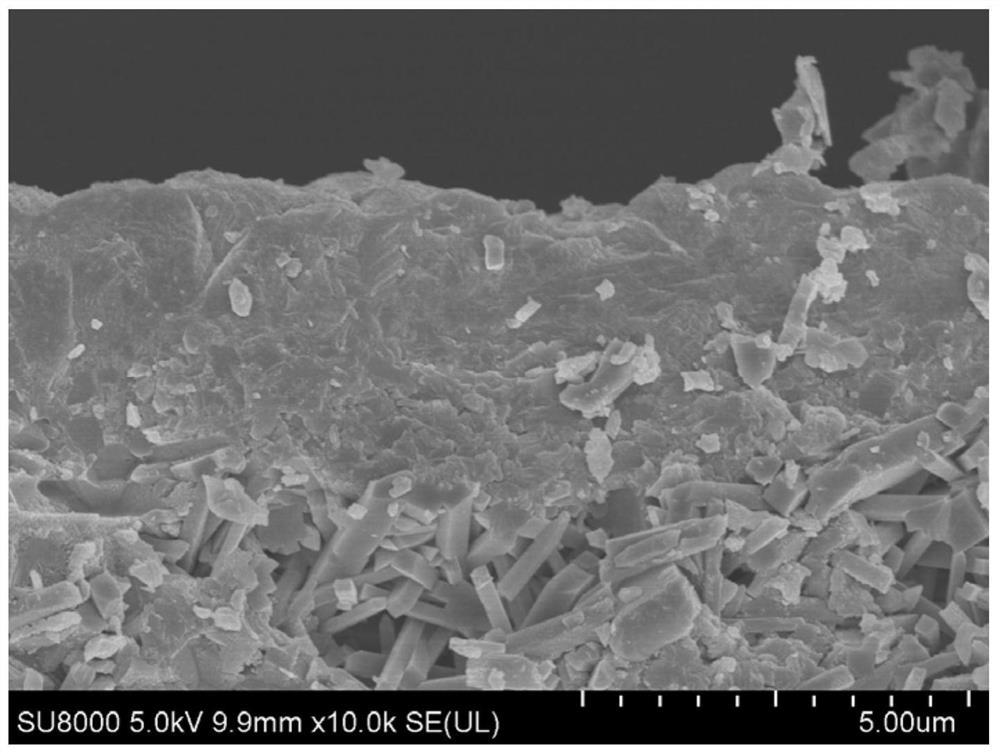

[0035] The support used in this experiment is the tubular mullite produced by Nikkato Co., Ltd. in Japan as the carrier for the synthesis of mordenite molecular sieve membranes. The inner and outer diameters of the carrier are 9mm and 12mm respectively, the length is 100mm, and the porosity is about 43%. , with an average pore size of about 1.3 μm. After alkali heat treatment, the carrier was smoothed with 1200-mesh sandpaper, washed with 80°C deionized water for 30 minutes, cleaned in an ultrasonic cleaner, and dried for later use.

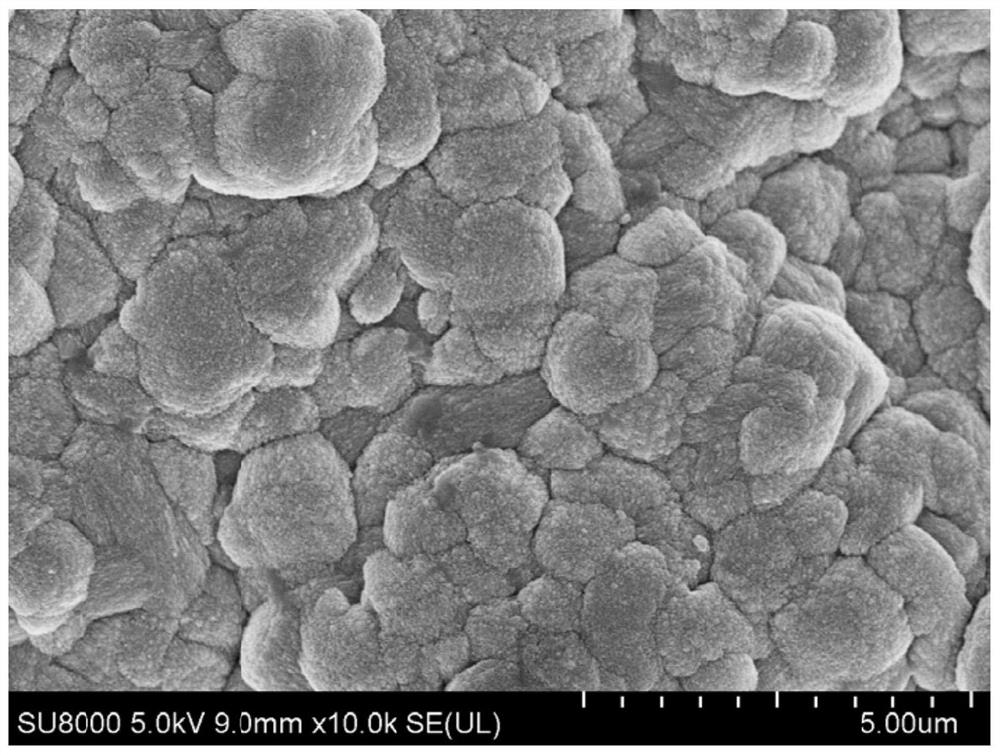

[0036] Both ends of the mullite carrier were sealed with polytetrafluoroethylene plugs to force the seed crystals to be introduced only to the outer surface of the carrier. The sealed carrier tube was preheated in an oven at 100°C, and then the hot carrier was quickly put into a mordenite molecular sieve seed solution with a concentration of 0.5 wt%, and slowly removed after 40 seconds. Take out the polytetrafluoroethy...

Embodiment 2

[0046] The synthetic sol raw materials, proportions and operation steps used are the same as in Example 1, only the synthesis temperature is raised to 185° C., and the crystallization time is adjusted to 4 hours.

[0047] The synthetic molecular sieve membrane is used for pervaporation experiment and characterization, tests its pervaporation performance (90 ℃) in the acetic acid / water (90 / 10wt%) system, and experimental result sees WM-03 in table 2 (as Figure 4 ) and WM-04.

[0048] Table 2

[0049]

Embodiment 3

[0051] The operation that adopts is as embodiment 2, uses potassium hydroxide as alkali source in the synthetic raw material, and potassium fluoride is fluorine source, and other raw materials are with embodiment 2.

[0052] The synthesized molecular sieve membrane was used in the pervaporation experiment to test its pervaporation performance (90°C) in the acetic acid / water (90 / 10wt%) system. The experimental results are shown in WM-05 and WM-06 in the table.

[0053] table 3

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com