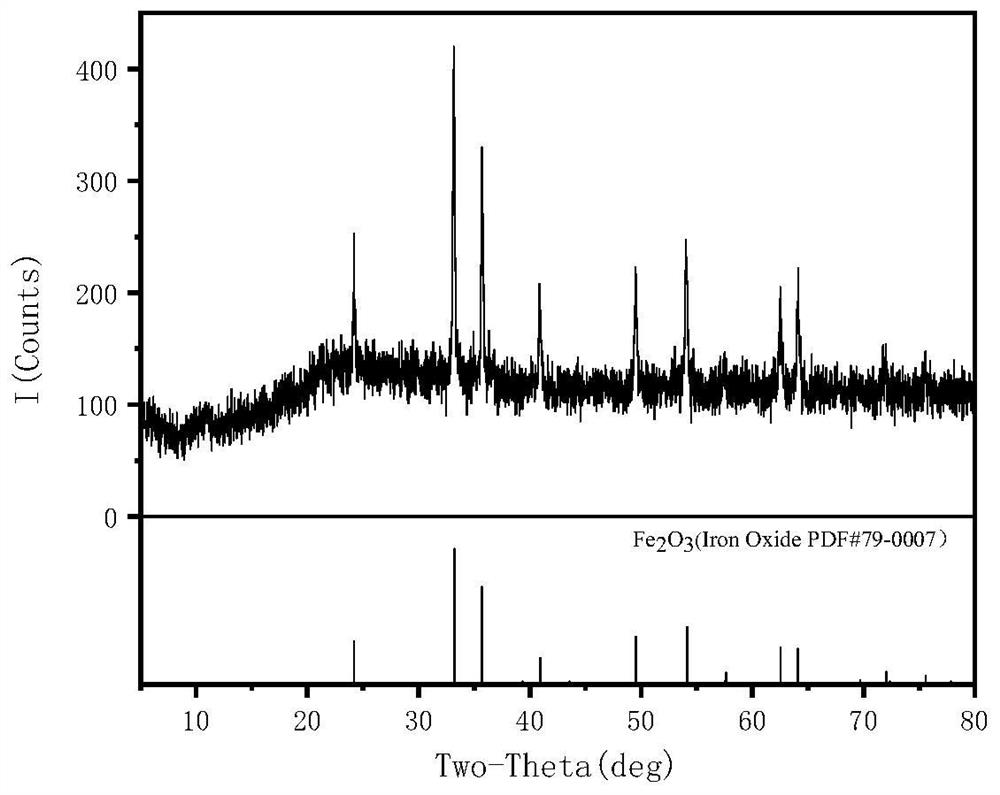

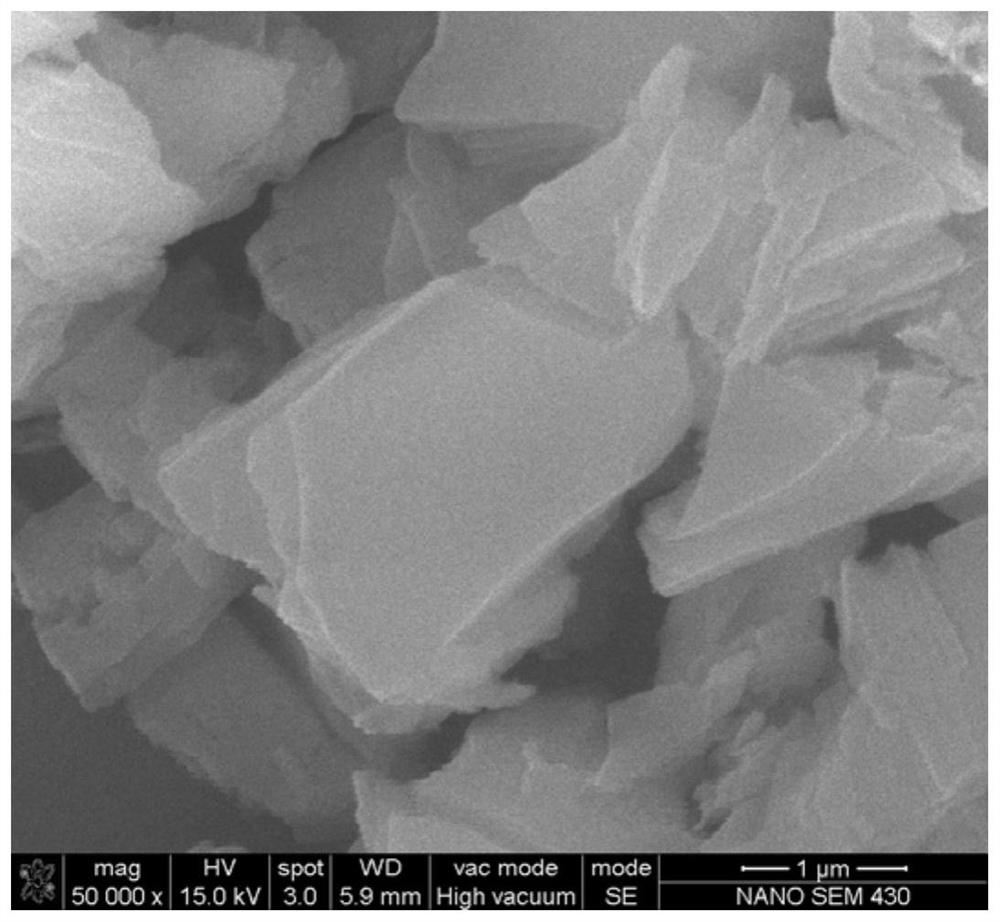

Method for synchronously preparing iron oxide red and sodium disilicate by utilizing desiliconized sludge

A technology of sodium disilicate and red iron oxide, applied in the directions of iron oxide, iron oxide/iron hydroxide, silicate, etc., can solve the problem of difficult separation of sodium disilicate, and achieve good effect and low residual chlorine content , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method of synchronously preparing iron oxide red and sodium disilicate by utilizing desiliconization sludge in this embodiment, the steps are:

[0037] 1. Take the desiliconized sludge from the iron and steel plant, extrude it into a spherical shape, put it into a muffle furnace for roasting, the roasting temperature is 600 ° C, and the holding time is 2 hours. Finally, the desiliconized sludge after calcining and dechlorination is ground, and the particle size of the grinding requires a 0.08mm square hole sieve with a residue of 5.2%.

[0038] 2. SiO in the desiliconized sludge after grinding 2 Mass content 25.48%, get 100g and put into autoclave, and add 40% sodium hydroxide solution 40.5ml wherein, mol ratio is n(Na 2 O):n(SiO 2 ) = 1:2.1, then add water to a solid-to-liquid ratio of 1:3, and conduct a hydrothermal reaction at 200°C in a high-pressure reactor for a reaction time of 60 minutes, so that the silicon dioxide in the iron oxide powder and the lye are f...

Embodiment 2

[0044] A method of synchronously preparing iron oxide red and sodium disilicate by utilizing desiliconization sludge in this embodiment, the steps are:

[0045] 1. Take the desiliconized sludge from the iron and steel plant, extrude it into a spherical shape, put it into a muffle furnace for roasting, the roasting temperature is 650°C, and the holding time is 1.5h. Finally, the desiliconized sludge after calcining and dechlorination is ground, and the particle size of the grinding requires a 0.08mm square hole sieve with a residue of 7.3%.

[0046] 2. SiO in the desiliconized sludge after grinding 2 Mass content 27.72%, get 75g and put into autoclave, and add 30% sodium hydroxide solution 45.1ml wherein, mol ratio is n(Na 2 O):n(SiO 2 ) = 1:2.05, and then add water to a solid-liquid ratio of 1:10. The high-pressure reactor is subjected to a hydrothermal reaction at 180°C for a reaction time of 100 minutes, so that the silicon dioxide in the iron oxide powder and the lye are ...

Embodiment 3

[0052] A method of synchronously preparing iron oxide red and sodium disilicate by utilizing desiliconization sludge in this embodiment, the steps are:

[0053] 1. Take the desiliconization sludge from the iron and steel plant, extrude it into a rod shape, put it into a muffle furnace for roasting, the roasting temperature is 700°C, and the holding time is 1h. Finally, the desiliconized sludge after calcining and dechlorination is ground, and the particle size of the grinding requires a 0.08mm square hole sieve with a residue of 4.9%.

[0054] 2. The desiliconized sludge after grinding, in which SiO 2 Mass content 26.13%, get 100g and put into autoclave, and add 20% sodium hydroxide solution 87.1ml wherein, mol ratio is n(Na 2 O):n(SiO 2 ) = 1:2, and then add water to a solid-liquid ratio of 1:5. The high-pressure reactor is subjected to a hydrothermal reaction at 170°C, and the reaction time is 100 minutes, so that the silicon dioxide in the iron oxide powder and the lye ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com