Method for preventing lignin degradation intermediate product polycondensation

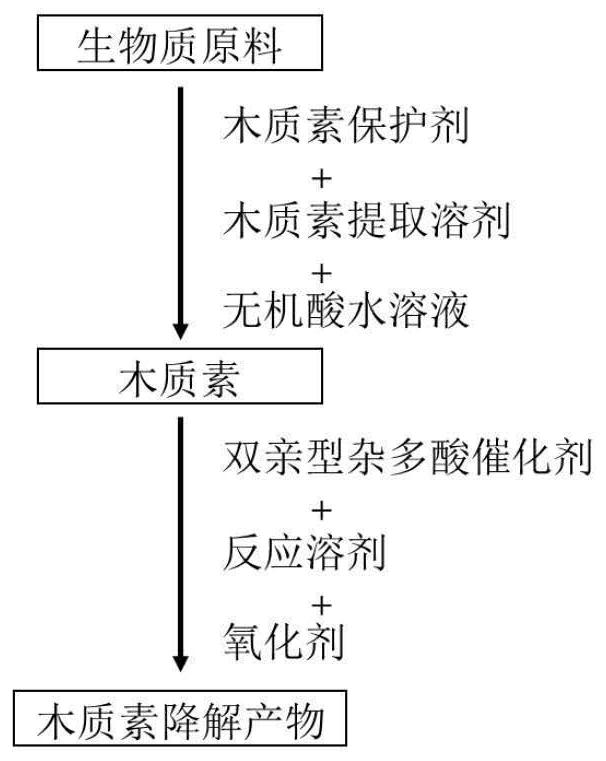

A lignin and product technology, applied in the field of biomass catalytic conversion, can solve the problems of easy polycondensation and refractory oligomers, low yield of lignin monomer, and low yield of target products, so as to avoid polycondensation reaction and benefit High value utilization and effect of reducing polycondensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

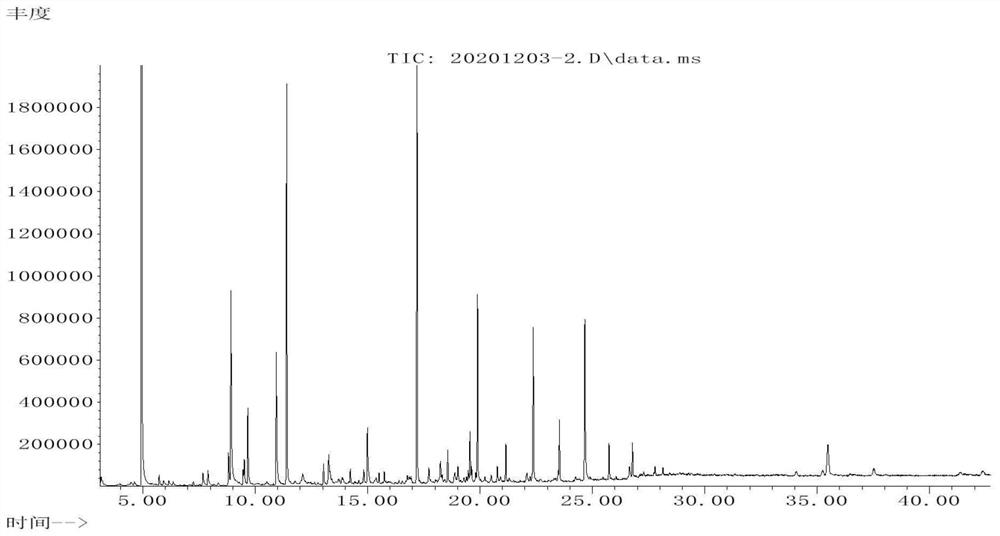

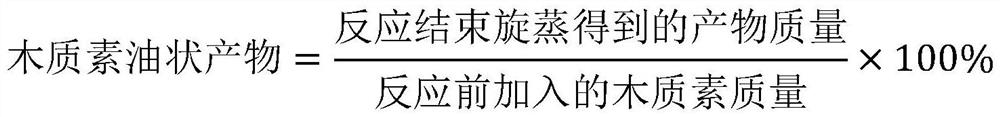

Examples

Embodiment 1

[0040]Preparation of formaldehyde-pretreated lignin: Add 10g of birch wood powder, 90mL of 1,4-dioxane, 4.2mL of 0.15mol / L hydrochloric acid, and 9.5mL of formaldehyde into a three-necked flask, and react at 80°C for 3h. Formaldehyde pretreated lignin was obtained by filtration, rotary steaming and centrifugation.

Embodiment 2

[0042] Preparation of acetaldehyde pretreated lignin: Add 10g of spruce wood powder, 90mL of dichloromethane, 4.2mL of 0.2mol / L sulfuric acid, and 9.5mL of acetaldehyde into a three-necked flask, and react at 70°C for 1 hour. After the reaction, filter, Rotary steaming and centrifugation to obtain acetaldehyde pretreated lignin.

Embodiment 3

[0044] Preparation of propionaldehyde pretreated lignin: add 10g corn stalk powder, 90mL equal volume mixed solution of tetrahydrofuran and ethanol, 4.2mL equal volume mixed solution of 0.25mol / L hydrochloric acid and nitric acid, 9.5mL propionaldehyde into a three-necked flask, 90°C The reaction was carried out for 2 hours, and after the reaction was completed, the propionaldehyde pretreated lignin was obtained by filtration, rotary evaporation, and centrifugation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com