Unsaturated fatty acid modified water-based acrylic resin dispersion body and preparation method thereof

A technology of unsaturated fatty acid and water-based acrylic acid, which is applied in the direction of coating, etc., and can solve problems such as limited application, water whitening phenomenon, and low hardness of resin coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

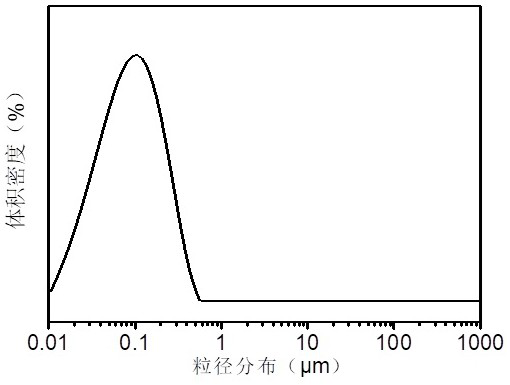

Embodiment 1

[0035] A kind of unsaturated fatty acid modified aqueous acrylic resin dispersion, by mass parts as follows:

[0036] Soybean oleic acid: 8 parts;

[0037] Glycidyl methacrylate: 8 parts;

[0038] Inhibitor: 4-methoxyphenol, 0.15 parts;

[0039] Catalyst: tetrabutylammonium bromide, 0.3 part;

[0040] Solvent: Ethylene glycol monobutyl ether, propylene glycol methyl ether, n-butanol: 21 parts, 10.5 parts, 11 parts respectively;

[0041] Chain transfer agent: mercaptoethanol, 0.2 part;

[0042] Hard monomers: styrene and methyl methacrylate, accounting for 22 and 12 parts respectively;

[0043] Soft monomer: butyl acrylate, 45 parts;

[0044] Acrylic carboxyl monomer: acrylic acid, 8 parts;

[0045] Initiator: azobisisobutyronitrile, 2 parts;

[0046] Neutralizer: N-N dimethylethanolamine, 5.5 parts;

[0047] Dispersant: deionized water, 150 parts.

[0048] The preparation process is:

[0049](1) Weigh the mixed solution of styrene, methyl methacrylate, butyl acrylate...

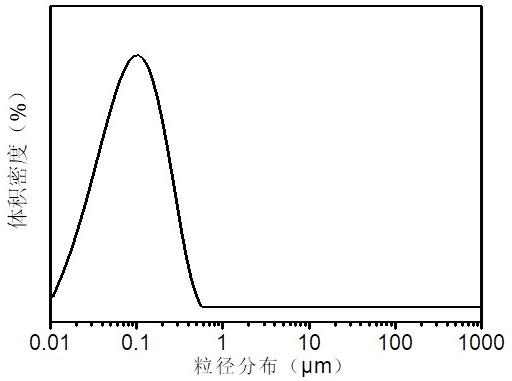

Embodiment 2

[0054] A kind of unsaturated fatty acid modified aqueous acrylic resin dispersion, by mass parts as follows:

[0055] Linoleic acid: 6 parts;

[0056] Glycidyl methacrylate: 5.4 parts;

[0057] Inhibitor: hydroquinone, 0.1 part;

[0058] Catalyst: tetrabutylammonium bromide, 0.15 parts;

[0059] Solvent: diethylene glycol butyl ether, n-butanol: respectively accounting for 20 parts and 16 parts;

[0060] Chain transfer agent: n-dodecyl mercaptan, 0.12 parts;

[0061] Hard monomers: styrene and methyl methacrylate, accounting for 16 and 14 parts respectively;

[0062] Soft monomer: butyl acrylate, 36 parts;

[0063] Acrylic carboxyl monomer: methacrylic acid, 6.5 parts;

[0064] Initiator: azobisisobutyronitrile, 1.6 parts;

[0065] Neutralizer: triethylamine, 4.2 parts;

[0066] Dispersant: deionized water, 120 parts.

[0067] The preparation process is:

[0068] (1) Weigh the mixed solution of styrene, methyl methacrylate, butyl acrylate, methacrylic acid and initia...

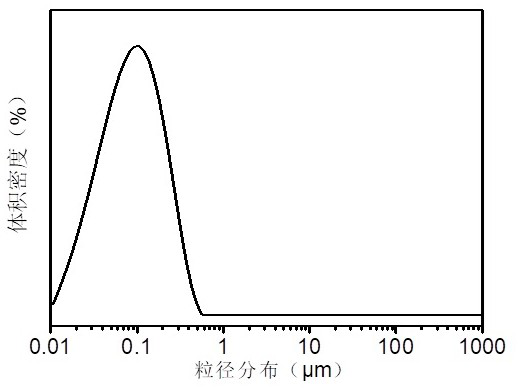

Embodiment 3

[0073] A kind of unsaturated fatty acid modified aqueous acrylic resin dispersion, by mass parts as follows:

[0074] Ricinoleic acid: 2 parts;

[0075] Glycidyl acrylate: 2 parts;

[0076] Inhibitor: 4-methoxyphenol, 0.05 part;

[0077] Catalyst: N-N dimethylethanolamine, 0.1 part;

[0078] Solvent: propylene glycol methyl ether, n-butanol: account for 12 parts and 8 parts respectively;

[0079] Chain transfer agent: mercaptoethanol, 0.1 part;

[0080] Hard monomers: styrene and methyl methacrylate, accounting for 12 and 8 parts respectively;

[0081] Soft monomer: n-octyl acrylate, 25 parts;

[0082] Acrylic carboxyl monomer: acrylic acid, 3 parts;

[0083] Initiator: dibenzoyl peroxide, 0.3 parts;

[0084] Neutralizer: N-N dimethylethanolamine, 2.5 parts;

[0085] Dispersant: deionized water, 70 parts.

[0086] The preparation process is:

[0087] (1) Weigh the mixed solution of styrene, methyl methacrylate, n-octyl acrylate, acrylic acid and initiator, wherein th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com