Antitumor photodynamic-sensitivity-enhanced-treatment photosensitizer/enzyme combined delivery system and preparation method therefor

A photodynamic and delivery system technology, applied in photodynamic therapy, biochemical equipment and methods, anti-tumor drugs, etc., can solve the problem of poor targeting, difficult to improve photosensitizer stability, nano-targeted delivery, difficult to achieve enzyme/ Issues such as targeted co-delivery of photosensitizers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Synthesis of boric acid-epoxy polymers

[0053] According to the molar ratio of diethylaminoethyl methacrylate to 4-bromomethylphenylboronic acid 1:0.5, a small amount of potassium iodide was added, dissolved in 6 mL N,N dimethylformamide, and reacted in the dark for 24 h. Under the condition of nitrogen protection, the prepared monomer, glycidyl methacrylate and N,N-methylenebisacrylamide were dissolved in 4 mL of N,N dimethyl formaldehyde according to the molar ratio of 1:1:0.5 amides. According to the molar ratio of boric acid-acrylic acid compound to the initiator azobisisobutyronitrile of 1:0.5, after vigorous reaction at 65°C for 12 h, the boric acid-epoxy polymer was obtained by extraction and purification with n-hexane, and rotary evaporation.

Embodiment 2

[0055] Synthesis of boric acid-epoxy polymers

[0056] According to the molar ratio of N-vinylpyrrolidone and 4-bromomethylphenylboronic acid 1:1, add a small amount of potassium iodide, dissolve in 6 mL N,N dimethylformamide, and react in the dark for 24 h. Under nitrogen protection, the prepared compound, glycidyl methacrylate and N,N-methylenebisacrylamide were dissolved in 4 mL N,N dimethylformamide at a molar ratio of 1:1:0.5 middle. According to the molar ratio of boric acid-acrylic acid compound and initiator azobisisobutyronitrile 1:0.5, after a vigorous reaction at 65°C for 12 h, the boric acid-epoxy polymer was obtained by extraction and purification with n-hexane, and rotary evaporation.

Embodiment 3

[0058] Synthesis of boric acid-epoxy polymers

[0059] According to the molar ratio of diethylaminoethyl methacrylate to 4-bromomethylphenylboronic acid of 1:2, add a small amount of potassium iodide, dissolve in 6 mL N,N dimethylformamide, and react in the dark for 24 h. Under the condition of nitrogen protection, the prepared compound, glycidyl acrylate and N,N-methylenebisacrylamide were dissolved in 4 mL N,N dimethylformamide according to the molar ratio of 1:1:0.5 . According to the molar ratio of boric acid-acrylic acid compound and initiator azobisisobutyronitrile 1:0.5, after a vigorous reaction at 65°C for 12 h, the boric acid-epoxy polymer was obtained by extraction and purification with n-hexane, and rotary evaporation.

PUM

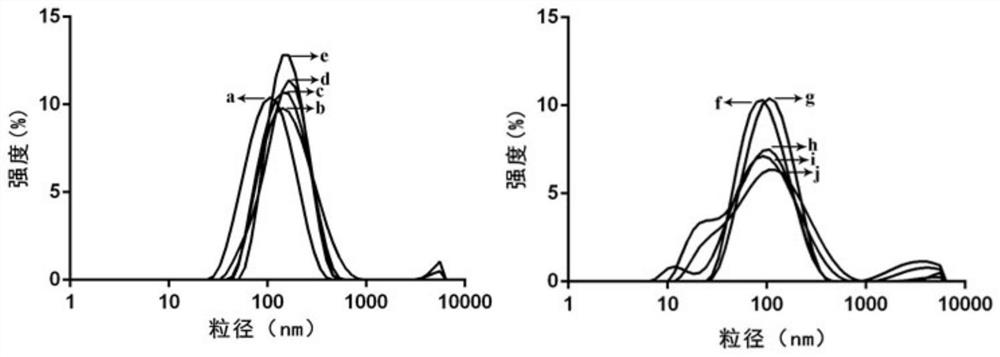

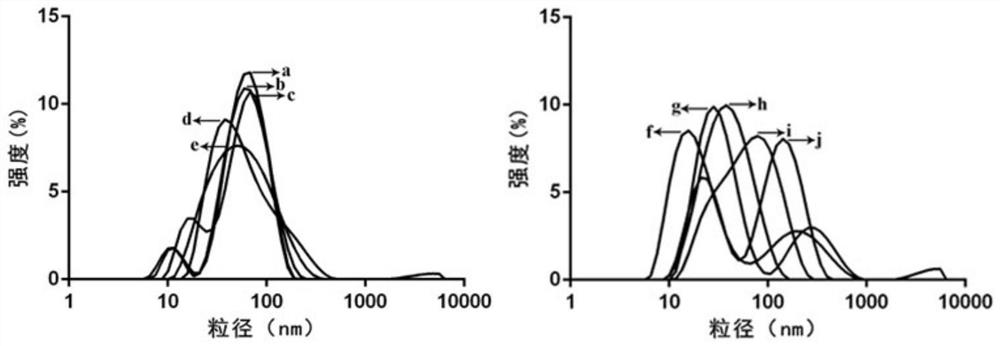

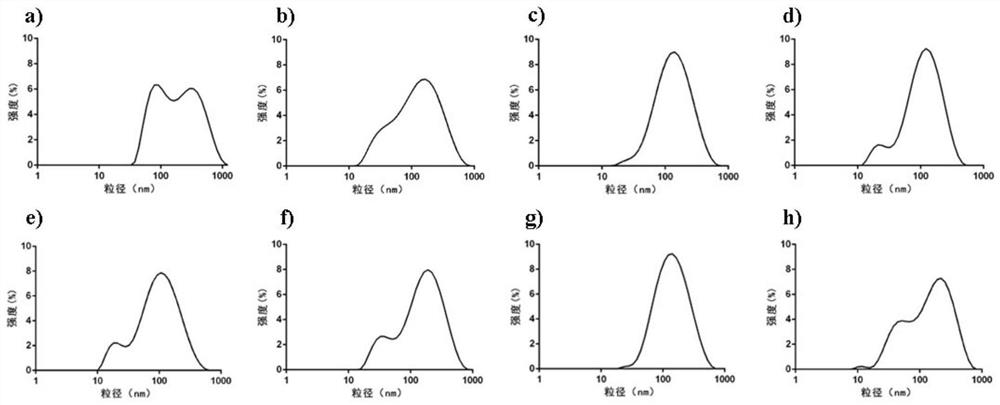

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com