Method for preparing iron phosphide/carbon composite material from yeast biomass

A technology of carbon composite materials and biomass, applied in chemical instruments and methods, oxidized water/sewage treatment, physical/chemical process catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

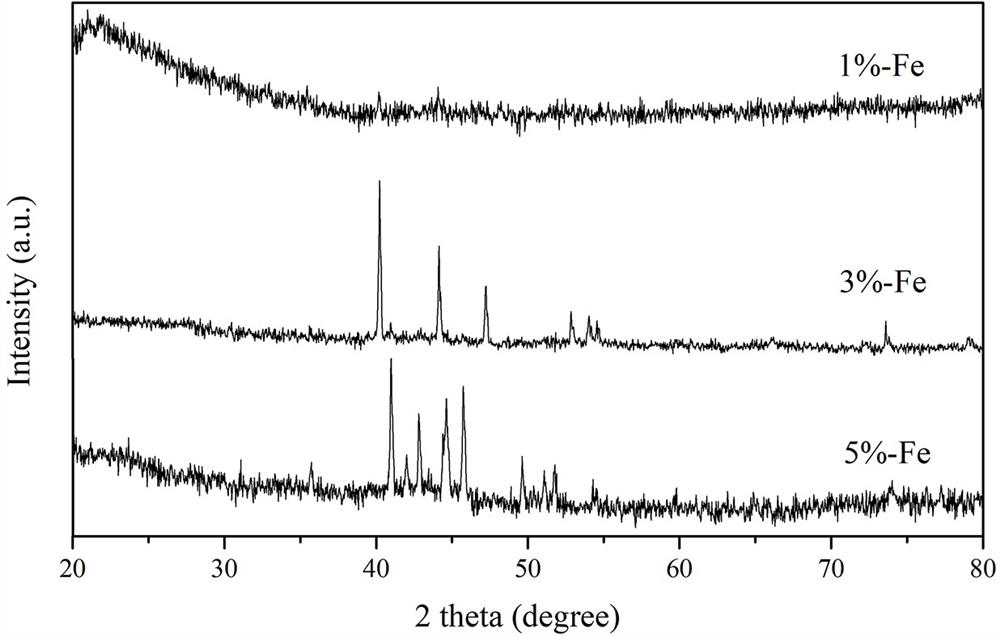

[0025] Disperse 50 g of baker's yeast cells evenly in 500 mL of ethanol, add 2.41 g of ferric chloride hexahydrate under magnetic stirring, then add a certain amount of ammonium bicarbonate and stir continuously for 6-12 h, centrifuge and wash the obtained complex Dry in a freeze dryer. The dried composite was transferred to a corundum crucible and placed in a tube furnace for calcination under a protective atmosphere at a temperature of 900 o C, the calcination time is 2-6 h, and the heating rate is 5 o C / min, take it out after cooling to room temperature. The resulting material was washed with deionized water in a vacuum oven for 60 o C drying to obtain iron phosphide / carbon material, named as 1%-Fe .

Embodiment 2

[0027] Disperse 50 g of baker's yeast cells evenly in 500 mL of ethanol, add 7.24 g of ferric chloride hexahydrate under magnetic stirring, then add a certain amount of ammonium bicarbonate and stir continuously for 6-12 h, centrifuge and wash the obtained complex Dry in a freeze dryer. The dried composite was transferred to a corundum crucible and placed in a tube furnace for calcination under a protective atmosphere at a temperature of 900 o C, the calcination time is 2-6 h, and the heating rate is 5 o C / min, take it out after cooling to room temperature. The resulting material was washed with deionized water in a vacuum oven for 60 o C drying to obtain iron phosphide / carbon material, named as 3%-Fe .

Embodiment 3

[0029] Disperse 50 g of baker's yeast cells evenly in 500 mL of ethanol, add 12.07 g of ferric chloride hexahydrate under magnetic stirring, and then add a certain amount of ammonium bicarbonate and stir continuously for 6-12 h, centrifuge and wash the obtained complex Dry in a freeze dryer. The dried composite was transferred to a corundum crucible and placed in a tube furnace for calcination under a protective atmosphere at a temperature of 900 o C, the calcination time is 2-6 h, and the heating rate is 5 o C / min, take it out after cooling to room temperature. The resulting material was washed with deionized water in a vacuum oven for 60 o C drying to obtain iron phosphide / carbon material, named as 5%-Fe .

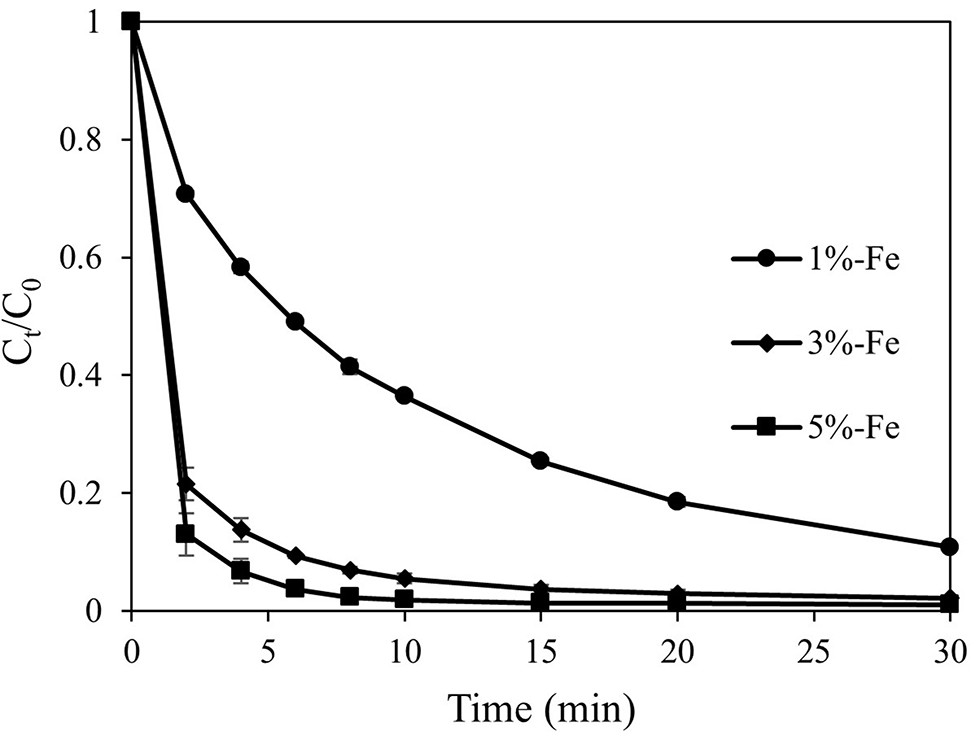

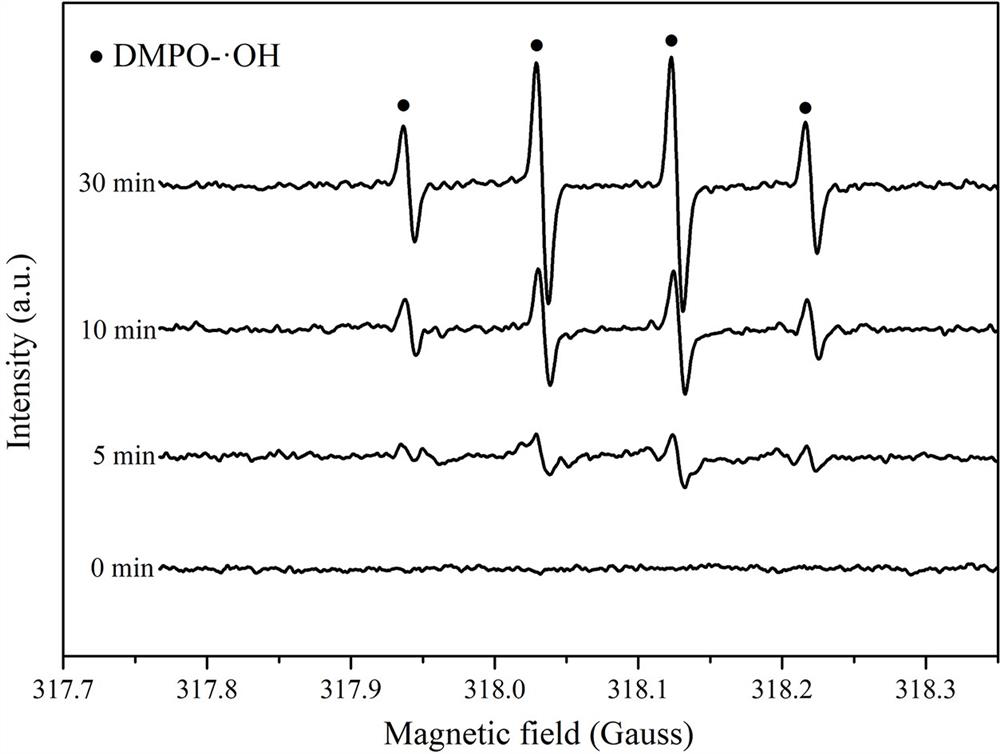

[0030] For investigating the catalytic degradation performance of iron phosphide / carbon material proposed by the present invention to sulfamethoxazole, the sulfamethoxazole solution of preparation 20mg / L is under the condition of 180 rpm at 30 ℃, shaker speed, with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com