A kind of lithium-sulfur battery composite positive electrode material and its preparation method and application

A composite positive electrode material, lithium-sulfur battery technology, applied in the direction of battery electrodes, lithium batteries, positive electrodes, etc., can solve the problems of poor conductivity of sulfur and discharge end products, low utilization of active materials, hindering industrial application, etc., to achieve inhibition Shuttle effect, ease of electrode volume change, effect of high load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment provides a method for preparing a lithium-sulfur battery composite positive electrode material, comprising the following steps:

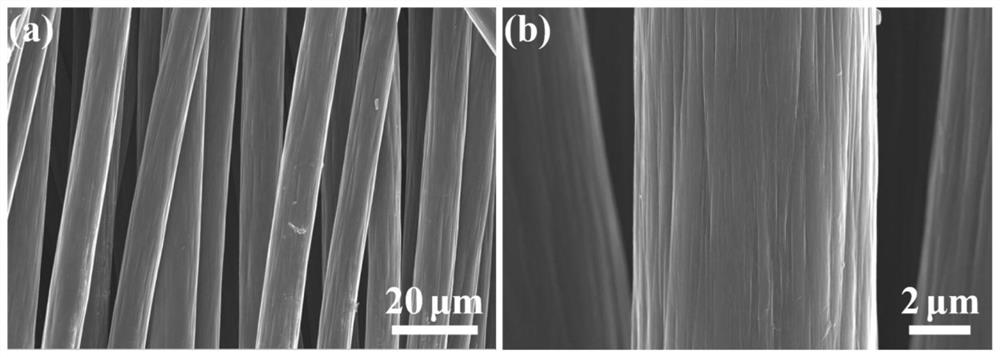

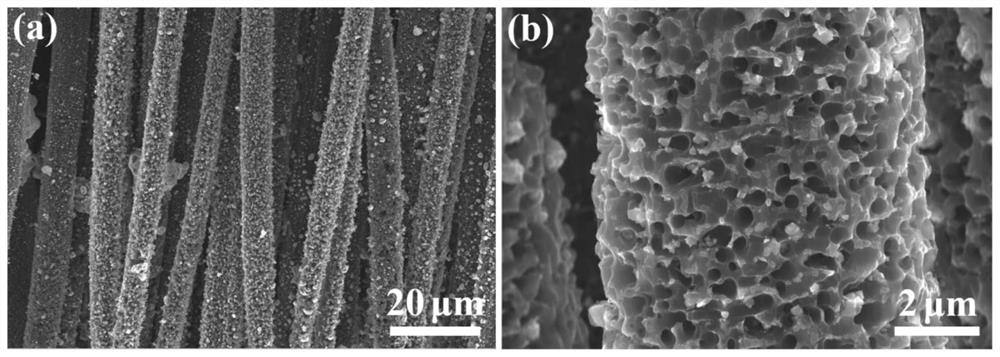

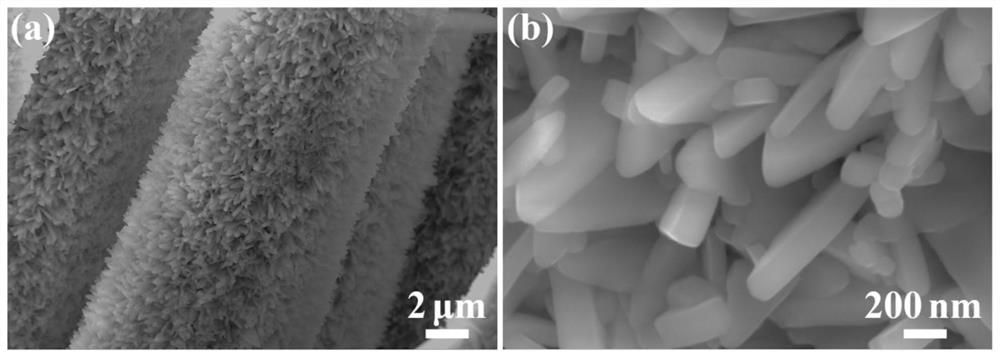

[0028] (1) Preparation of porous carbon fiber Ni / PCF with Ni nanoparticles embedded on the surface:

[0029] 1×1cm 2 Commercial carbon fibers were arranged in a mixed solution of concentrated nitric acid (68wt%) and concentrated sulfuric acid (98wt%) with a volume ratio of 1:3, refluxed at 80°C for 2h, then ultrasonically cleaned with acetone and absolute ethanol, and dried; configure 1M NaNO 3 and 1MNi(NO 3 ) 2 The mixed solution was used as the electrolyte, and Ni(OH) was deposited on the surface of carbon fiber (CF) by constant current electrodeposition. 2 , deposited at a current density of 6 mA cm -2 , the deposition time is 10min, and Ni(OH) 2 @CF Composite Materials; Finally Ni(OH) 2The @CF composite material was calcined at 800 °C for 5 h in an argon atmosphere to obtain porous carbon fiber Ni / PCF with Ni nanopar...

Embodiment 2

[0048] The preparation method of this example is the same as that of Example 1, except that the Ni / PCF prepared in step (1) is placed in 3M hydrochloric acid, pickled at 80°C for 6 hours to prepare PCF, and then the PCF is placed in hexahydrate The crystallization growth was carried out in the mixed solution of cobalt nitrate and 2-methylimidazole, and the conductive carrier Co / NC@PCF with no Ni particles on the surface of PCF but only Co / NC loaded on the surface of PCF was prepared, and other implementation conditions remained unchanged. Compared with Example 1, the capacity and cycle stability of the lithium-sulfur battery assembled with the positive electrode material prepared in this example are reduced, and the initial discharge capacity at 0.5C is 1073mAh g -1 , the discharge capacity after 300 cycles is 812mAh g -1 , the capacity retention rate is 75.7%; in addition, the rate performance is also reduced.

Embodiment 3

[0050] The preparation method of this embodiment is the same as that of Example 1, except that the calcination temperature in step (2) is 800° C., and other implementation conditions remain unchanged. Compared with Example 1, the capacity and cycle stability of the lithium-sulfur battery assembled with the positive electrode material prepared in this example remained basically unchanged, and the initial discharge capacity at 0.5C was 1092mAh g -1 , the discharge capacity after 300 cycles is 886mAhg -1 , the capacity retention rate was 81.1%; in addition, the rate performance remained basically unchanged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com