Low-temperature soldering paste added with anti-falling particles

An anti-drop and particle technology, which is applied in welding equipment, welding medium, metal processing equipment, etc., can solve the problem of low drop performance of solder joints, and achieve the effects of diverse acquisition methods, strong impact resistance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: The preparation method of low temperature solder paste without the addition of anti-drop particles is as follows:

[0033] 1, prepare flux:

[0034] The active agent (5% dika, DL-maline acid 3%, 2-ethylimidazole), film forming agent (PEG-2000 2%, acrylic modified rosin 18%, hydrogen smear 18%), touch The variable agent (4% hydrogenated castor oil), surfactant (PVP 1%), corrosion inhibitor (benzotriazole 1%) and solvent (40% of diethylene glycol Handhehered ether) mixed;

[0035] 2, 90% of the Sn-Bi alloy solder powder and the flux 10% in the step 1 are mixed, stirred for 0.5 h, resulting in an additional low temperature solder paste;

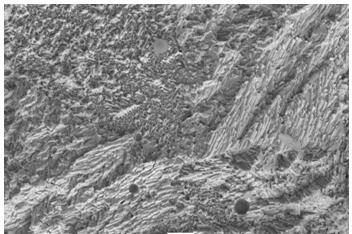

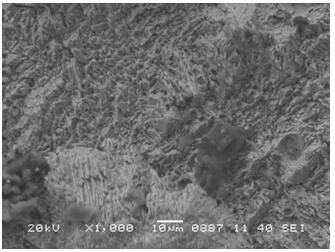

[0036] 3. Printing the solder paste in the surface of the pure copper pad, the pad size is 0.8mm, and reflow solder after the mounting components; the solder joint is from 75cm, freely fall, record the number of pads, as the pad diameter is 0.8 MM's reference sample, which falls behind the broken SEM map figure 1 See Table 1 for th...

Embodiment 2

[0037] Example 2: The preparation method of low temperature solder paste added to nylon 6 particles is as follows:

[0038] 1, prepare flux:

[0039] According to the mass ratio, the active agent (5% dika, 3%, 2-ethylimidazole), a film forming agent (PEG-20002%, acrylic-modified rosin 18%, 18% hydrogen fluid) , Thixotropic (4% hydrogenated castor oil), surfactant (PVP 1%), corrosion inhibitor (benzatonazole 1%), and solvent (diethylene glycol Handhethoid ether 40%) mixed uniform; According to 2%, 4%, 6% of the flux mass, nylon 6 particles having a particle diameter of 5 to 10 μm are added to the flux, respectively, and mixed mixing is mixed.

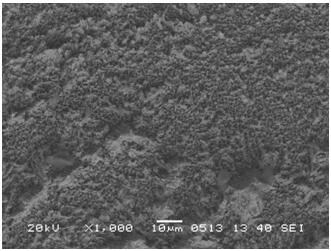

[0040] 2, 90% of the Sn-Bi alloy solder powder with the flux 10% in the step 1, stirred for 0.5 h, resulting in a low temperature solder paste added nylon 6 particles; nylon 6 particles SEM map Figure 5 ;

[0041] 3. Printing the solder paste in the surface of the pure copper pad, the pad size is 0.8mm, and reflow after the mounting componen...

Embodiment 3

[0042] Example 3: Preparation of low temperature solder paste without adding a reference contrast is as follows:

[0043] 1, prepare flux:

[0044] According to the mass ratio, the active agent (5% dika, 3%, 2-ethylimidazole), a film forming agent (PEG-20002%, acrylic-modified rosin 18%, 18% hydrogen fluid) , Thixotropic (4% of hydrogenated castor oil), surfactant (PVP 1%), corrosion inhibitor (benzatrazole 1%) and solvent (diethylene glycol Handhethhethoid ether 40%) mix well;

[0045] 2, 90% of the Sn-Bi alloy solder powder and the flux 10% in the step 1 are mixed, stirred for 0.5 h, resulting in an additional low temperature solder paste;

[0046] 3. Printing the solder paste in the surface of the pure copper pad, the pad size is 0.6mm, and reflow after the mounting components; the solder joint is from 75cm, freely fall, record the number of pads, as the pad diameter is 0.6 MM's reference, see Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com