Coal washing wastewater treatment agent as well as preparation method and application thereof

A technology for coal washing wastewater and treatment agent, applied in the field of coal chemical industry, can solve the problems of strong neurotoxicity and carcinogenicity, increase the content of iron and aluminum, hinder biological growth, etc. produced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

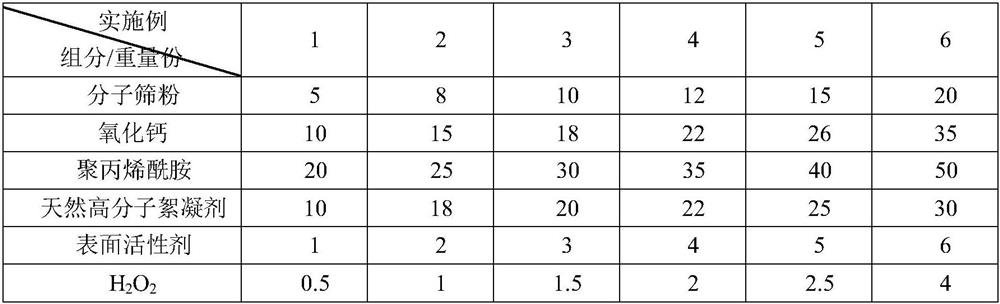

[0056] See Table 1 for the specific composition of the coal washing wastewater treatment agent of Examples 1-6.

[0057] Table 1

[0058]

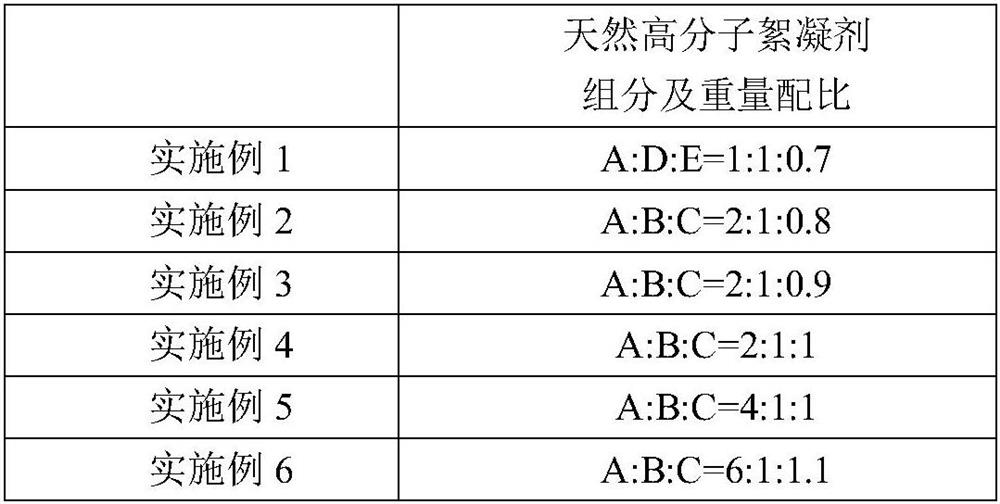

[0059] Wherein, the specific composition of the natural polymer flocculant in Examples 1-6 is shown in Table 2 below.

[0060] Table 2

[0061]

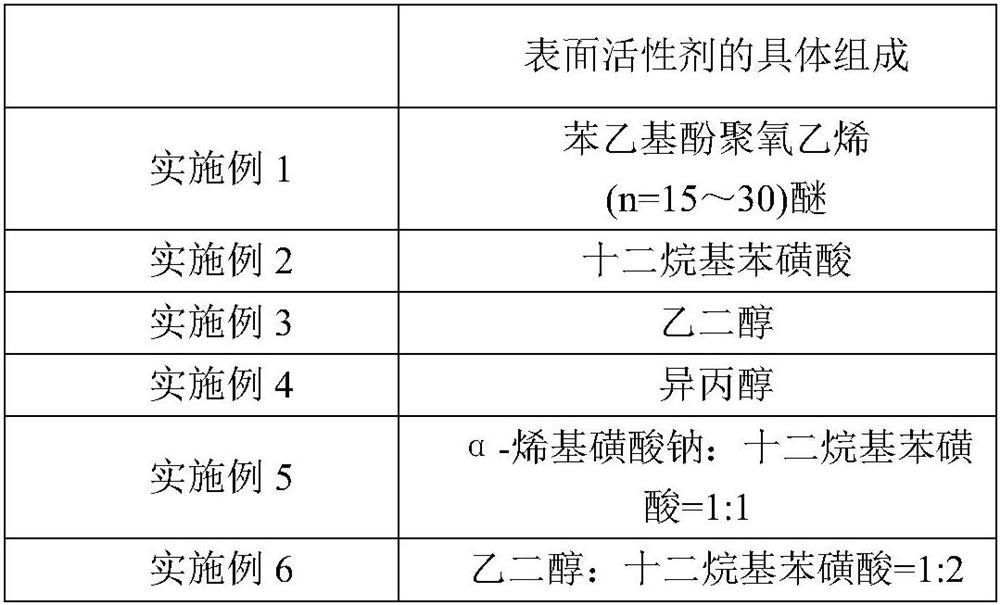

[0062] In Examples 1-6, the specific composition of the surfactant is shown in Table 3.

[0063] table 3

[0064]

[0065] In Examples 1-6, the specific types of molecular sieve powders are shown in Table 4.

[0066] Table 4

[0067] The specific composition of molecular sieve powder Example 1 X molecular sieve Example 2 Type A molecular sieve Example 3 ZSM molecular sieve Example 4 Mordenite: X-type molecular sieve = 1:1 Example 5 ZSM-5 / beta zeolite Example 6 ZSM-5 / beta zeolite / mordenite

[0068] The basic steps of the preparation method of embodiment 1-6 are as follows:

[0069] Prepare each component according to the formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com