Method for realizing positive and negative photoconduction in memristor by using optical signal

A photoconductive and optical signal technology, applied in electrical components and other directions, can solve problems such as no literature reports, and achieve the effects of simple and effective method, simple preparation, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

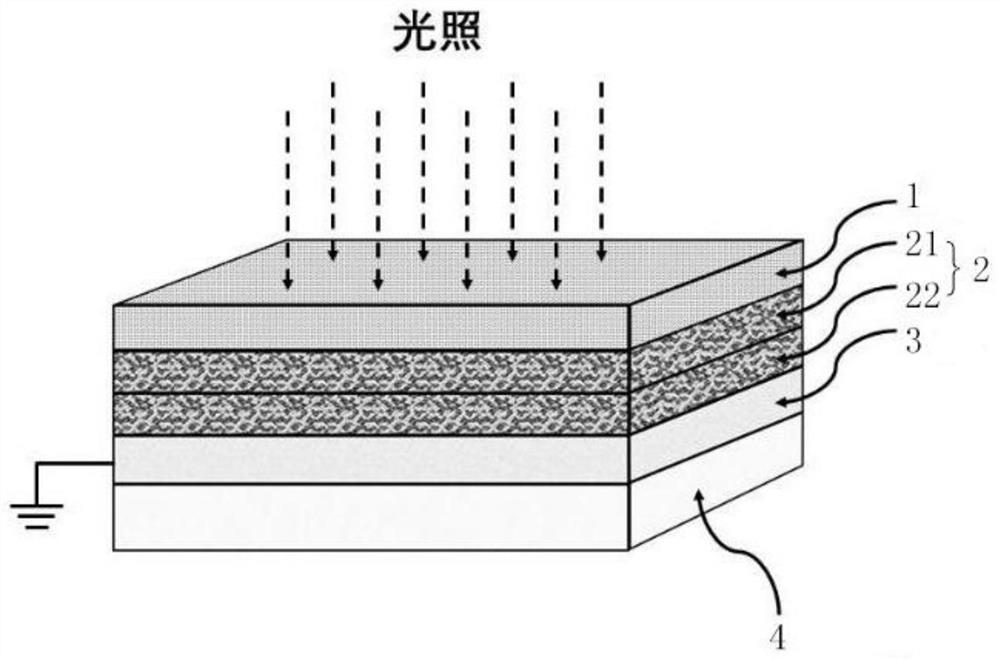

[0047] A memristor, comprising sequentially forming a bottom electrode layer 3 , an oxide layer 2 (an oxygen-deficient layer 22 and an oxygen-rich layer 21 ) and a top electrode layer 1 on a substrate 4 . The substrate in this embodiment is a thermally oxidized silicon wafer, the material of the bottom electrode layer 3 is platinum, and its thickness is 150 nm; the material of the oxide layer 2 is indium gallium zinc oxide (IGZO), which includes an oxygen-deficient layer and an oxygen-rich layer, and The thickness of the oxygen layer is 60nm, and the thickness of the oxygen-enriched layer is 20nm; the material of the top electrode layer is gold, and its thickness is 10nm.

[0048] The preparation method of the memristor of the present embodiment is as follows:

[0049] (1) A 6nm-thick titanium film was prepared on the surface of the substrate by electron beam evaporation as a buffer layer. The main function was to increase the mechanical bonding force between the platinum film...

Embodiment 2

[0060] The difference from Example 1 is that the bottom electrode layer is tin-doped indium oxide (ITO) grown by magnetron sputtering, with ITO as the sputtering target, with argon as the sputtering atmosphere, the substrate temperature is room temperature, and the sputtering The power is 20-100W, the temperature is 20-50°C, and the time is 1-120min. The thickness of the ITO film is 200nm, the IGZO film includes an oxygen-deficient layer and an oxygen-rich layer, the thickness of the oxygen-deficient layer is 60nm, the thickness of the oxygen-rich layer is 20nm, and the thickness of the gold electrode is 10nm.

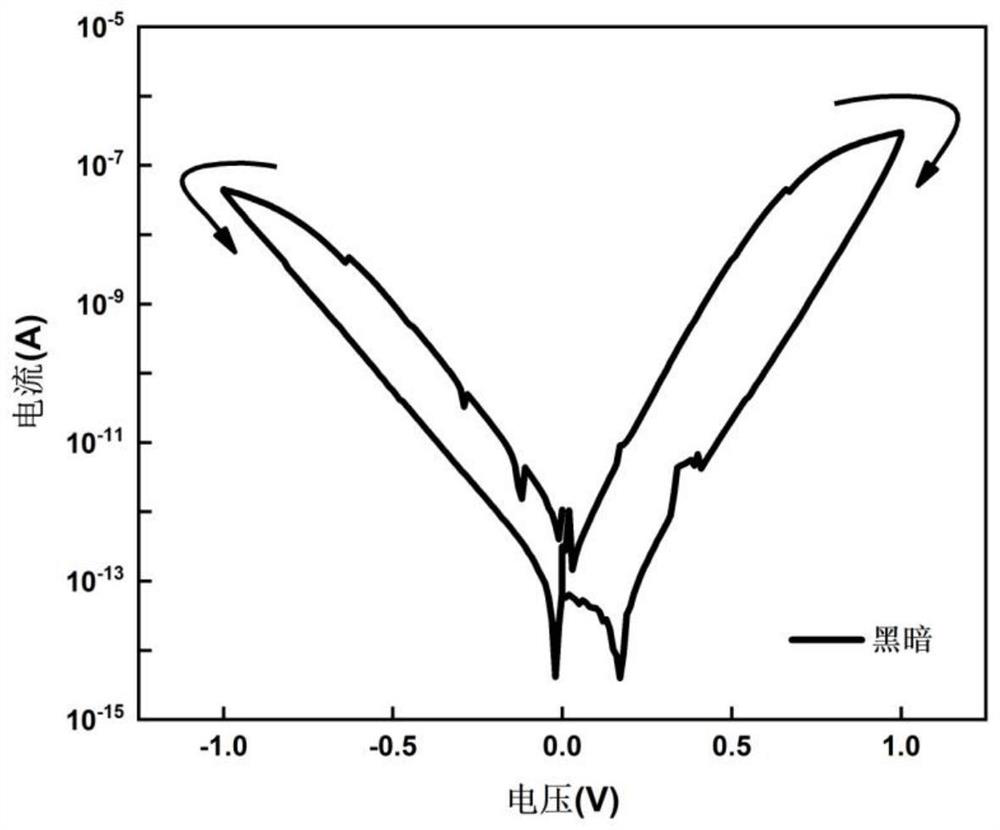

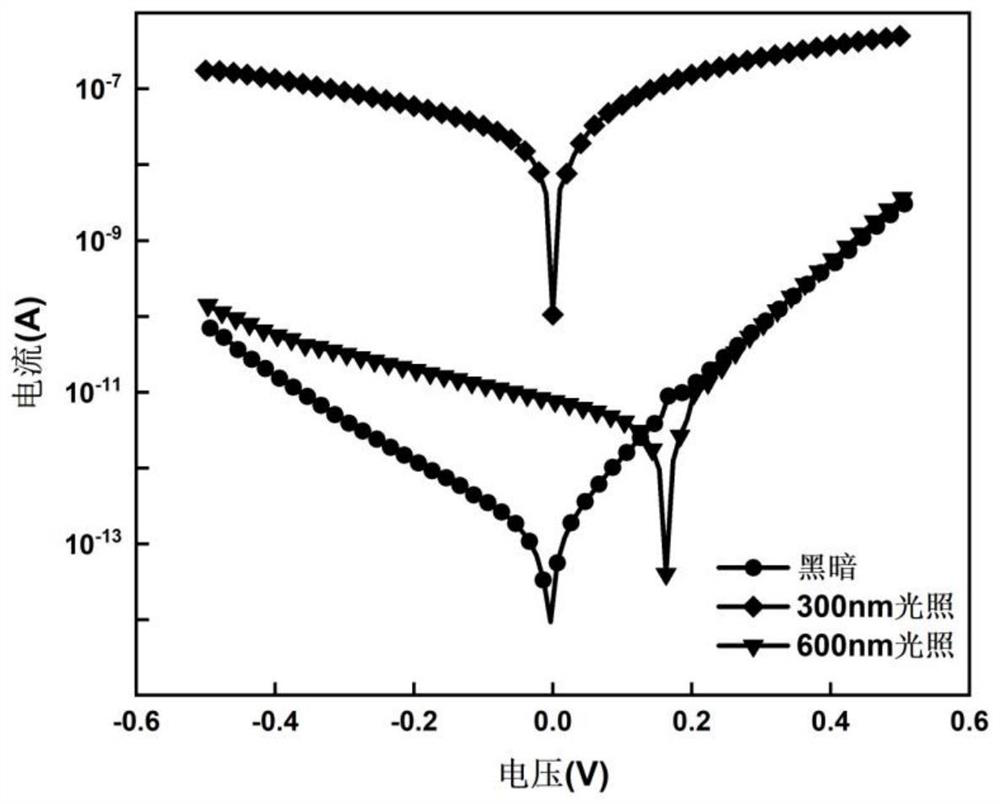

[0061] Figure 6 The current-voltage characteristic curve of the memristor prepared for this example in a dark environment, the bottom electrode is grounded, and the voltage is applied to the top electrode, and an obvious hysteresis window can be seen. Figure 7The current-voltage linear scanning curve of the memristor prepared for this example under a dark environmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com