Preparation method of green bismuth vanadate particles

A technology of green bismuth vanadate and particles is applied in the field of preparation of green bismuth vanadate particles, which can solve the problems of unstable BiVO4 of quantum dots and unfavorable complexes, and achieves improved visible light response performance, high preparation efficiency, and suppression of surface defects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The present embodiment provides a preparation method of green bismuth vanadate particles, comprising the following steps:

[0034] S11 Take Yellow BiVO 4 The particles are preheated at a certain temperature, the preheating temperature is 200-300 °C, to remove the yellow BiVO 4 Impurities on the particle surface. Preheating can be carried out in a muffle furnace, or in a tube furnace under the protection of inert gas to ensure the cleanliness of the sample.

[0035] Among them, the yellow BiVO 4 The particle size of the particles ranges from 5 nm to 1000 nm.

[0036] S12 will preheat the yellow BiVO 4 The particles are placed on a quartz glass substrate and pressed by covering the pressing glass;

[0037] S13 uses a laser to align the yellow BiVO covered with laminated glass that reaches a certain surface flatness (surface fluctuation error range is -0.1 ~ 0.1mm). 4 Irradiate for 5-15s. The color of the glass changes from transparent to non-transparent after laser...

Embodiment 2

[0041] A preparation method of green bismuth vanadate particles, the steps are as follows:

[0042] (1) The yellow monoclinic BiVO 4 The particles (particle size 200 nm) were preheated in a muffle furnace at 200° C. to clean their surfaces.

[0043] (2) The preprocessed BiVO 4 Pressing is performed on the quartz glass substrate by covering the pressing glass, and the surface fluctuation error range of the sample after pressing is guaranteed to be within -0.1 to 0.1 mm.

[0044] (3) BiVO covered with laminated glass by laser 4 The irradiation treatment was performed for 8s, and the parameters of the laser were selected as: wavelength 1064nm; power 1W; pulse frequency 1000Hz. The pulse width of the laser is 8 ns.

[0045] (4) BiVO after one irradiation in (3) 4 The particles were re-mixed uniformly, and steps (2) and (3) were repeated for a total of 6 times to obtain green uniform BiVO 4 particles.

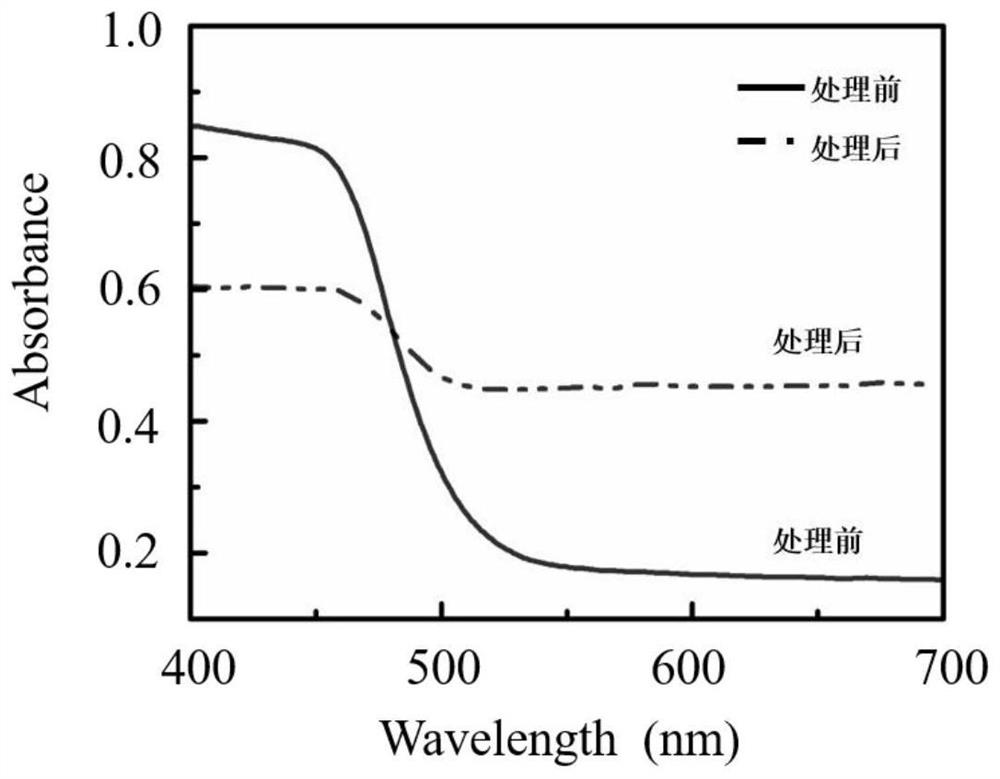

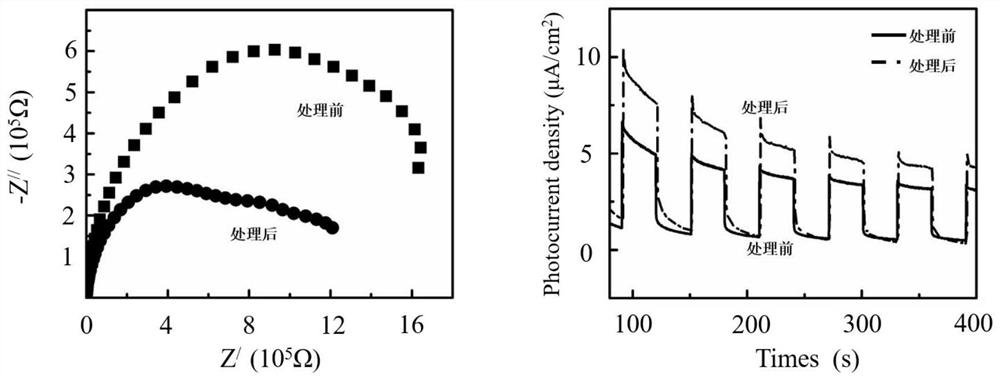

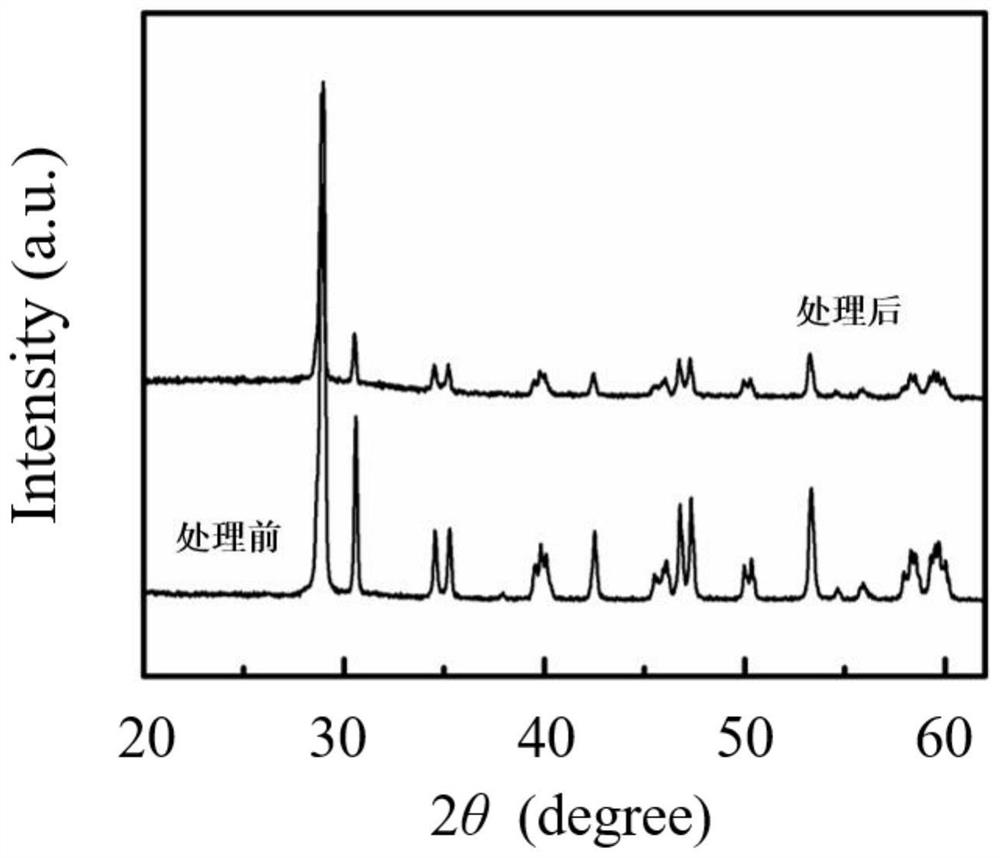

[0046] figure 1 Green BiVO obtained by the method of this example 4 Th...

Embodiment 3

[0051] The present embodiment provides a preparation method of green bismuth vanadate particles, comprising the following steps:

[0052] (1) The yellow monoclinic BiVO 4 The particles (particle size 200 nm) were preheated in a muffle furnace at 200° C. to clean their surfaces.

[0053] (2) The preprocessed BiVO 4 Compression is performed on a quartz glass substrate, and the surface fluctuation error range of the sample after compression is guaranteed to be within -0.1 to 0.1 mm.

[0054] (3) BiVO using laser 4 The irradiation treatment was performed for 8s, and the parameters of the laser were selected as: wavelength 532nm; power 1W; frequency 1000Hz. The pulse width of the laser is 8 ns.

[0055] (4) BiVO after one irradiation in (3) 4 The particles were re-mixed uniformly, and steps (2) and (3) were repeated for a total of 6 times to obtain green uniform BiVO 4 particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com