A method for denitrification of landfill leachate

A landfill leachate and denitrification technology, applied in chemical instruments and methods, microbial-based methods, biochemical equipment and methods, etc., can solve the problems of high infrastructure investment costs, large surplus sludge production, and large carbon source dosage and other problems, to achieve the effect of speeding up film formation, strengthening biological removal effect, and reducing CODcr

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

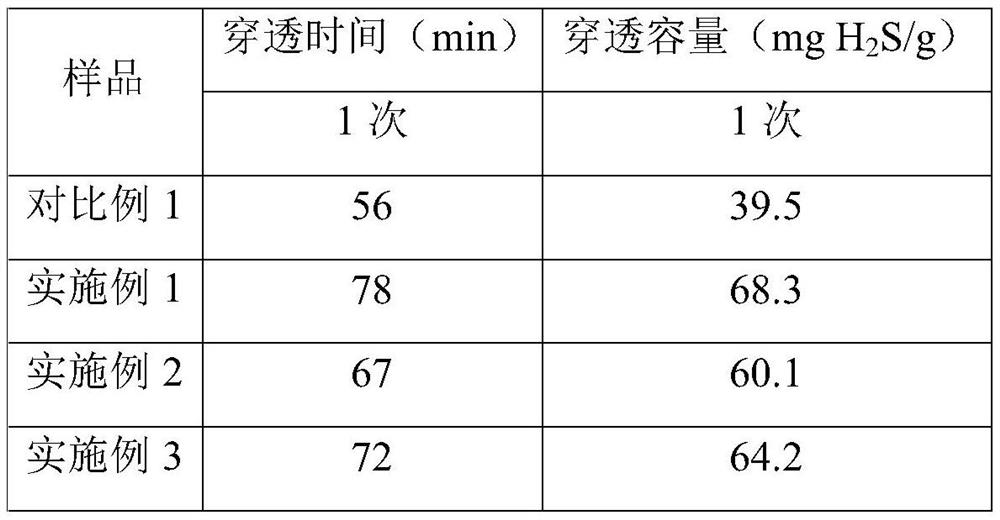

Embodiment 1

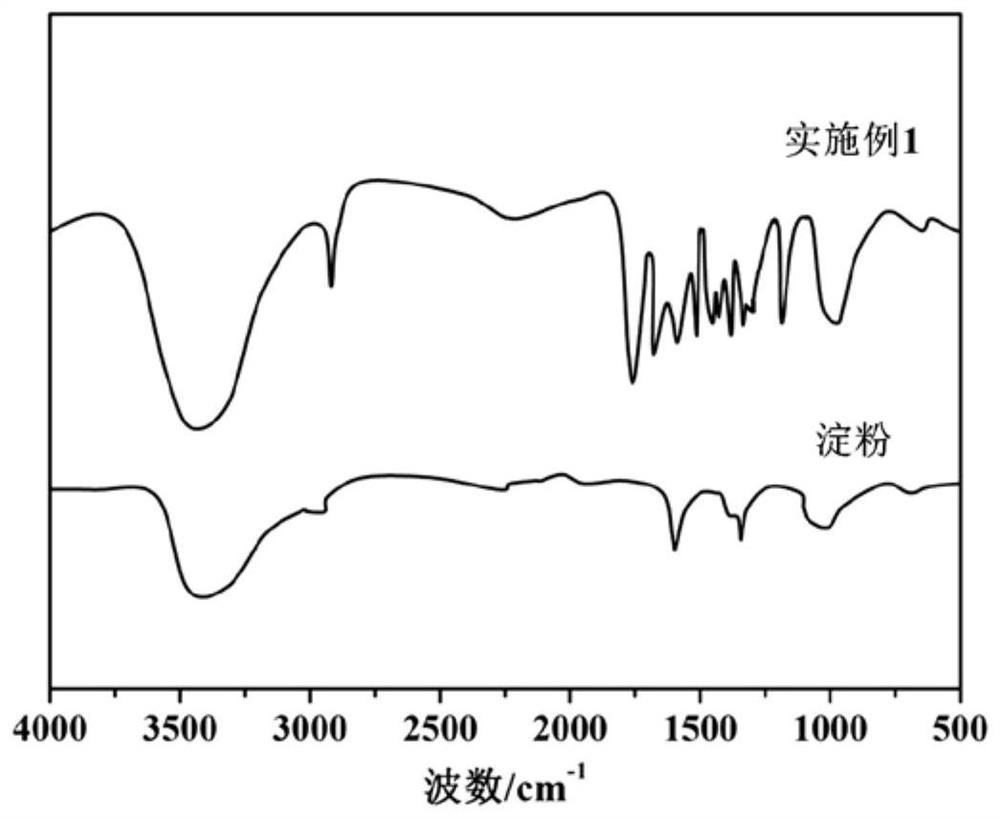

[0044] Preparation of modified starch:

[0045] The starch was weighed and placed in a three-necked flask, 20 mL of dimethylacetamide (DMAc) was added, stirred and dispersed at room temperature, heated to 130 ° C under nitrogen protection to form a homogeneous solution, and then added DMAP (with a mass ratio of starch of 0.1: 1) Activating the hydroxyl group for 1 h, while mixing 3-nitro-4-methylamino-benzoyl chloride (the molar ratio of 3-nitro-4-methylamino-benzoyl chloride and starch glucose group is 0.6:1) In DMAc, add dropwise to the homogeneous solution after the activated hydroxyl group, react at 100 °C, after the end, add the solution dropwise to 10 times excess ice ethanol to precipitate the product, and wash with ethanol three times to collect the final product, put it in a vacuum The modified starch was obtained by drying in a drying oven for 48 hours, and the yield was 87.4%.

[0046] Preparation of Biofillers:

[0047] Using water-soluble polyurethane (WPU) solu...

Embodiment 2

[0049] The difference between the preparation of modified starch and Example 1 is that the molar ratio of 3-nitro-4-methylamino-benzoyl chloride to starch glucose group is 0.7:1, and the yield is 82.5%.

[0050] The preparation of biofiller was the same as in Example 1.

Embodiment 3

[0052] The difference between the preparation of modified starch and Example 1 is that the molar ratio of 3-nitro-4-methylamino-benzoyl chloride to starch glucose group is 0.65:1, and the yield is 85.1%.

[0053] The preparation of biofiller was the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com