Preparation method and application method of super-hydrophobic antibacterial magnesium oxychloride powder coating

A technology of powder coating and application method, applied in the direction of powder coating, coating, cement coating, etc., can solve the problems of reducing the antibacterial performance of materials, toxic environment, pollution, etc., achieve long-term effective antibacterial performance, avoid pollution, and inhibit hygroscopicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: Preparation of superhydrophobic antibacterial magnesium oxychloride powder coating

[0039] Material:

[0040] Light-burned magnesia: MgO, activity 61.2%, Shanghai Qiren Chemical Co., Ltd.; hydroxyl-terminated polydimethylsiloxane (PDMS): viscosity 10000cP, Dow Corning Company; tetraethyl orthosilicate (TEOS): analytically pure, Tianjin Bodie Chemical Co., Ltd.; dibutyltin dilaurate (DD): analytically pure, Siping Fine Chemicals Co., Ltd.; magnesium chloride hexahydrate (MgCl 2 ·6H 2 O): analytically pure, Chengdu Kelong Chemicals Co., Ltd.; Dimethyloctadecyl [3-(trimethoxysilyl) propyl] ammonium chloride (QAS): analytically pure, Dow Corning; used in experiments Water was deionized water made in the laboratory.

[0041] Preparation:

[0042] (1) According to the molar ratio MgO:MgCl 2 ·6H 2 O:H 2O=7.56:1:7.51 Add MgO and MgCl to the JJ-5 planetary mortar mixer 2 ·6H 2 O and H 2 O, stirred rapidly for 10 minutes to obtain MOC cement matrix slurry...

Embodiment 2

[0046] Embodiment 2: Characterization of superhydrophobic antibacterial magnesium oxychloride powder coating

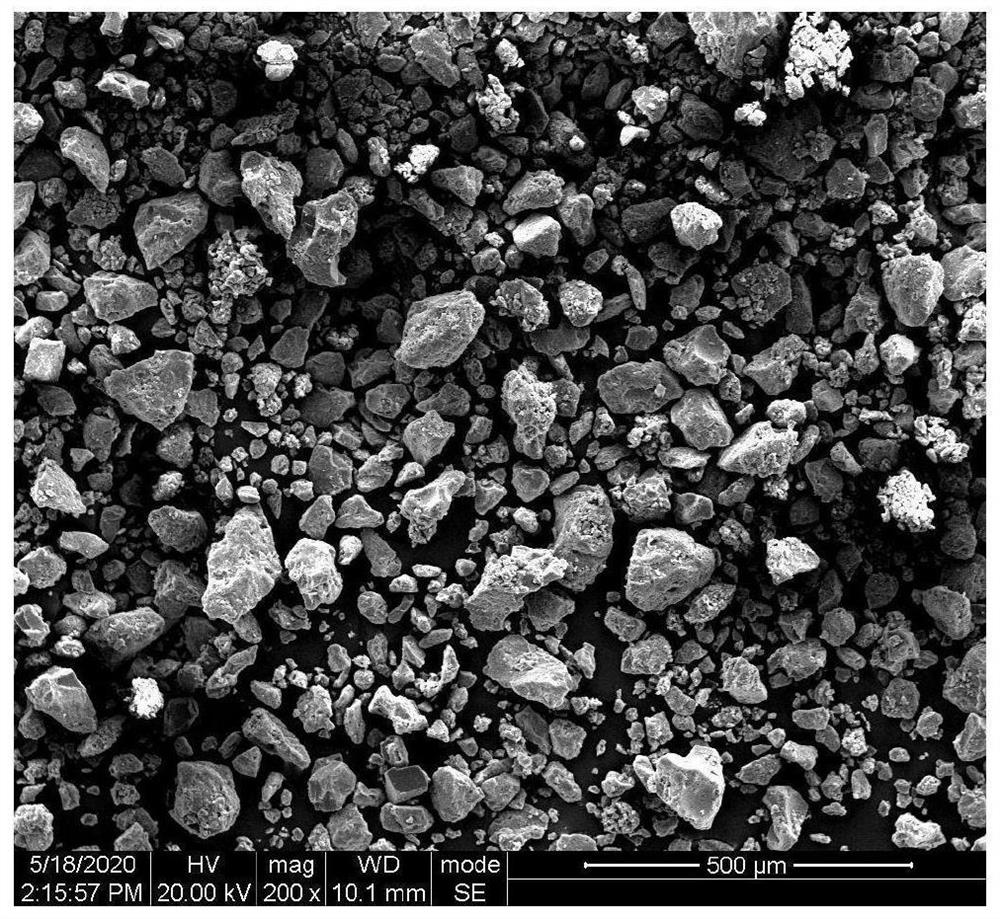

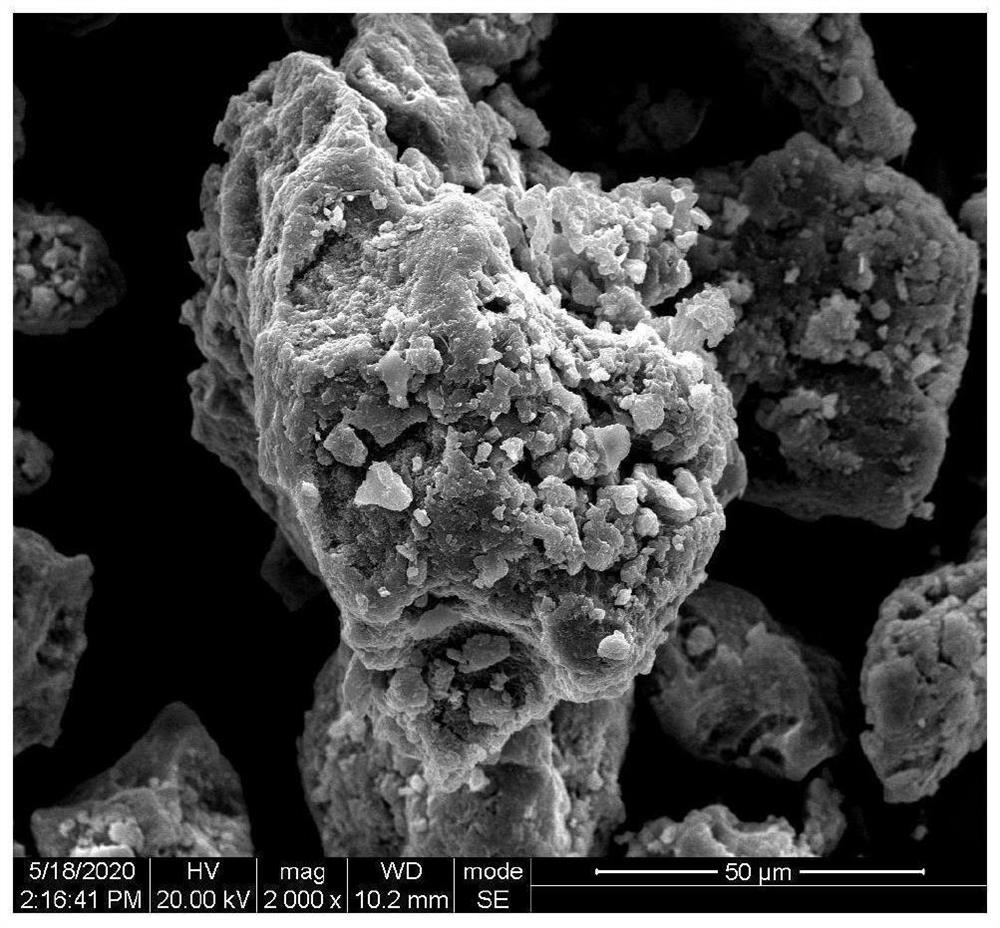

[0047] figure 1 It is the SEM figure of the superhydrophobic antibacterial magnesium oxychloride powder coating prepared in embodiment 1, figure 2 It is the particle surface morphology figure of the superhydrophobic antibacterial magnesium oxychloride powder coating prepared in embodiment 1, as can be seen from the SEM figure, the magnesium oxychloride powder particle size after grinding comprises nanometer to submillimeter level, and particle surface is microcosmic rough structure. When used as a coating, a sieve can be used as needed to select the powder of the required size.

Embodiment 3

[0048] Embodiment 3: the application of superhydrophobic antibacterial magnesium oxychloride powder coating on metal steel plate

[0049] Coating powder: superhydrophobic / antibacterial magnesium oxychloride powder prepared in Example 1.

[0050] Application of superhydrophobic antibacterial magnesium oxychloride powder coating on metal steel plates:

[0051] 1. Metal substrate pretreatment: Use a sandblasting machine to sandblast the surface of the metal plate (50*50mm), then place the metal plate in an ethanol solution for ultrasonic cleaning, remove grease and stains on the surface of the metal plate, and place Heating in an oven at 150°C for standby;

[0052] 2. Coating preparation: evenly spread a layer of strong adhesive on the metal plate, and then spray the powder evenly on the surface of the metal plate with a powder sprayer.

[0053] Coating performance test:

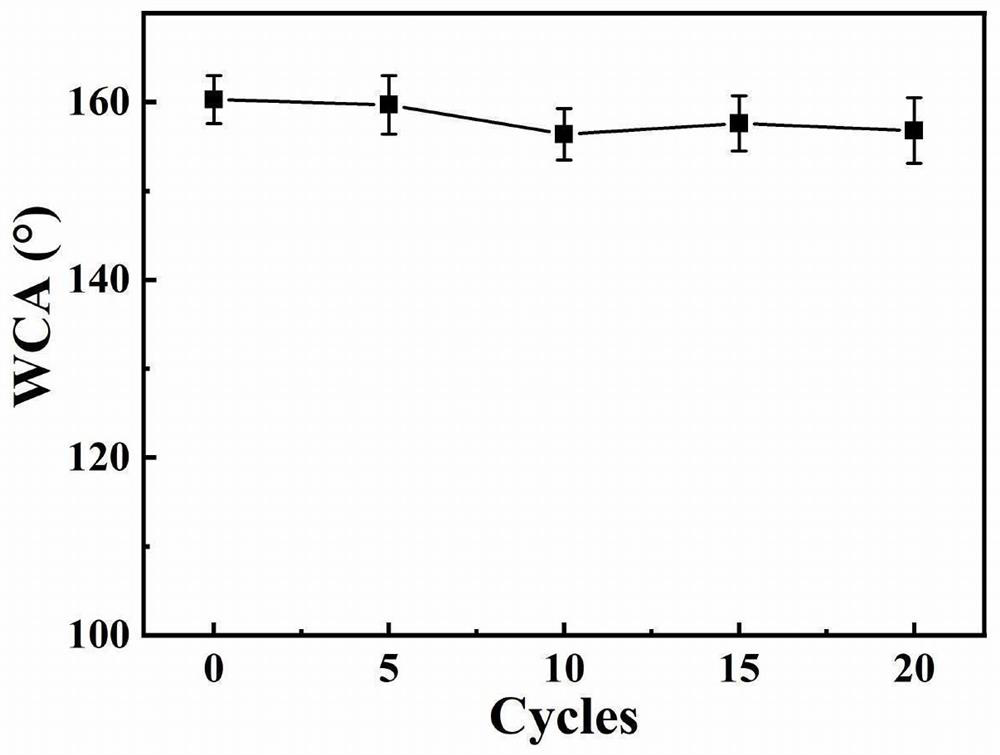

[0054] (1) Superhydrophobic performance test: use a contact angle meter to measure the contact angle of w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com