FeCoMoPC series amorphous alloy for alkaline fully-decomposed water and preparation method of amorphous alloy

An amorphous alloy, water splitting technology, applied in non-precious metal oxide coating, electrolysis process, electrolysis components, etc., can solve the problems of small active specific surface area of strips, poor electrocatalytic effect, etc. Less harmful, the effect of increasing the active specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

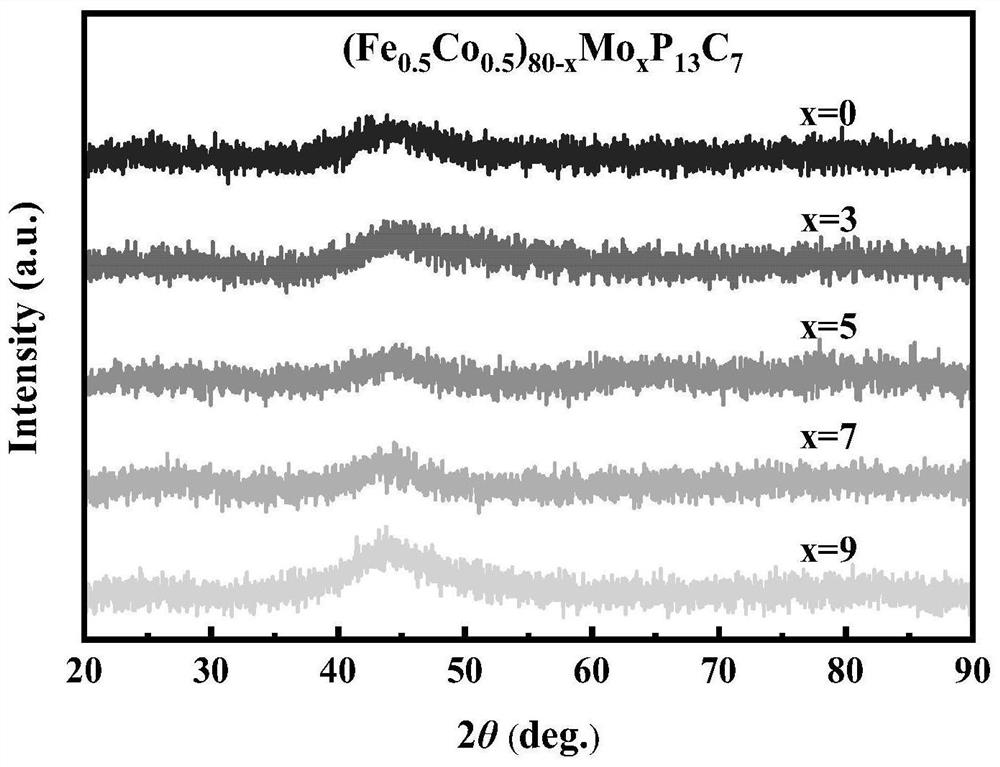

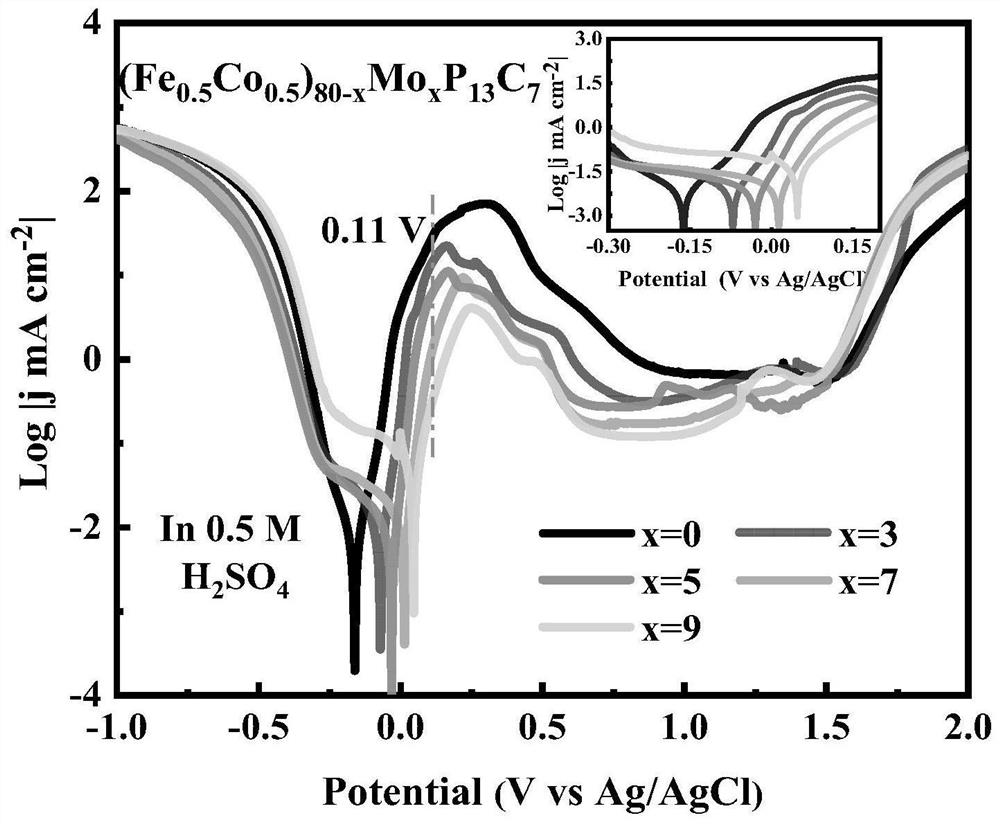

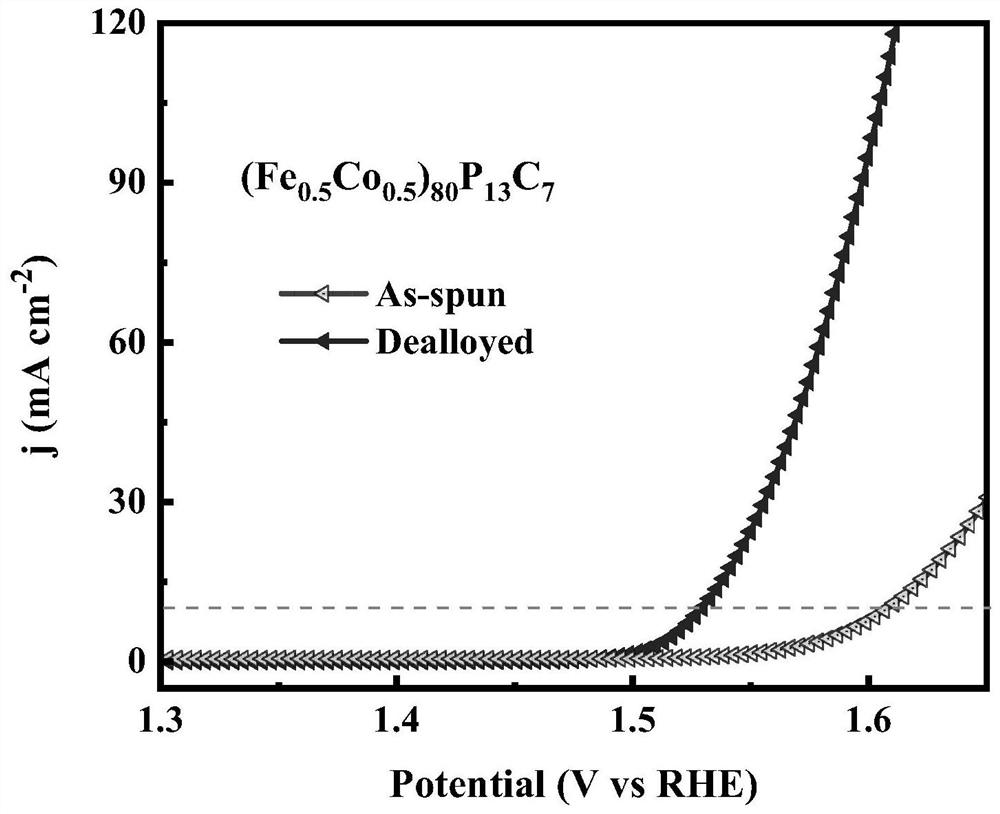

[0026] (1) Preparation (Fe 0.5 co 0.5 ) 80-x Mo x P 13 C 7 (x=0,3,5,7,9) amorphous alloy strip, the preparation process is as follows:

[0027] ①Convert and weigh the required high-purity Fe, Co, Mo, FeP, and C according to the atomic percentage. Under the atmosphere of high-purity argon, first melt Fe, Co, Mo, and C into alloy ingots by electric arc. Remelt at least 4 times to ensure a homogeneous alloy composition, then mix the alloy ingot with FeP for induction melting to obtain (Fe 0.5 co 0.5 ) 80-x Mo x P 13 C 7 (x=0,3,5,7,9) master alloy ingots.

[0028] ②Using a single-roll stripping equipment, the master alloy ingot (Fe 0.5 co 0.5 ) 80-x Mo x P 13 C 7 (x=0,3,5,7,9) Induction melting is carried out in an argon atmosphere, and the molten metal is sprayed onto a copper roller with a speed of 3600-4200 rpm through an instantaneous pressure difference (0.02MPa) to obtain a wide 1-2mm, thick 20-30μm (Fe 0.5 co 0.5 ) 80-x Mo x P 13 C 7 alloy strip.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric potential | aaaaa | aaaaa |

| Corrosion time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com