A blue light perovskite light-emitting diode and preparation method thereof

A light-emitting diode and perovskite technology, which is applied in semiconductor/solid-state device manufacturing, organic semiconductor device materials, electric solid-state devices, etc., can solve the problem of low photoluminescence quantum yield and red-shifted emission wavelength of perovskite light-emitting films , complex preparation process and other issues, to achieve the effect of reducing crystal surface defects, high external quantum efficiency, and simple processing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A blue light perovskite light-emitting diode, the preparation method of which comprises the following steps:

[0045] 1) ultrasonically clean the glass substrate coated with the ITO layer with isopropyl alcohol, deionized water containing detergent, pure deionized water and isopropyl alcohol in turn, then place the substrate in an oven for drying, and then use ultraviolet and Ozone treatment for 5min, and then spin-coating 50% PEDOT:PSS aqueous solution on the ITO layer of the glass substrate at a spin coating speed of 4000rpm, and then annealed at 120°C for 20min to form a hole transport layer with a thickness of 20nm;

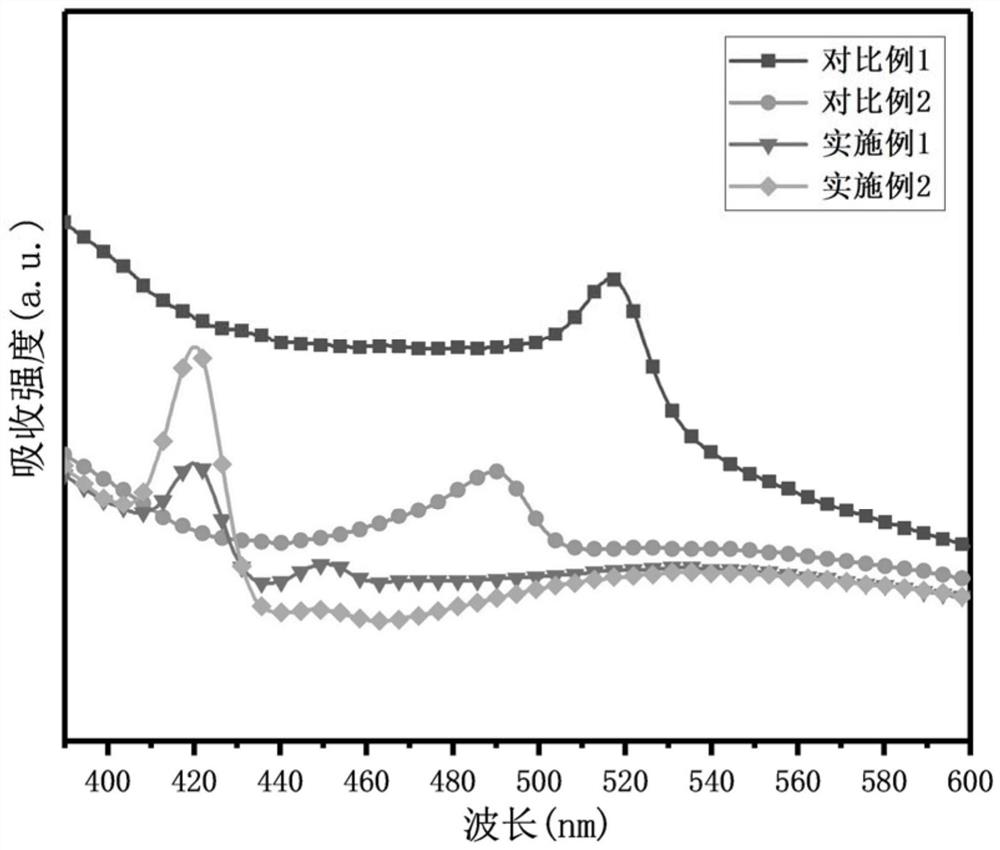

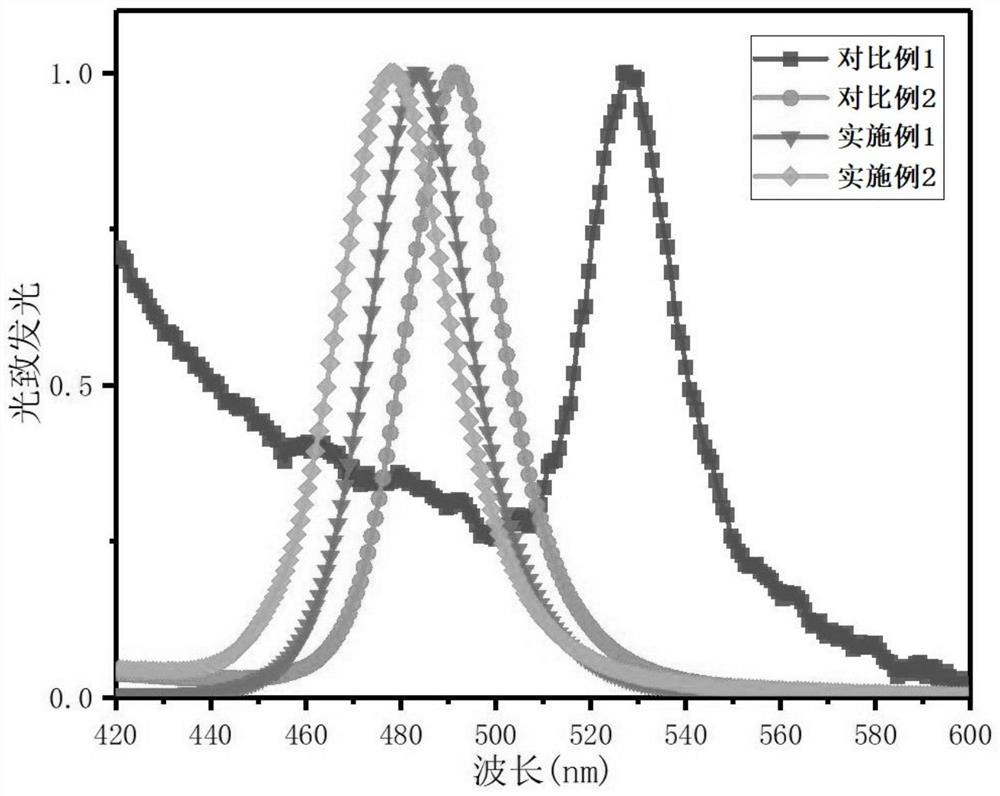

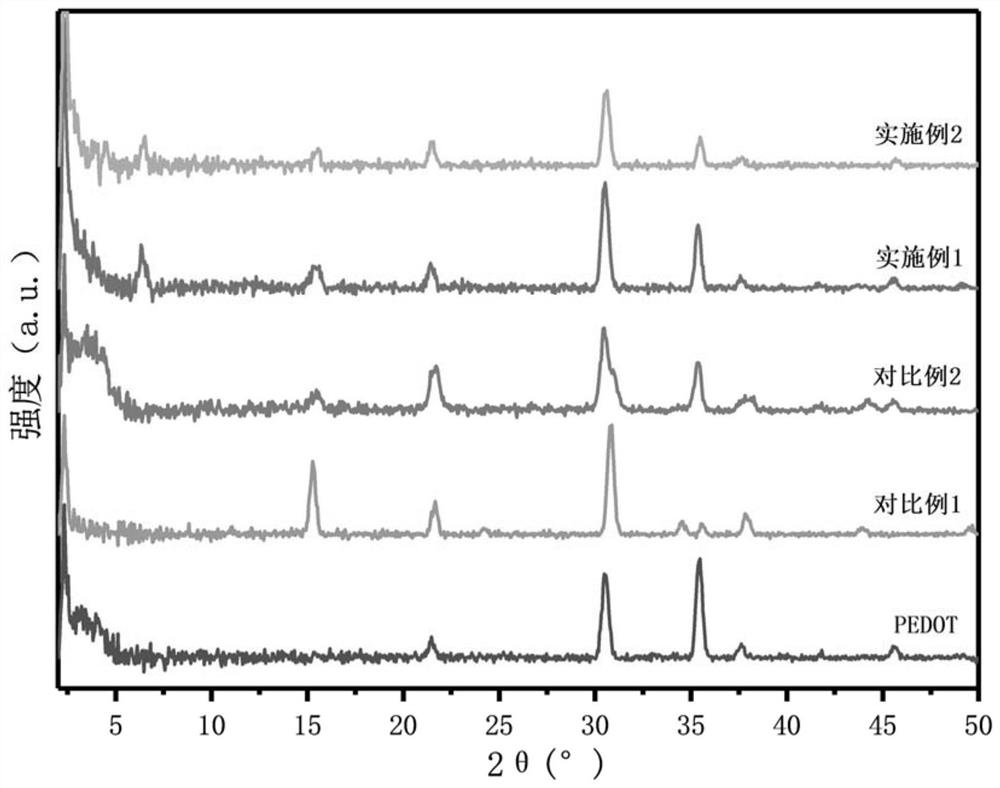

[0046] 2) 42.6 mg of CsBr, 73.4 mg of PbBr 2 , 18.5 mg of isobutylamine hydrobromide and 25.6 mg of 1-phenyl biguanide hydrochloride were dispersed in 1 mL of DMSO to make a perovskite precursor solution, and then the perovskite precursor solution was spin-coated in the air. On the hole transport layer, spin coating at a speed of 500rpm for 5s, spin a...

Embodiment 2

[0049]A blue light perovskite light-emitting diode, the preparation method of which comprises the following steps:

[0050] 1) ultrasonically clean the glass substrate coated with the ITO layer with isopropyl alcohol, deionized water containing detergent, pure deionized water and isopropyl alcohol in turn, then place the substrate in an oven for drying, and then use ultraviolet and After ozone treatment for 5min, spin-coating 50% PEDOT:PSS aqueous solution on the ITO layer of the glass substrate at a spin coating speed of 4000rpm, and then annealing at 120°C for 20min to form a hole transport layer with a thickness of 20nm;

[0051] 2) 42.6 mg of CsBr, 73.4 mg of PbBr 2 , 24.6 mg of isobutylamine hydrobromide and 25.6 mg of 1-phenyl biguanide hydrochloride were dispersed in 1 mL of DMSO to make a perovskite precursor solution, and then the perovskite precursor solution was spin-coated in the air. On the hole transport layer, spin coating at a speed of 500rpm for 5s, spin at a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com