Film-forming material for lithography, film-forming composition for lithography, lower layer film for lithography, and pattern-forming method

A composition and lithography technology are applied in the direction of photosensitive material processing, micro-lithography exposure equipment, photosensitive materials used in photomechanical equipment, etc., which can solve the problems of resist pattern collapse, resolution problems, and difficulty in obtaining it, and achieve Excellent film flatness and embedding characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0219] Hereinafter, although an Example and a comparative example demonstrate this invention in more detail, this invention is not limited to these examples at all.

[0220] [molecular weight]

[0221] The molecular weight of the synthesized resin was measured by GPC-MS analysis using Acquity UPLC / MALDI-Synapt HDMS manufactured by Water Corporation.

[0222] [Evaluation of heat resistance]

[0223] Using the EXSTAR6000TG-DTA device manufactured by SII Nanotechnology Inc., put about 5 mg of the sample into an aluminum non-sealed container, and raise the temperature to 500°C at a temperature increase rate of 10°C / min in a nitrogen (100ml / min) flow, thereby measuring the heat Weight reduction. From a practical point of view, the following A or B evaluation is preferable. When rated as A or B, it has high heat resistance and can be applied to high temperature baking.

[0224]

[0225] A: The thermogravimetric reduction at 400°C is less than 10%

[0226] B: The thermogravime...

Synthetic example 1

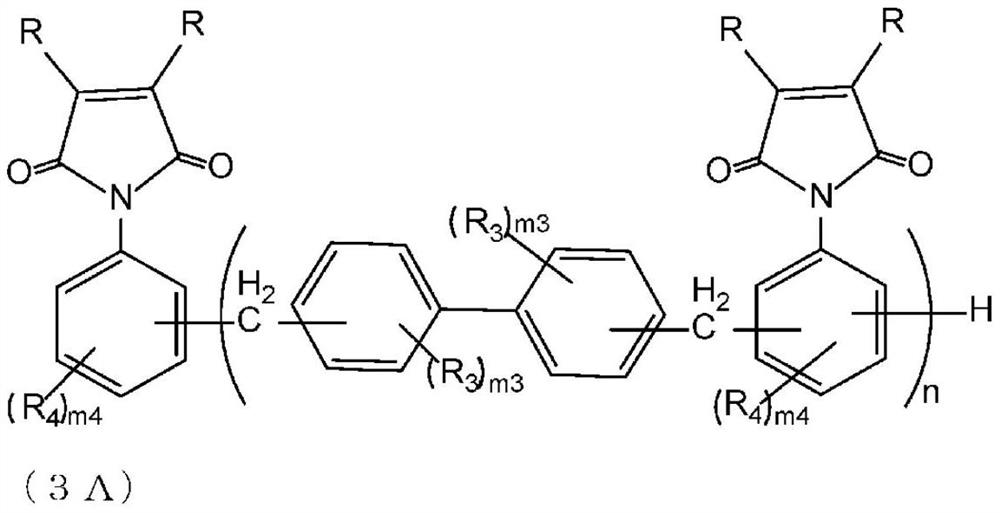

[0234] (Synthesis Example 1) Synthesis of BMI Citraconimide Resin

[0235] A container with an inner volume of 100 ml equipped with a stirrer, a condenser, and a burette was prepared. Into this container, 2.4 g of diaminodiphenylmethane oligomer obtained as a follow-up test of Synthesis Example 1 of Japanese Patent Application Laid-Open No. 2001-26571, 4.56 g (44.0 mmol) of citraconic anhydride (manufactured by Kanto Chemical Co., Ltd.) ), dimethylformamide 40ml and toluene 60ml, add p-toluenesulfonic acid 0.4g (2.3mmol) and polymerization inhibitor BHT 0.1g, prepare reaction solution. The reaction solution was stirred at 110° C. for 8.0 hours to react, and the produced water was recovered in a Dean-Stark trap under azeotropic dehydration. Next, after cooling the reaction liquid to 40 degreeC, it dripped at the beaker which put 300 ml of distilled water, and deposited the product. After filtering the obtained slurry solution, the residue was wash|cleaned with methanol, and 4...

Synthetic example 2

[0238] (Synthesis example 2) Synthesis of BAN citraconimide resin

[0239] A container with an inner volume of 100 ml equipped with a stirrer, a condenser, and a burette was prepared. In this container, 6.30 g of biphenyl aralkyl type polyaniline resin (product name: BAN, manufactured by Nippon Kayaku Co., Ltd.), 4.56 g (44.0 mmol) of citraconic anhydride (manufactured by Kanto Chemical Co., Ltd.), dimethyl 40ml of methyl formamide and 60ml of toluene were added, 0.4g (2.3mmol) of p-toluenesulfonic acid and 0.1g of polymerization inhibitor BHT were added to prepare a reaction solution. The reaction liquid was stirred at 110° C. for 6.0 hours to react, and the produced water was recovered in a Dean-Stark trap under azeotropic dehydration. Next, after cooling the reaction liquid to 40 degreeC, it dripped at the beaker which put 300 ml of distilled water, and deposited the product. After filtering the obtained slurry solution, the residue was washed with methanol and subjected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com