Industrial tail gas high-efficiency desulfurizer and preparation method thereof

A technology for industrial tail gas and desulfurization agent, applied in separation methods, chemical instruments and methods, gas treatment and other directions, can solve the problems of low reaction activity of absorbent slaked lime, affecting product storage and application effects, and unstable properties of sodium bicarbonate, etc. Achieve the effect of easy market acceptance, simple structure and strong promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Such as Figure 1-6 As shown, a high-efficiency desulfurizer for industrial tail gas and its preparation method include the following raw materials: taking common baking soda products as raw materials, sodium bicarbonate products, and anti-caking agents with feldspar minerals as main components, and the addition ratio is 0.5-40%.

[0031] Further, feldspar mineral products include orthoclase, albite, anorthite, barium feldspar, barium ice feldspar, microcline, sanidine and all minerals with feldspar as the main component.

[0032] Further, feldspar mineral products can be used alone as an anti-caking agent. When used alone, the proportion of feldspar added is 0.5% or more, that is, the proportion of baking soda in the product is less than 99.5%, and the proportion of feldspar powder is greater than 0.5%.

[0033] A preparation method of an industrial tail gas high-efficiency desulfurizer, comprising the following steps:

[0034] S1: Use ordinary baking soda products a...

Embodiment 1

[0045] Application case of using feldspar alone as anti-caking agent

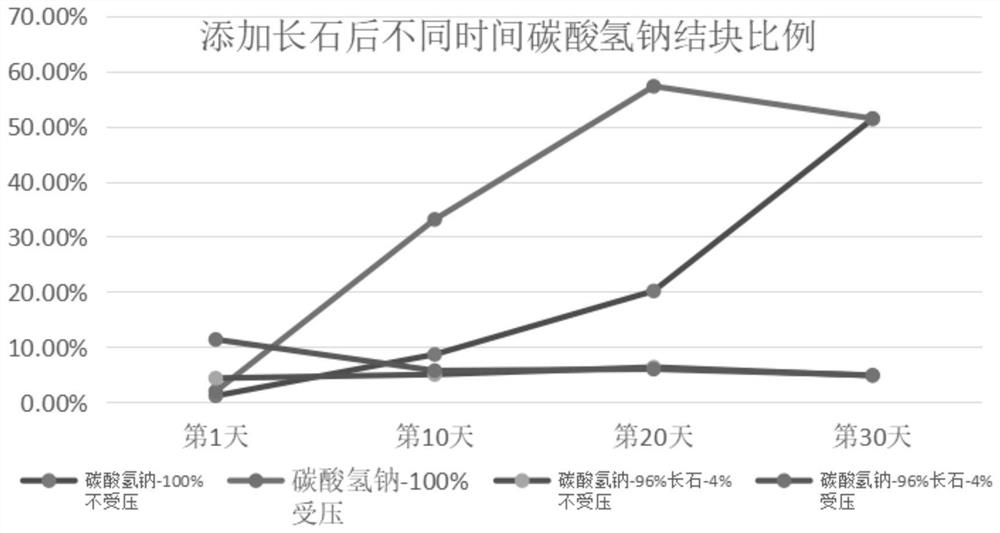

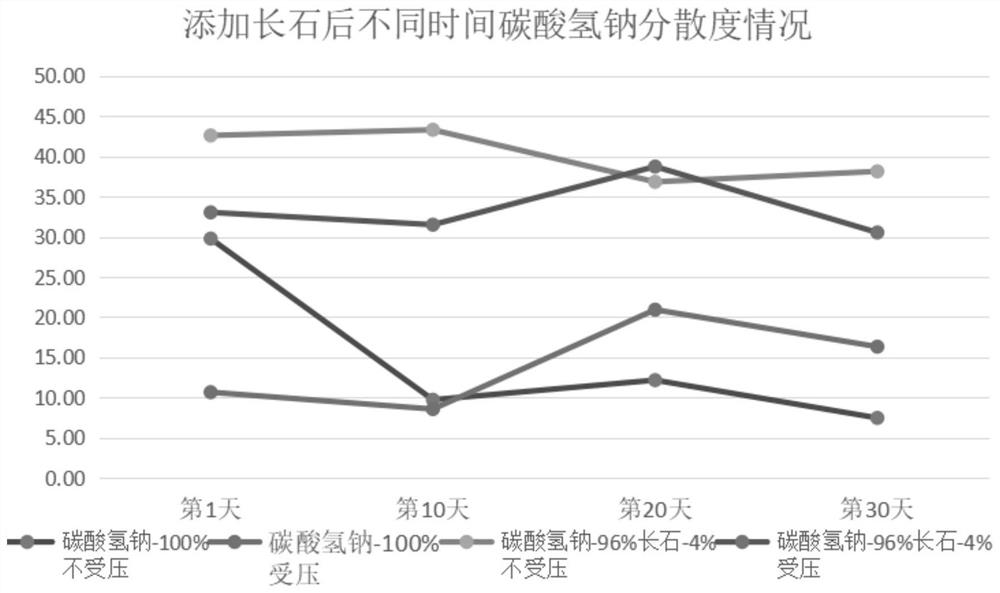

[0046] The proportioning ratio is 4% feldspar, 96% baking soda product, and the D50 value of the product is about 10um. After mixing evenly, it is sealed and stored. One group is under pressure with a pressure of 1000kg / ㎡, and one group is not under pressure; another two groups are used Baking soda products with the same particle size, without adding any anti-caking agent, are sealed and stored, and used as a control group for comparative experiments. One group is under pressure, the pressure is 1000kg / ㎡, and the other group is not under pressure;

[0047] After 1 day, 10 days, 20 days, and 30 days of natural storage, open the product package, take a sample to detect the proportion of product agglomeration, use the +2mm sieve as a reference data, and compare it with the pure sodium bicarbonate product stored in the same state;

[0048] From the comparison results, the effect of using orthoclase as an anti-c...

Embodiment 2

[0051] Application case of using high-efficiency desulfurizer to treat acidic industrial waste gas in cement industry

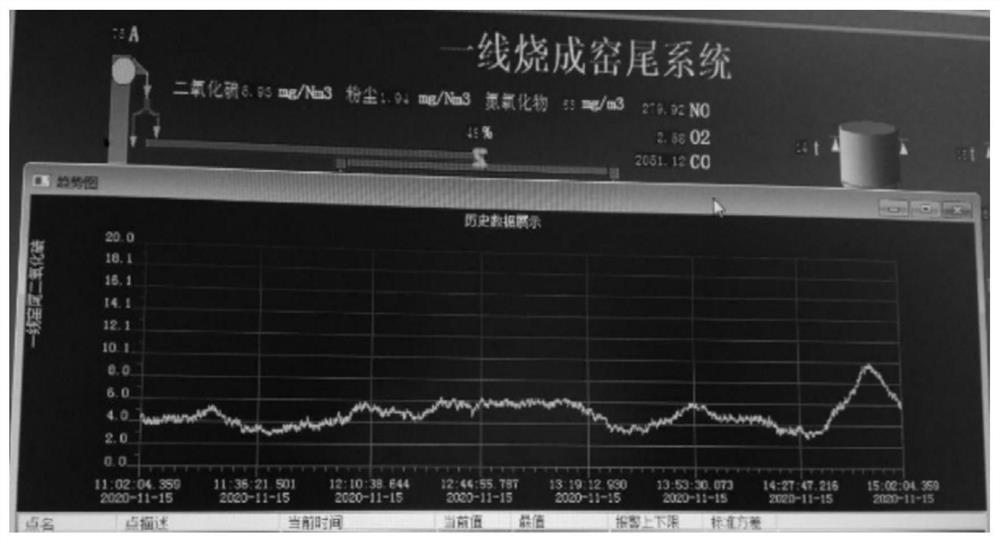

[0052] The production capacity of the production line is 2,500 tons / h. The original process uses calcium hydroxide for treatment, and the dosage is 300kg / h. The concentration of sulfur dioxide in the flue gas can be reduced to 8mg / m 3 , in the grinding state, and the spray tower is in operation, the winter emission standard tends to be stricter, the state requires cement industry enterprises to control production according to the total emission, so the enterprise hopes to reduce the emission standard to near zero, in the condition of calcium hydroxide process In this situation, even if the usage is greatly increased, the concentration of sulfur dioxide cannot be further reduced;

[0053] Use the B100 type high-efficiency desulfurizer product, the main component is baking soda, and the proportion of feldspar powder is 4%. Add this product to the outlet of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com