Submicron or micron monodisperse single crystal conductive gold ball and preparation method thereof

A conductive gold ball, sub-micron technology, applied in the direction of single crystal growth, single crystal growth, metal processing equipment, etc., can solve the problems of high equipment requirements, complex preparation process, high energy consumption, and avoid the use of complex instruments , The preparation process is simple and easy to operate, and the monodispersity is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

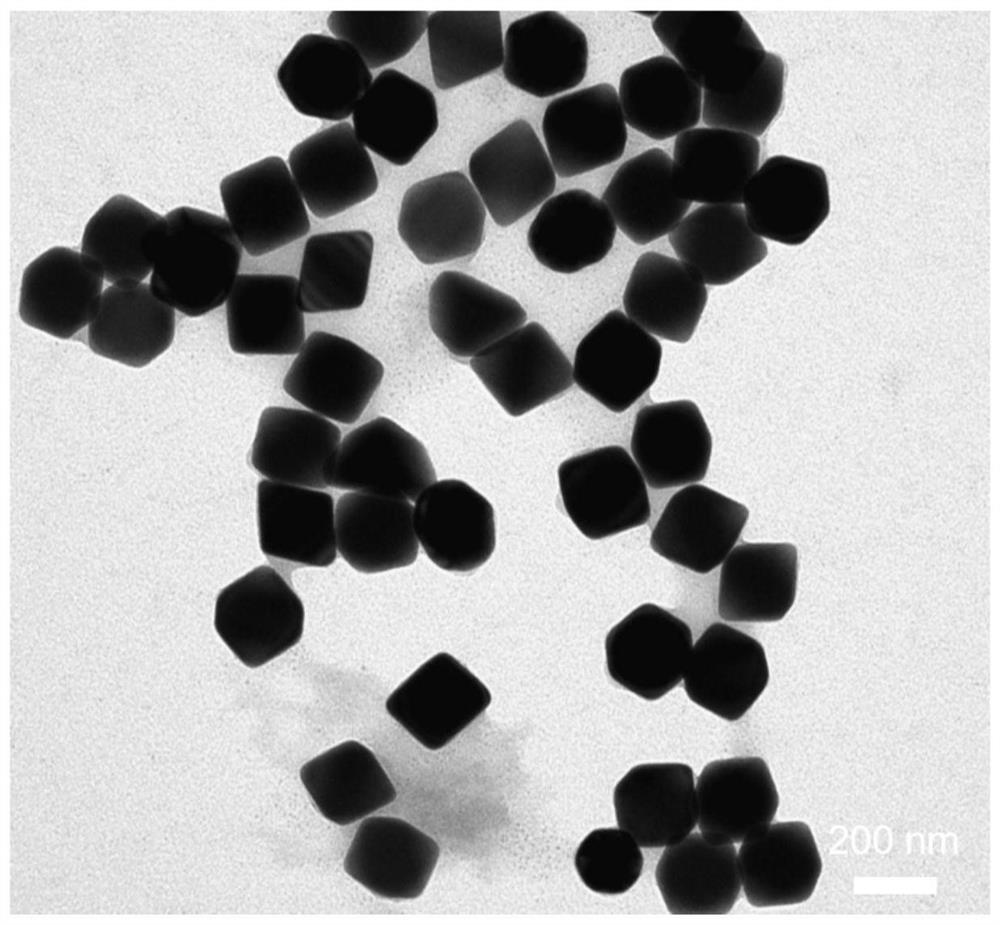

[0022] A method for preparing submicron or micron monodisperse single crystal conductive gold balls may comprise the following steps:

[0023] Step A, adding chloroauric acid, polydiallyldimethylammonium chloride and silver nitrate with a molecular weight of 100,000 to 200,000 to the ethylene glycol solution, so that the concentration of chloroauric acid in the mixed liquid is 0.0005 to 0.002mol / L, the concentration of polydiallyl dimethyl ammonium chloride is 0.01~2mol / L, and react at 180~200°C for 1~2 hours to obtain small-sized monodisperse single crystal conductive gold ball colloid solution (for example: the colloidal solution of small-sized monodisperse single-crystal conductive gold spheres can be a colloidal solution of 100 nanometer monodisperse single-crystal conductive gold spheres). Step B is performed using the colloidal solution of small-sized monodisperse single-crystal conductive gold spheres as a seed solution.

[0024] Step B, adding chloroauric acid and po...

Embodiment 1

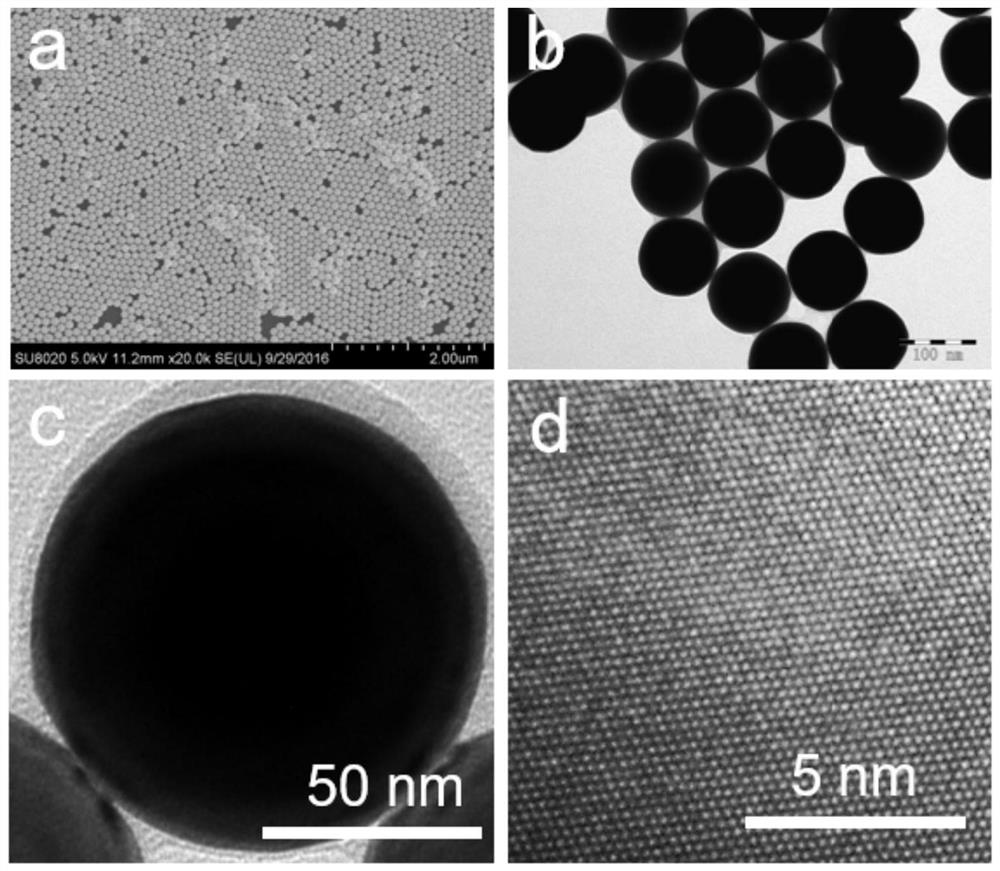

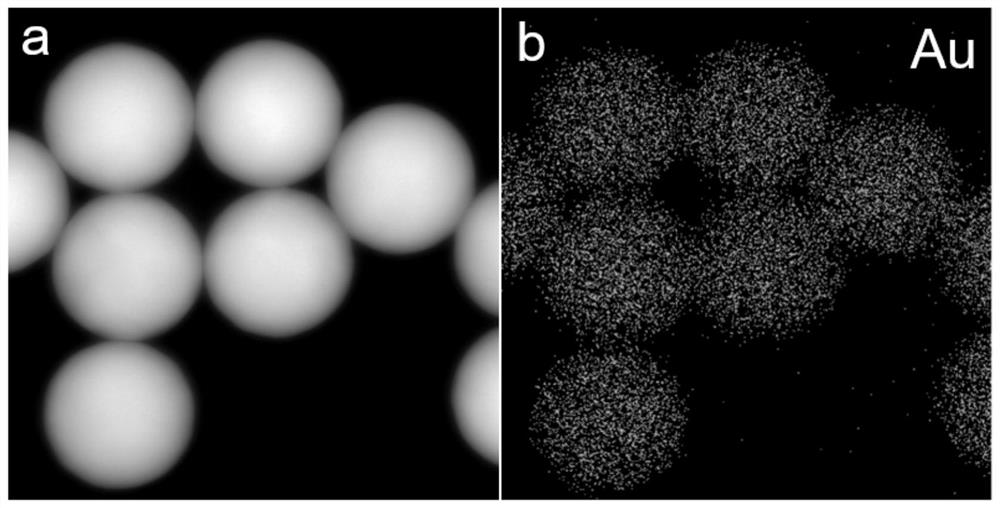

[0036] Such as Figure 5 Shown, a kind of submicron monodisperse monocrystalline conductive gold ball, its preparation method comprises the following steps:

[0037] Step a1, adding chloroauric acid, silver nitrate and polydiallyl dimethyl ammonium chloride (Mw=100000~200000, 20wt%) with a molecular weight of 100000~200000 to 100 milliliters of ethylene glycol solution, after mixing The concentration of chloroauric acid in the liquid is 0.001 mol / liter, the concentration of silver nitrate is 0.01 mmol / liter, and the concentration of polydiallyl dimethyl ammonium chloride is 0.025 mol / liter, and then in an oil bath at 200 ° C Heating and reacting in the pot for 2 hours, and naturally cooling to room temperature, thereby preparing a colloidal solution of 100 nanometer monodisperse single crystal conductive gold spheres.

[0038] Step b1, using the 100 nanometer monodisperse single crystal conductive gold sphere colloid solution prepared in step a1 as the seed liquid, adding chl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com