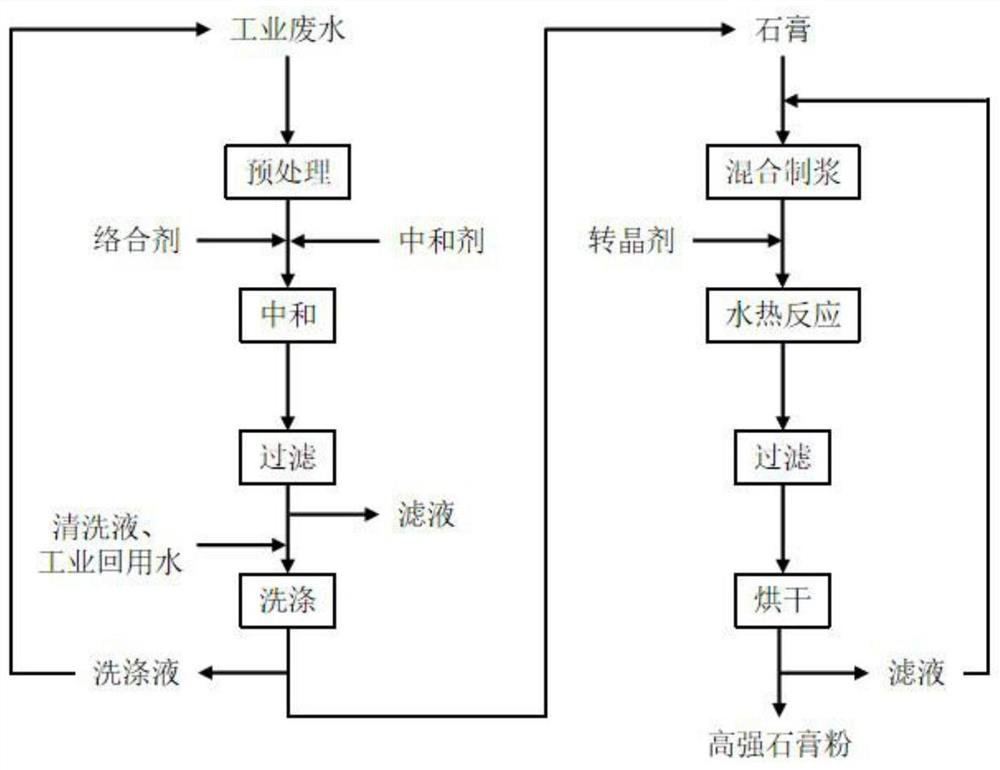

Process for producing high-strength gypsum by using sulfate ions in industrial wastewater

A technology for sulfate ion and industrial wastewater, applied in the chemical industry, calcium/strontium/barium sulfate, sustainable manufacturing/processing, etc. Dealing with difficulty and cost, realizing the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Measure 50L of titanium dioxide wastewater, heat it to 80°C, adjust the pH of the solution to 2 with titanium dioxide waste acid or lime, filter after a period of reaction, then add 5g of o-phenanthroline and 2300g of calcium carbonate to the filtrate for neutralization, adjust The pH of the solution is 3, and after a period of reaction, it is filtered, and the filter cake is washed with 15000 g of cleaning solution and 15000 g of industrial reuse water to obtain gypsum. Mix 4000g of gypsum and 16000g of water, add 4g of sodium citrate, and pump it to the reaction kettle, control the reaction temperature to 150°C, the pH of the solution to 3, and the stirring speed to 300rpm. After 3 hours of reaction, filter the material. High-strength gypsum can be obtained by drying. After analysis, the whiteness of gypsum is 97%, the sieve allowance of high-strength gypsum powder is 3.4%, the initial setting time is 16min, the final setting time is 24min, the 2h flexural strength of...

Embodiment 2

[0030] Measure 50L of titanium dioxide wastewater, heat it to 90°C, adjust the pH of the solution to 1.5 with titanium dioxide waste acid or lime, filter after a period of reaction, then add 10g of o-phenanthroline and 2300g of calcium carbonate to the filtrate for neutralization, adjust The pH of the solution is 2.5, and after a period of reaction, it is filtered, and the filter cake is washed with 20,000 g of cleaning solution and 15,000 g of industrial reuse water to obtain gypsum. Mix 4000g of gypsum and 16000g of water, add 6g of sodium citrate, and pump it to the reactor, control the reaction temperature to 170°C, the pH of the solution to 8, and the stirring speed to 200rpm. High-strength gypsum can be obtained by drying at high temperature. After analysis, the whiteness of gypsum is 98%, the sieve allowance of high-strength gypsum powder is 2.3%, the initial setting time is 12min, the final setting time is 20min, the 2h flexural strength of high-strength gypsum powder ...

Embodiment 3

[0032] Measure 50L of titanium dioxide wastewater, heat it to 80°C, adjust the pH of the solution to 2 with titanium dioxide waste acid or lime, filter after a period of reaction, then add 4g of ethylenediaminetetraacetic acid and 2300g of calcium carbonate to the filtrate for neutralization, Adjust the pH of the solution to 3.5, filter after reacting for a period of time, and wash the filter cake with 15000 g of cleaning solution and 15000 g of industrial reuse water to obtain gypsum. Mix 4,000g of gypsum and 16,000g of water, add 3g of sodium succinate, and pump it to the reactor, control the reaction temperature to 140°C, the pH of the solution to 9, and the stirring speed to 400rpm, and filter the material after 4 hours of reaction. High-strength gypsum powder can be obtained by drying. After analysis, the whiteness of gypsum is 95%, the sieve allowance of high-strength gypsum powder is 4.5%, the initial setting time is 17min, the final setting time is 27min, the 2h flexur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com