Method for treating heavy metal/organic matter combined pollution wastewater by using solid waste biomass carbonized material

A biochar and composite pollution technology, applied in chemical instruments and methods, water pollutants, separation methods, etc., can solve the problems of efficiency decline, microporous structure unfavorable removal of macromolecular organic pollutants, etc., and achieve the goal of improving governance efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Solid Waste Biomass Carbonization Material Efficiently Removes Pb 2+ / TC compound pollution

[0029] Preparation of solid waste biomass carbonization material, the steps are as follows:

[0030] 1) Wash the collected solid waste raw banana peel with ultrapure water several times to remove dirt, and then dry it in an oven at 105 °C for 12 h; use a pulverizer to crush the dried banana peel to 100 mesh, Soak the crushed banana peel in normal water temperature for 24 hours, filter and dry at 80°C for 12 hours to obtain dry powder;

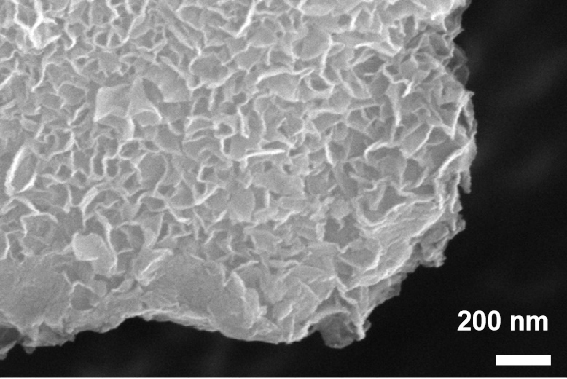

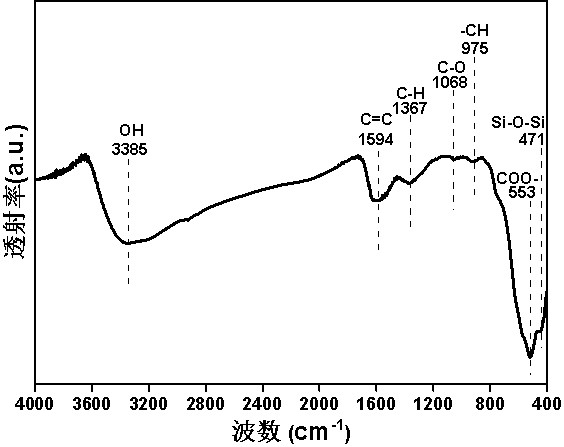

[0031] 2) Add the dried powder obtained in step 1) to the pre-prepared LiCl-ZnCl at a mass ratio of 1:2 2 In mixed salt (pre-prepared LiCl-ZnCl 2 Mixed salt refers to LiCl and ZnCl 2 The weight ratio is 1:1, and the uniform mixed salt is ground through a 300-mesh sieve), and the mixed material is put into a tube furnace, under N 2 Under atmosphere, react at 350 ℃ for 2 h; take it out and place it in 0.1M HCl solution and stir for ...

Embodiment 2

[0045] Example 2 Solid Waste Biomass Carbonization Material Efficiently Treats Pb 2+ / TC pollution.

[0046] The solid biomass carbonization material prepared in embodiment 2 is applied to the Pb in the control water body 2+ and tetracycline (TC) pollution, the specific process is as follows:

[0047] S1: Using ultrapure water as the solvent, prepare the concentration of 200 mg / L Pb respectively 2+ and a solution of 50 mg / L TC. Within the tolerance range of ±0.2, use 0.1 M NaOH and HNO respectively 3 solution to adjust the pH value of the solution, corresponding to the Pb 2+ The solution was adjusted to pH = 7 and the TC solution was adjusted to pH = 3; respectively, 20 mL of the prepared Pb 2+ and TC solution, each adding 10 mg of the solid waste biomass carbonized material prepared in Example 1, adding 10 μL of 5 mM NaNO 3 As a background electrolyte, it was rotated and shaken on a 70 rpm digitally controlled rotary mixer for 48 h, so that the added solid biomass carbo...

Embodiment 3

[0049] Example 3 Efficient Treatment of Solid Waste Biomass Carbonization Materials Containing Pb 2+ / TC polluted printing and dyeing wastewater.

[0050] The solid waste biomass carbonization material prepared in Example 3 is applied to the treatment of heavy metal / new organic compound pollution, and the specific process is as follows:

[0051] S1: Take actual printing and dyeing wastewater samples to further evaluate the prepared solid waste biomass carbonization materials. Set the Pb in the actual water sample 2+ and TC were added at concentrations of 200 mg / L (pH = 7) and 50 mg / L (pH = 3), respectively. 20 mL printing and dyeing wastewater water sample, add 10 mg of biochar prepared in Example 1, add 10 μL of 5 mM NaNO 3 As the background electrolyte, it was rotated and shaken on a 70rpm digitally controlled rotary mixer for 48 hours, so that the added solid waste biomass carbonization material could fully absorb the pollutants in the water. After 48 hours of adsorptio...

PUM

| Property | Measurement | Unit |

|---|---|---|

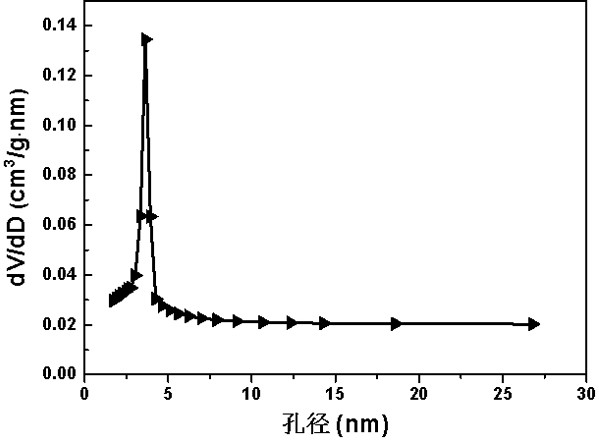

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com