Halogen-free flame-retardant nylon composite material capable of being subjected to laser marking and preparation method thereof

A nylon composite material and laser marking technology, which is applied in the field of laser marking polymer materials, can solve the problems of red phosphorus flame retardants turning red, failing to meet environmental protection requirements, and affecting product appearance, so as to achieve stable product quality and good laser marking. Marking effect, effect of reducing heat residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

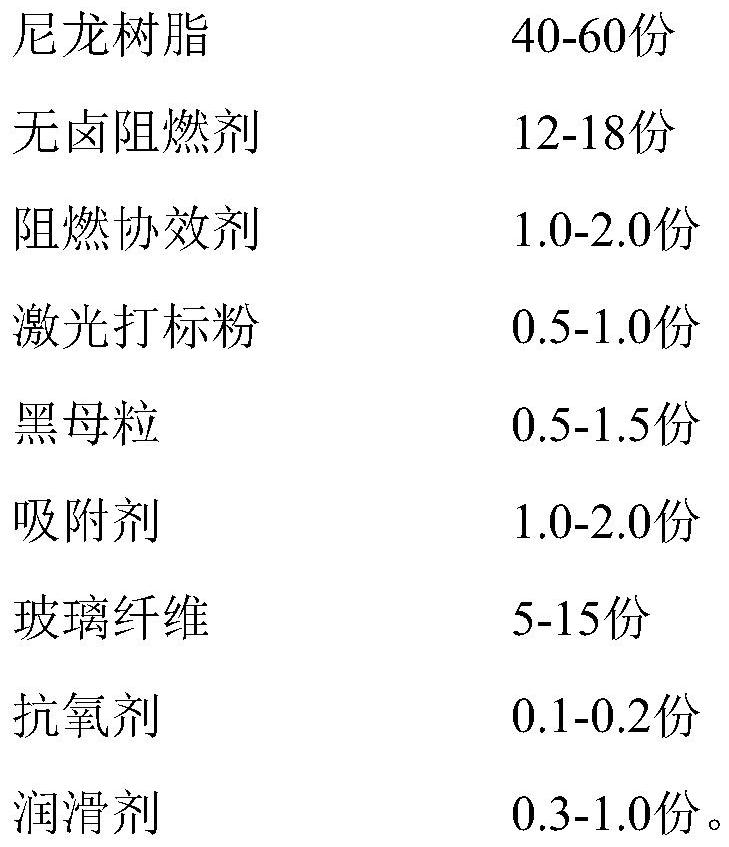

[0042] A laser-markable halogen-free flame-retardant nylon composite material, the nylon composite material includes the following raw materials in parts by weight:

[0043]

[0044] The nylon resin is polyhexamethylene adipamide (PA66), and the intrinsic viscosity of the nylon resin PA66 is 2.7dL / g.

[0045] The halogen-free flame retardant is aluminum diethylphosphinate, and the flame retardant synergist is vinyl functionalized polymethylsilsesquioxane (AR-511A).

[0046] Each part of laser marking powder is a mixture of modified titanium dioxide and montmorillonite in a weight ratio of 1:0.80, wherein the preparation of modified titanium dioxide comprises the following steps:

[0047] Step A1: Mix and stir tetrabutyl titanate, acetic acid, and absolute ethanol at a volume ratio of 10:1:12 to prepare solution A, and then add 0.5 wt% lanthanum nitrate to the volume ratio of ethanol to water In the mixed solution of 10:1, nitric acid was added dropwise to adjust the pH of ...

Embodiment 2

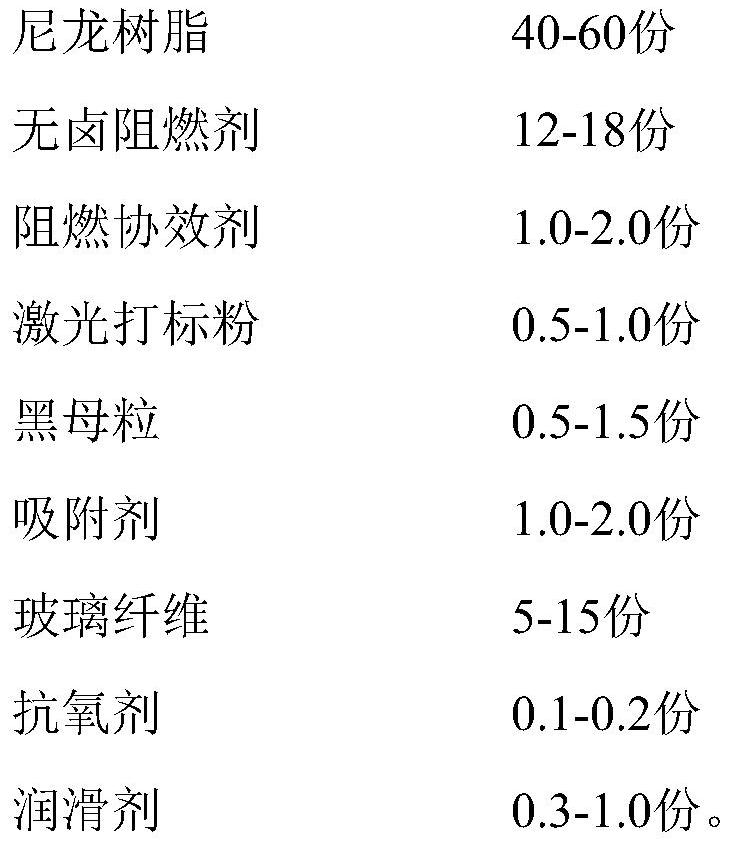

[0060] A laser-markable halogen-free flame-retardant nylon composite material, the nylon composite material includes the following raw materials in parts by weight:

[0061]

[0062] The nylon resin is a mixture of polycaprolactam (PA6) and PA12 (polylaurolactam), the intrinsic viscosity of the nylon resin PA6 is 1.8dL / g, and the intrinsic viscosity of the nylon resin PA12 is 2.2dL / g.

[0063] The halogen-free flame retardant is aluminum methyl ethyl phosphinate, and the flame retardant synergist is polymethylsilsesquioxane (3224).

[0064] Each part of laser marking powder is a mixture of modified titanium dioxide and montmorillonite with a weight ratio of 1:0.85, wherein the preparation of modified titanium dioxide comprises the following steps:

[0065] Step A1: Mix and stir tetrabutyl titanate, acetic acid, and absolute ethanol at a volume ratio of 10:2:14 to prepare solution A, and then add cerium nitrate with a doping amount of 0.5wt% to the volume ratio of ethanol to...

Embodiment 3

[0078] A laser-markable halogen-free flame-retardant nylon composite material, the nylon composite material includes the following raw materials in parts by weight:

[0079]

[0080] The nylon resin is a mixture of polyhexamethylene adipamide (PA66) and polydecanediamide sebacamide (PA1010), the intrinsic viscosity of the nylon resin PA66 is 2.2dL / g, and the nylon resin PA1010 The intrinsic viscosity is 1.6dL / g.

[0081] The halogen-free flame retardant is aluminum diethylphosphinate, and the flame retardant synergist is polymethylsilsesquioxane (3224).

[0082] Each part of laser marking powder is a mixture of modified titanium dioxide and montmorillonite in a weight ratio of 1:0.9, wherein the preparation of modified titanium dioxide comprises the following steps:

[0083] Step A1: Mix and stir tetrabutyl titanate, acetic acid, and absolute ethanol at a volume ratio of 10:2:14 to prepare solution A, and then add cerium nitrate in a doping amount of 0.5wt% until the volum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com