Electrocatalytic acetylene hydrogenation reaction method

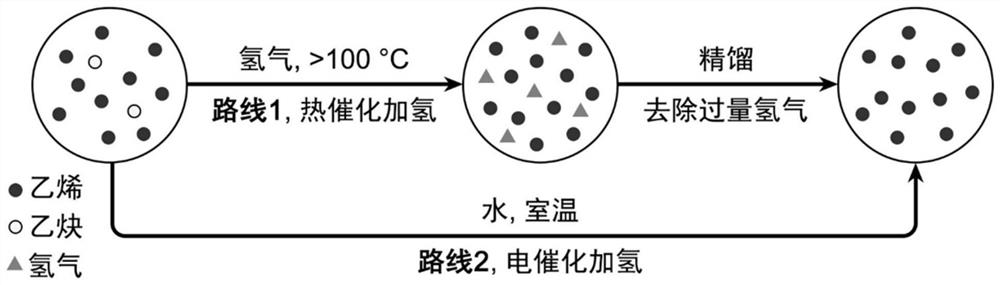

An acetylene hydrogenation and electrocatalysis technology, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of conversion rate and product selectivity gap, achieve high conversion rate, promote green sustainable development, and high selectivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0196] EAR performance of embodiment 1 LD-Cu

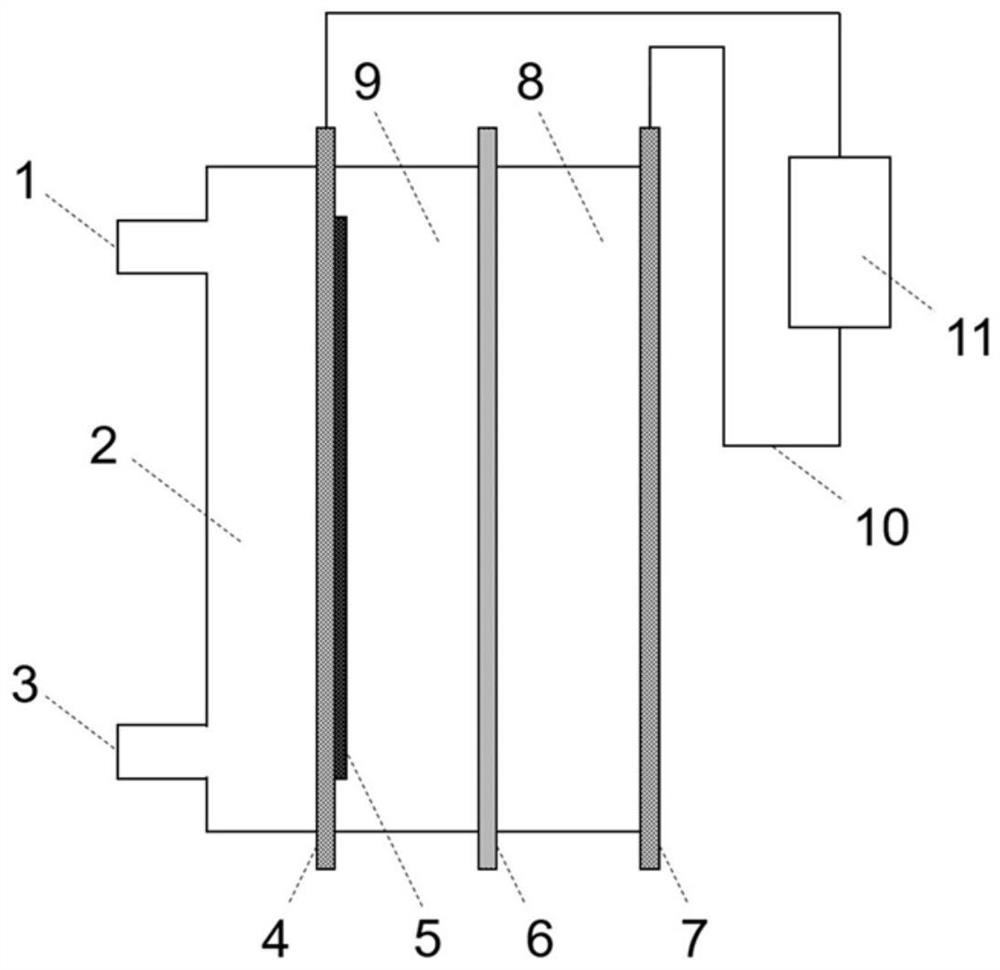

[0197] The working electrode is the gas diffusion electrode loaded with CuAl-LDH nanosheets prepared in the preparation example, the carbon cloth is used as the anode, and the gas chamber is 0.5 cm 2 The circular plane air chamber of the above-mentioned construction reaction system ( Figure 3-1 ), the power was turned on, and CuAl-LDH electroreduction was immediately performed in 1M KOH at −0.4 V for 10 min to prepare a gas-diffusion electrode loaded with LDH-derived copper catalyst (LD-Cu) (Table S1), followed by The gas inlet injects the raw material gas into the acetylene chamber; the power supply is continuously connected to make the electrochemical device work and undergo an electrolysis reaction, so that the acetylene-containing gas diffused to the working electrode undergoes an electrocatalytic hydrogenation reaction of acetylene, reducing acetylene to ethylene , the product is discharged from the gas outlet. During th...

Embodiment 2

[0204] Example 2 Cu EAR performance of NPs

[0205]Except using the gas diffusion electrode loaded with commercial Cu NPs (99.9% metal content, 10–30 nm, Shanghai Macklin Biochemical Co., Ltd.) prepared in the preparation example above, electrocatalysis was performed in a similar manner to Example 1. Hydrogenation reaction process: inject raw material gas into the acetylene gas chamber from the air inlet; turn on the power supply to make the electrochemical device work and undergo electrolysis reaction, so that the acetylene-containing gas diffused to the working electrode undergoes electrocatalytic acetylene hydrogenation reaction, The acetylene is reduced to ethylene, and the product is discharged from the gas outlet. Thus, the LSV curves and potential-dependent EAR performance of commercial metallic copper nanoparticles catalysts (Cu NPs) and the SEM images of Cu NPs on GDL before and after electrochemical reactions were tested, as shown in Figure 8 and 9 shown. The...

Embodiment 3

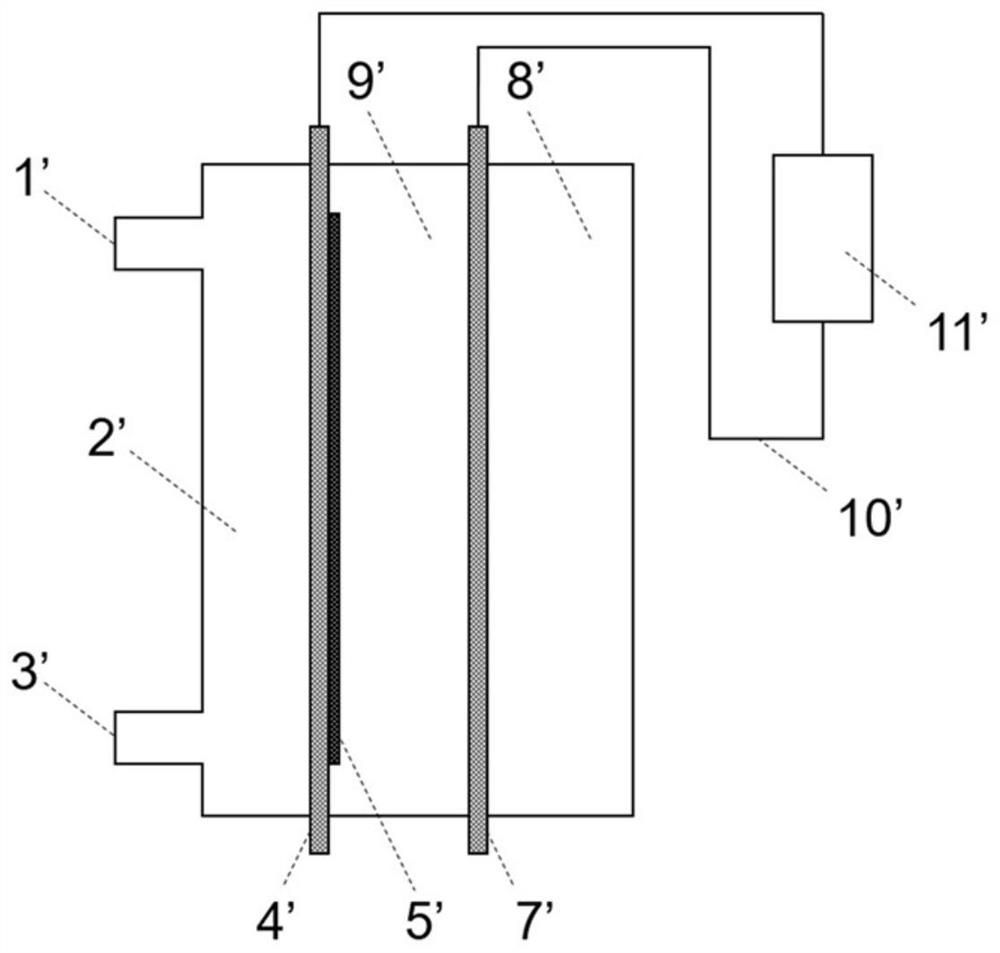

[0207] Example 3 EAR performance on LD-Cu in the presence of ethylene

[0208] In addition to using an ethylene-rich gas source (0.5% C 2 h 2 , 20%C 2 h 4 and Ar balance gas) and changing the flow rate and the structure of the gas chamber as needed, and tested at room temperature (20° C.) in a manner similar to that of Example 1. The amount of hydrogen in the outlet stream was also monitored to demonstrate the hydrogen-free nature of the EAR process. Due to the presence of large amounts of ethylene in the feed gas, removal of H 2 In addition, the production selectivity of ethylene is calculated on a carbon basis.

[0209] for 0.5cm 2 the flat air chamber, Figure 10 Panel A in , shows the conversion of acetylene at different feed gas flow rates. Adjusted by cathode potential, at 1mL min -1 A flow rate of 10000 can convert more than 98% of acetylene, with the best conversion observed at a potential of -0.4V to -0.5V. Higher flow rates resulted in lower conversion of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com