Passivation process method for gallium nitride and gallium nitride ternary alloy

A gallium nitride III technology, which is applied in electrical components, sustainable manufacturing/processing, climate sustainability, etc., can solve problems such as many surface defects and large leakage current, and achieve improved device performance and operability. Strong, simple effect of passivation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Using the present invention to passivate the silicon substrate PIN structure indium gallium nitride ultraviolet detector, the specific process steps are as follows:

[0019] (1) Epitaxially grow buffer layer, n-type gallium nitride, i-type indium gallium nitride, and p-type gallium nitride sequentially on the silicon substrate;

[0020] (2) Perform photolithography on the device to form a mesa structure, and grow p-electrodes and n-electrodes;

[0021] (3) Preferably, the device is immersed in passivation solution A or passivation solution B for passivation, passivation solution A is a mixed solution of ruthenium chloride of 0.01mol / L and nitric acid of 0.1g / L, passivation Solution B is a mixed solution of 0.01mol / L sodium sulfide and 0.1g / L nitric acid, the passivation temperature is 20°C, and the passivation time is 10min. After taking it out, wash it with deionized water and dry it with nitrogen;

[0022] (4) Preferably, a passivation layer of silicon dioxide or sil...

Embodiment 2

[0026] The specific process steps of this embodiment are similar to those of Embodiment 1, but the passivation temperature in step (3) and step (5) is adjusted to 30°C.

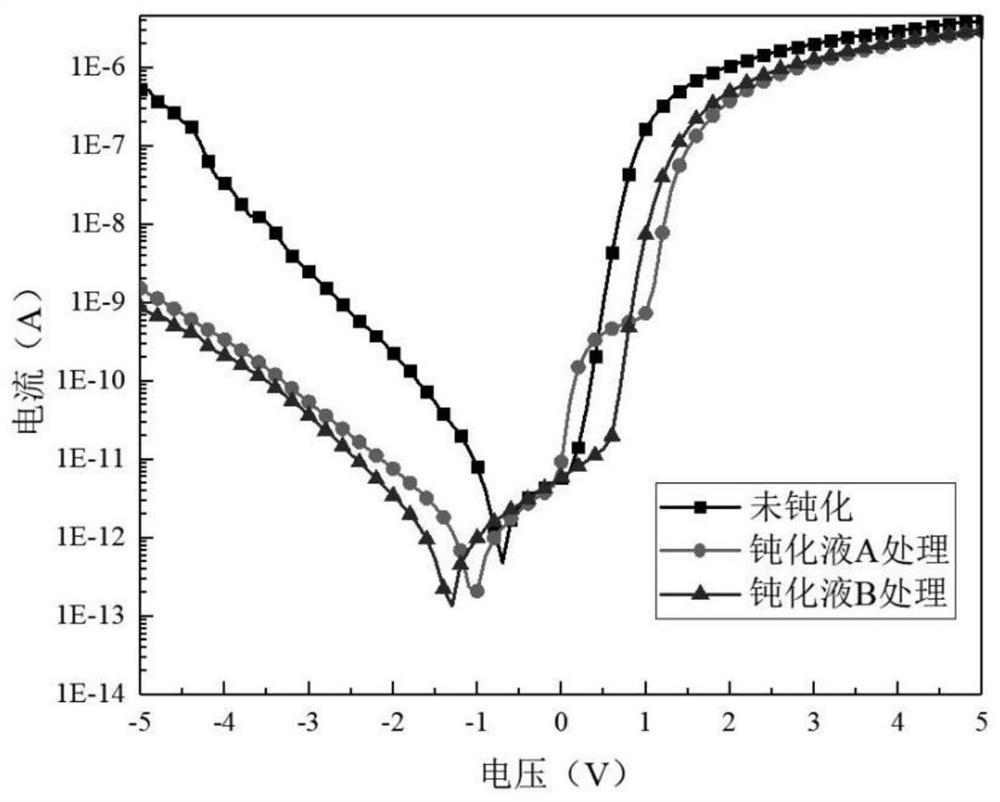

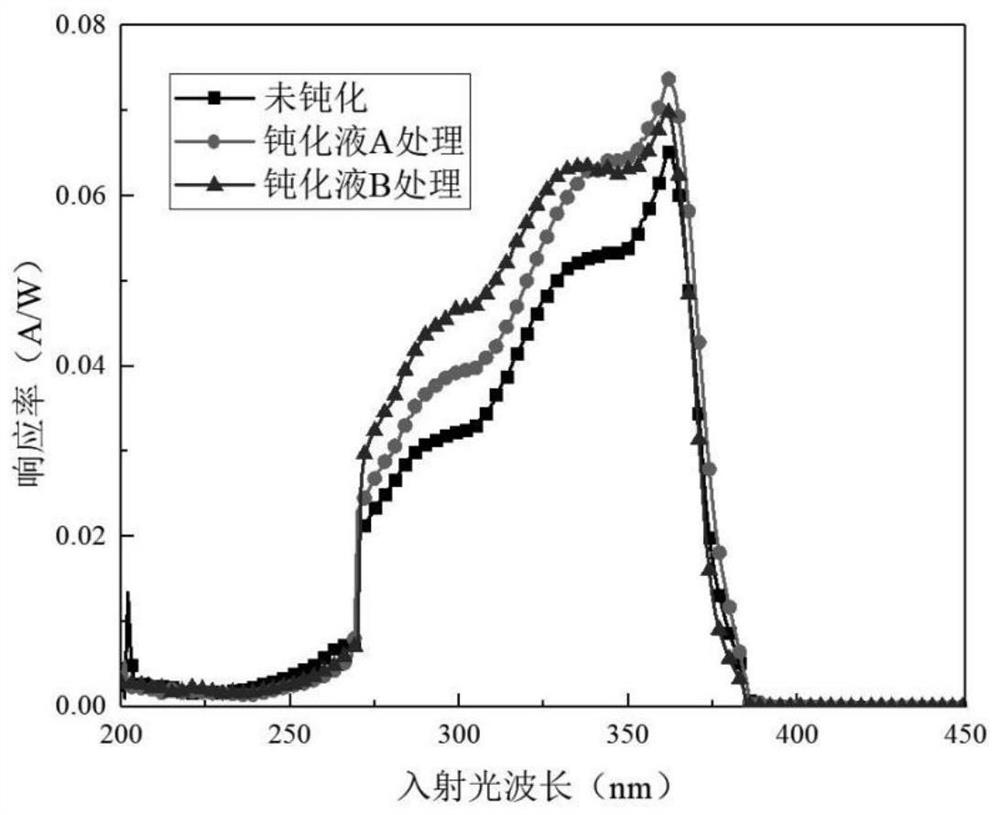

[0027] image 3 is the volt-ampere characteristic curve of the device under different passivation conditions. Compared with the devices without solution passivation, the reverse dark current of the devices treated with passivation solution A and passivation solution B decreased by 2-4 orders of magnitude. Figure 4 is the spectral responsivity curve of the device under different passivation conditions. Compared with the devices without solution passivation, the responsivity of the devices treated with passivation solution A and passivation solution B was significantly improved, and the peak responsivity increased by 15% and 25%, respectively.

Embodiment 3

[0029] The specific process steps of this embodiment are similar to those of Embodiment 1, but the passivation temperature in step (3) and step (5) is adjusted to 40°C.

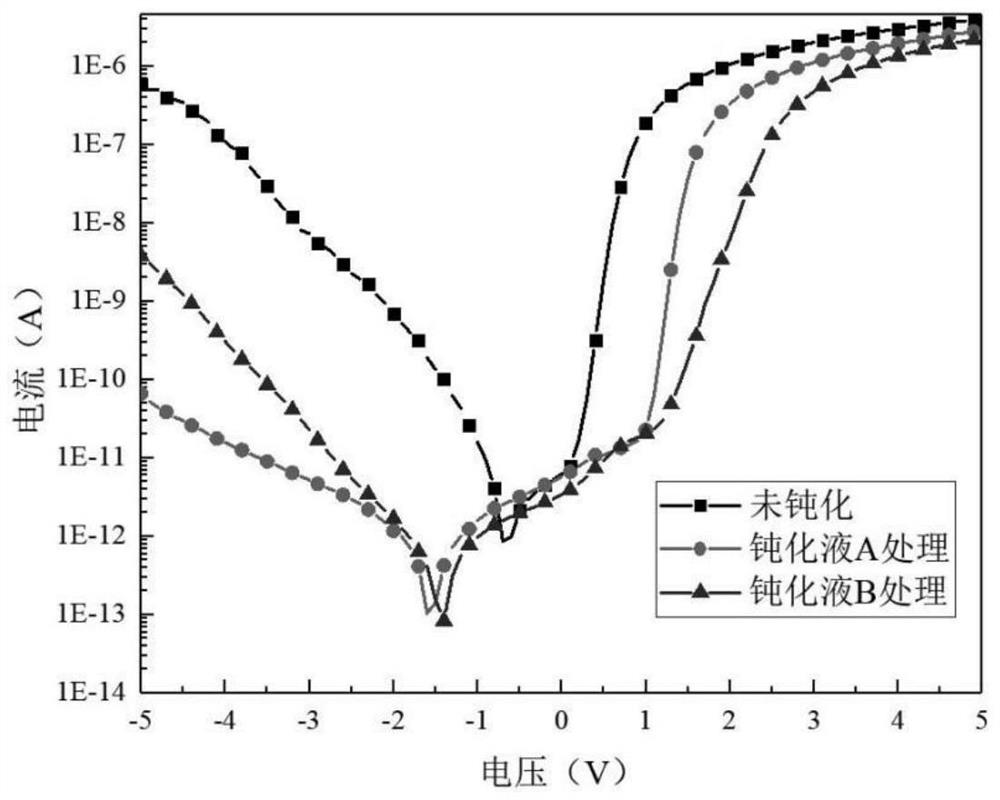

[0030] Figure 5 is the volt-ampere characteristic curve of the device under different passivation conditions. Compared with the devices without solution passivation, the reverse dark current of the devices treated with passivation solution A and passivation solution B decreased by 1-2 orders of magnitude. Figure 6 is the spectral responsivity curve of the device under different passivation conditions. Compared with the device without solution passivation, the responsivity of the device treated with passivation solution A and passivation solution B was significantly improved, and the peak responsivity increased by 1% and 10%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com