Purification method of ciprofloxacin hydrochloride, ciprofloxacin hydrochloride freeze-dried powder for injection and preparation method of ciprofloxacin hydrochloride freeze-dried powder

A technology of ciprofloxacin hydrochloride and a purification method, which is applied in the directions of medical preparations without active ingredients, medical preparations containing active ingredients, and freeze-dried transportation, can solve the problem of high impurity content of related substances and pH differences in the gastrointestinal tract. It can reduce the content of impurities, reduce the content of impurities and improve the purification yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

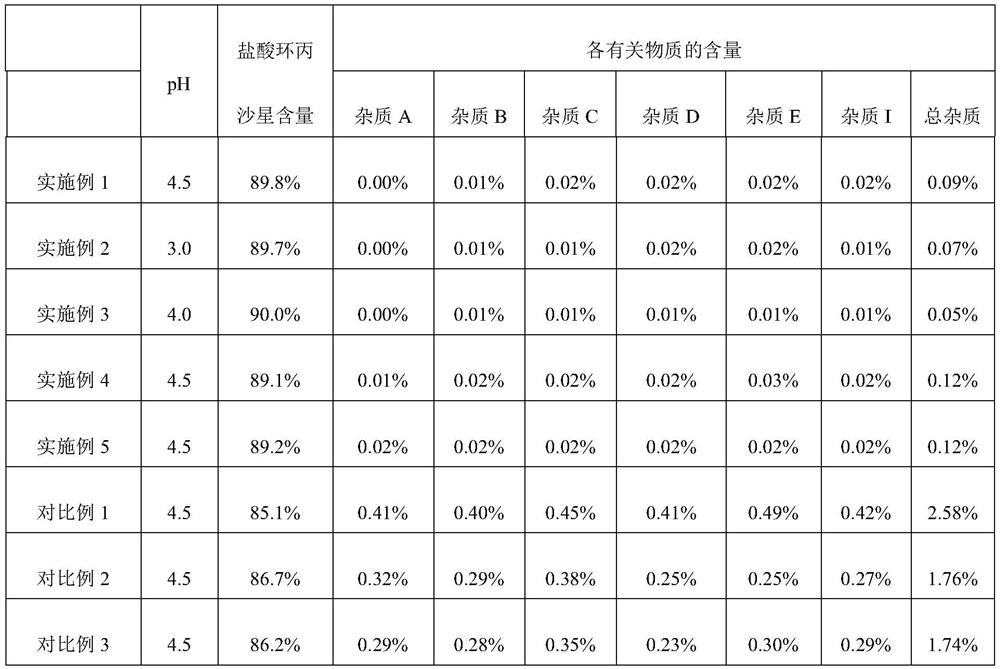

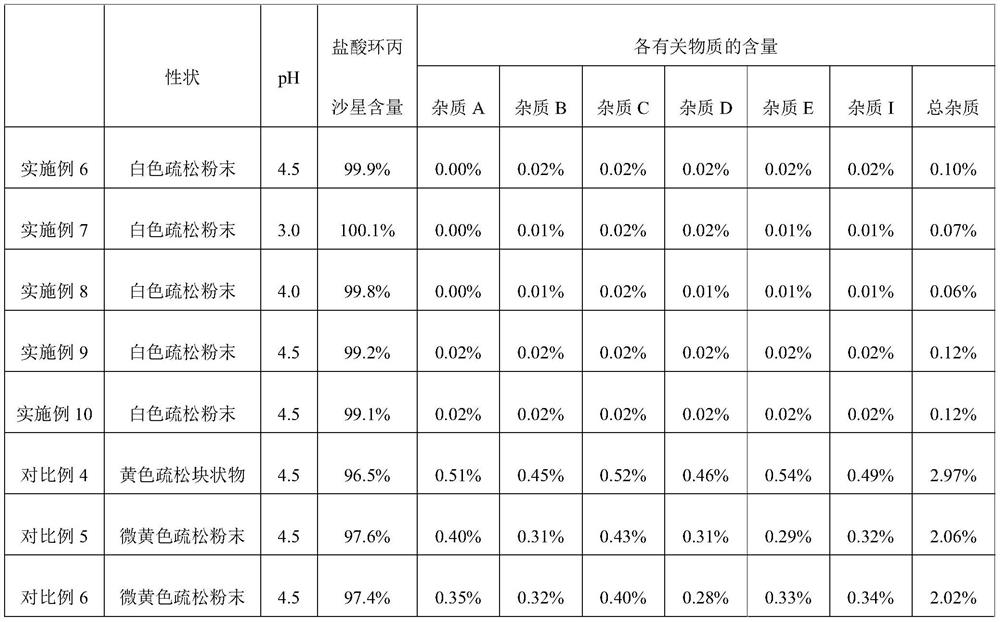

Embodiment 1

[0034] The present embodiment provides a kind of purification method of ciprofloxacin hydrochloride, specifically comprises the following steps:

[0035] Take 1.5kg of crude ciprofloxacin hydrochloride and place it in a 10L flask, add 6.0L of ethanol solution with a volume fraction of 70%, heat to 60°C and stir to dissolve, then add 7.0g of activated carbon, keep heating at 60°C for 25min, filter while hot, and the filtrate Use 30% hydrochloric acid solution to adjust the pH to 4.5, then cool to room temperature, crystallize, filter under reduced pressure to obtain white crystals, dry the white crystals at 65°C for 4 hours under reduced pressure, and obtain 1.30 kg of white crystalline powder Ciprofloxacin hydrochloride .

Embodiment 2

[0037] The present embodiment provides a kind of purification method of ciprofloxacin hydrochloride, specifically comprises the following steps:

[0038] Take 1.5kg of the crude product of ciprofloxacin hydrochloride and place it in a 10L flask, add 5.5L of ethanol solution with a volume fraction of 68%, heat to 62°C and stir to dissolve, then add 7.5g of activated carbon, keep heating at 58°C for 26min, filter while hot, and the filtrate Use 30% hydrochloric acid solution to adjust the pH to 3.0, then cool to room temperature, crystallize, filter under reduced pressure to obtain white crystals, dry the white crystals at 60°C for 4.5 hours under reduced pressure to obtain white crystalline powder Ciprofloxacin Hydrochloride 1.25 kg.

Embodiment 3

[0040] The present embodiment provides a kind of purification method of ciprofloxacin hydrochloride, specifically comprises the following steps:

[0041]Take 1.5 kg of crude ciprofloxacin hydrochloride and place it in a 10L flask, add 6.4L of ethanol solution with a volume fraction of 72%, heat to 58°C and stir to dissolve, then add 6g of activated carbon, keep heating at 62°C for 24min, filter while hot, and use the filtrate Adjust the pH to 4.0 with 30% hydrochloric acid solution, then cool to room temperature, crystallize, filter under reduced pressure to obtain white crystals, dry the white crystals at 62°C for 4.5 hours under reduced pressure to obtain 1.20 kg of white crystalline powder Ciprofloxacin hydrochloride .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com