Method for jointly preparing dicyclopentadiene dioxide and alkylene oxide by adopting titanium silicalite molecular sieve catalyst

A technology of dicyclopentadiene dioxide and titanium-silicon molecular sieves, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to solve the problem of organic peroxide separation, high product selectivity, and simple process operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of the modified Ti-HMS molecular sieve catalyst of embodiment 1

[0044] 500 ml reaction kettle, under room temperature and stirring conditions, put into 25 grams of hexadecylamine, 45 ml of water and 250 ml of ethanol successively, stir; Add diethyl silicate to the above solution and stir for 60 minutes; add 14.2 grams of tetraethyl titanate, stir and crystallize for 10 hours; add 74.9 grams of nano-carbon fibers, and continue stirring for 10 to 72 hours. After heating up, the material in the reaction kettle was crystallized at 200°C for 4 days, and then filtered to obtain a solid, which was extracted with ethanol to remove the template agent in the catalyst, and then washed with pure water until the eluent was neutral. Dry the washed solid at 110°C for 12 hours to obtain Ti-HMS supported by carbon nanofibers;

[0045] Add 300 milliliters of pure water, 3.0 grams of magnesium aluminum hydrotalcite (Mg 6 al 2 (OH) 16 CO 3 .4H 2 (0), room temperatur...

Embodiment 2~8

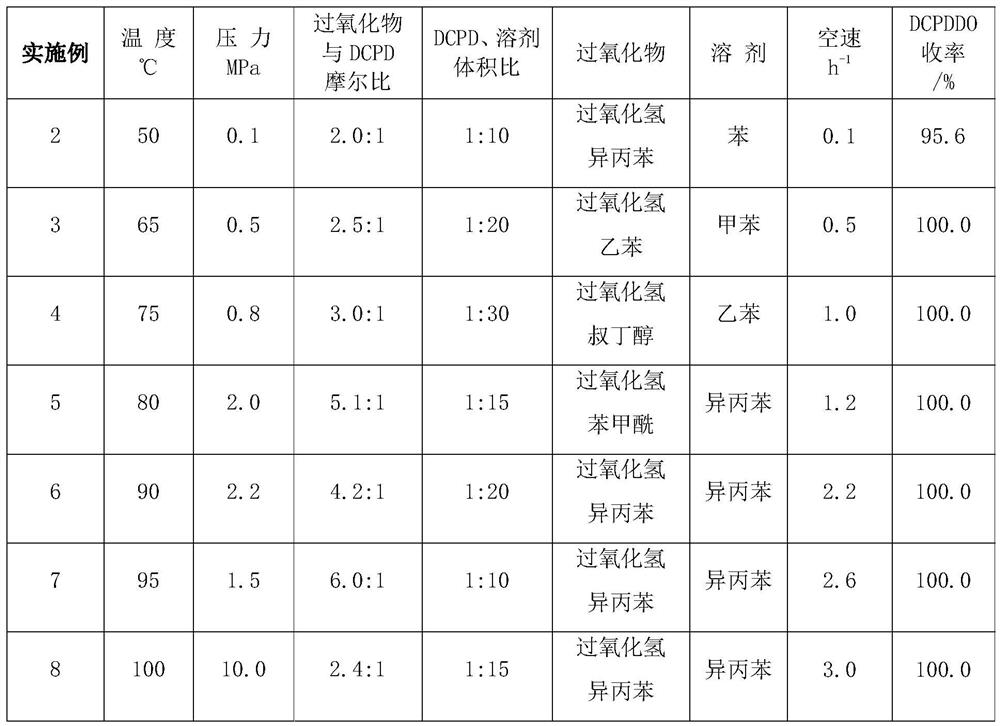

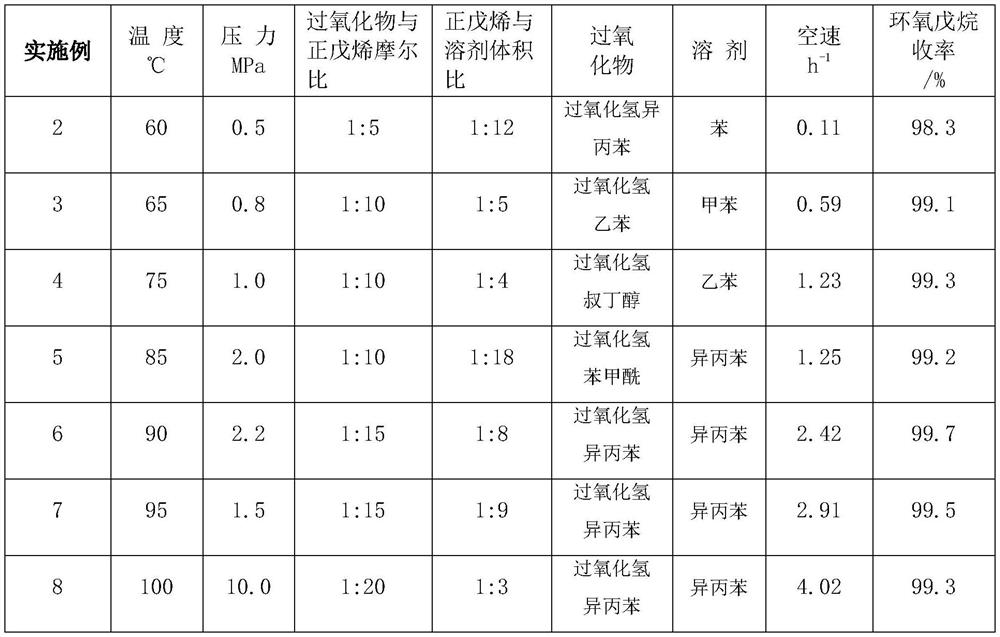

[0047] Embodiment 2~8 DCPDDO, 1,2-epoxypentane, the synthesis of 2,3-epoxypentane

[0048] 20 grams of the catalyst prepared in Example 1 were respectively packed into two 100 ml double-isothermal bed fixed-bed reactors in series, and the reaction feed liquid was pumped into the reactors through a metering pump. Using a continuous reaction process with two reactors in series, the effects of temperature, pressure, material ratio and space velocity on the reaction yield of DCPDDO, 1,2-epoxypentane or 2,3-epoxypentane were investigated. The first-stage reactor synthesizes dicyclopentadiene dioxide, and the second-stage reactor reacts excess organic peroxide with 1-pentene or 2-pentene to generate 1,2-epoxypentane or 2,3 -Pentene oxide, the used olefin raw material of the two-stage reaction of embodiment 2~5 is 1-pentene, and the used olefin raw material of embodiment 6~8 two-stage reaction is 2-pentene, and the results are shown in Table 1,2.

[0049] Table 1 One stage reaction ...

Embodiment 9~15

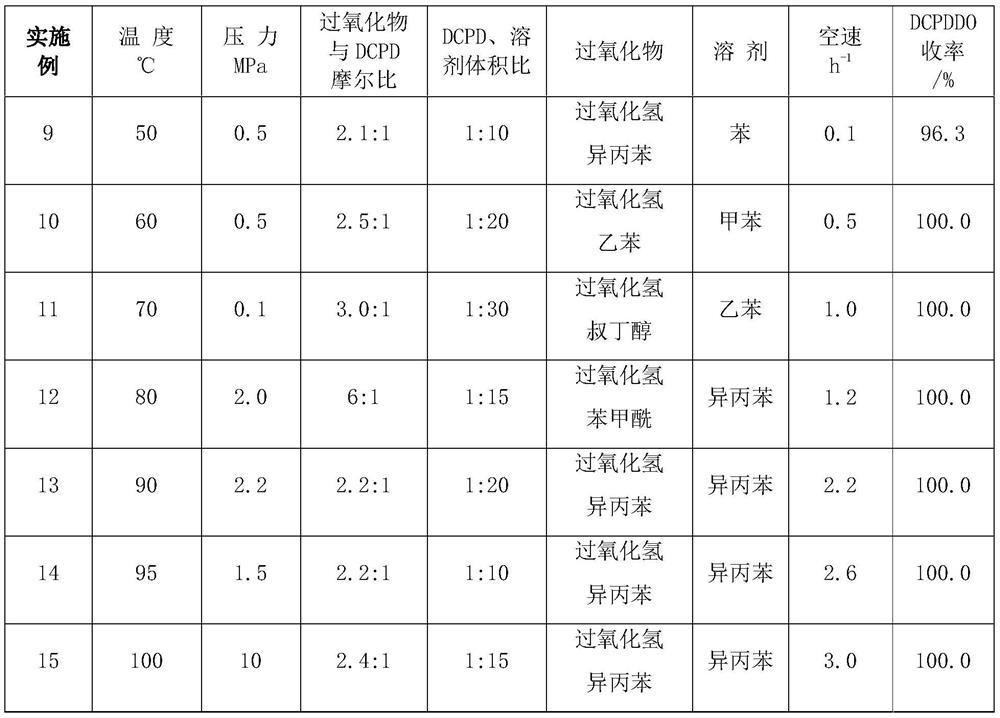

[0053] The synthesis of embodiment 9~15 DCPDDO, epoxycyclopentane

[0054] 20 grams of the catalyst prepared in Example 1 were packed into two 50 milliliter double isothermal-bed fixed-bed reactors respectively, and the reaction feed liquid was sent into the reactor by a metering pump, and a two-stage continuous reaction process was adopted to examine the temperature and pressure. , material ratio, space velocity on the reaction product DCPDDO, epoxy cyclopentane reaction yield. The first-stage reactor synthesizes dicyclopentadiene dioxide, and the second-stage reactor reacts excess organic peroxide and cyclopentene in the first-stage reactor to generate epoxycyclopentane. The results are shown in Tables 3 and 4.

[0055] Table 3 one stage reaction process

[0056]

[0057] Table 4 two-stage reaction process

[0058]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com