Preparation method of low-resistance high-transparency conductive film

A transparent conductive film, low-resistance technology, used in cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, conductive layers on insulating carriers, etc. Process application and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

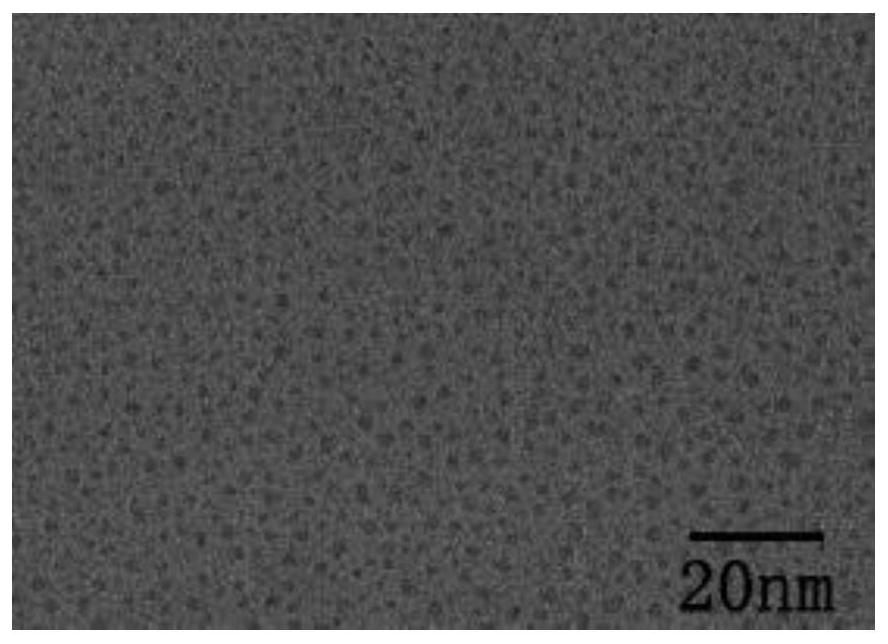

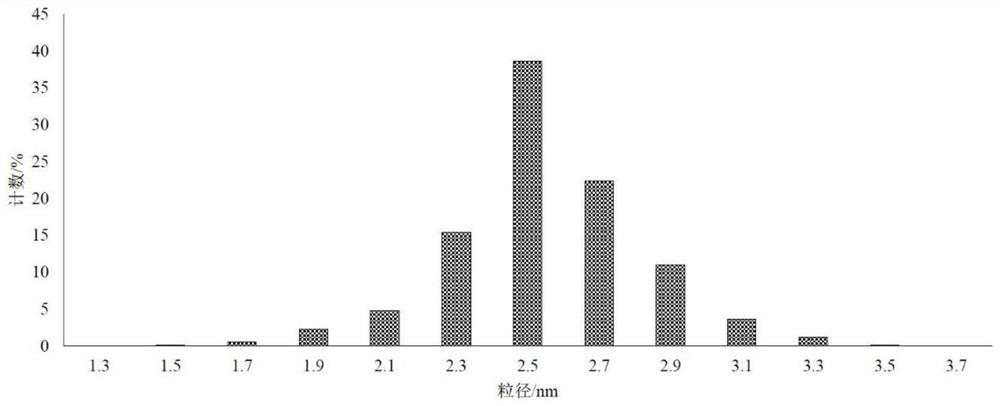

Image

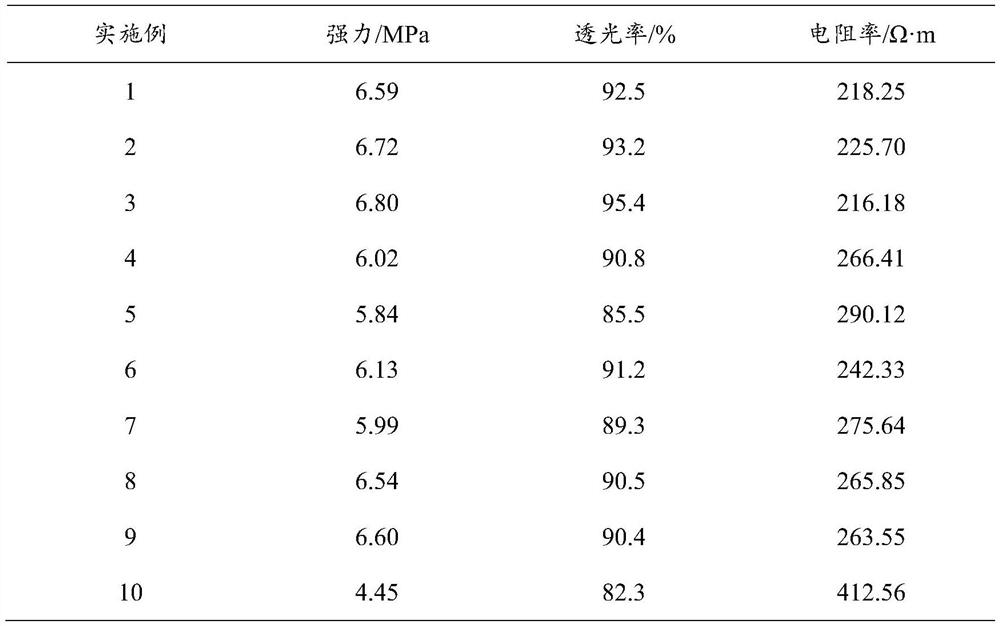

Examples

Embodiment 1

[0052] Embodiment 1: A kind of low resistance high transparent conductive film:

[0053] This embodiment provides a low-resistance and high-transparency conductive film, which is specifically prepared by the following method:

[0054] 1): 5g dry hemicellulose (weight average molecular weight 25000, dispersion coefficient 1.2) is dispersed in 200mL50 ℃ deionized water, add 15g2% sodium hydroxide solution for constant temperature alkalinization reaction for 10min; then add 5g sodium chloroacetate and heat up to At 68°C, add 25g of 2% sodium hydroxide solution for constant temperature etherification reaction for 75 minutes, neutralize the reaction system with 2% acetic acid solution to neutrality, wash with absolute ethanol, and then freeze-dry for 7 days to obtain carboxymethyl hemicellulose ;

[0055] 2): Prepare graphene dispersion, add urea according to the weight ratio of graphene and urea 1:5, completely dissolve and react with hydrothermal reaction at 160°C for 12h, take ...

Embodiment 2

[0059] Embodiment 2: A kind of low resistance high transparent conductive film:

[0060] This embodiment provides a low-resistance and high-transparency conductive film, which is specifically prepared by the following method:

[0061] 1): 5g dry hemicellulose (weight average molecular weight 27000, dispersion coefficient 1.5) is dispersed in 200mL60 ℃ deionized water, add 25g 2% sodium hydroxide solution for constant temperature alkalinization reaction for 20min; then add 10g sodium chloroacetate and heat up to Add 40g of 2% sodium hydroxide solution at 68°C for constant temperature etherification reaction for 90 minutes, neutralize the reaction system to neutral with 4% acetic acid solution, wash with absolute ethanol after precipitation, dialyze for 7 days, and then freeze-dry to obtain carboxymethyl hemicellulose ;

[0062] 2): Prepare graphene dispersion liquid, add urea according to the weight ratio of graphene and urea 1:10, completely dissolve and react in hydrothermal...

Embodiment 3

[0066] Embodiment 3: a kind of low resistance high transparent conductive film:

[0067] This embodiment provides a low-resistance and high-transparency conductive film, which is specifically prepared by the following method:

[0068]1): 5g of dried hemicellulose (weight average molecular weight 27000, dispersion coefficient 1.5) was dispersed in 200mL of 55°C deionized water, 20g of 1.5% sodium hydroxide solution was added for constant temperature alkalinization reaction for 15min; then 8g of sodium chloroacetate was added and Raise the temperature to 66°C, add 32g of 1.5% sodium hydroxide solution for constant temperature etherification reaction for 90 minutes, neutralize the reaction system with 3% acetic acid solution to neutrality, wash with absolute ethanol after precipitation, dialyze for 7 days, and freeze-dry to obtain carboxymethyl base hemicellulose;

[0069] 2): Prepare graphene dispersion liquid, add urea according to the weight ratio of graphene and urea 1:12, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com