Ternary positive electrode material@titanium nitride core-shell-structured composite material and preparation method thereof

A technology of cathode material and core-shell structure, which is applied in the field of cathode materials for lithium-ion batteries, can solve problems such as the inability to fully improve the overall performance of the composite, difficulty in ensuring the uniformity of the coating layer, and the impact of conductivity and ion conductivity. Achieve the effects of easy regulation of TiN content, low cost, and low battery internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

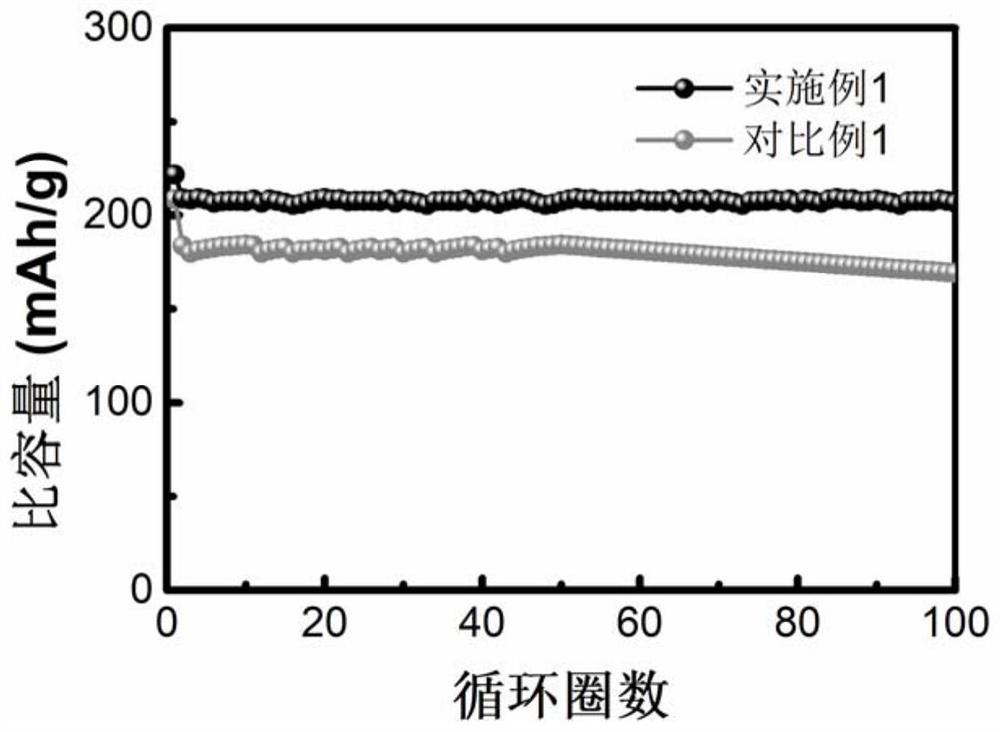

Embodiment 1

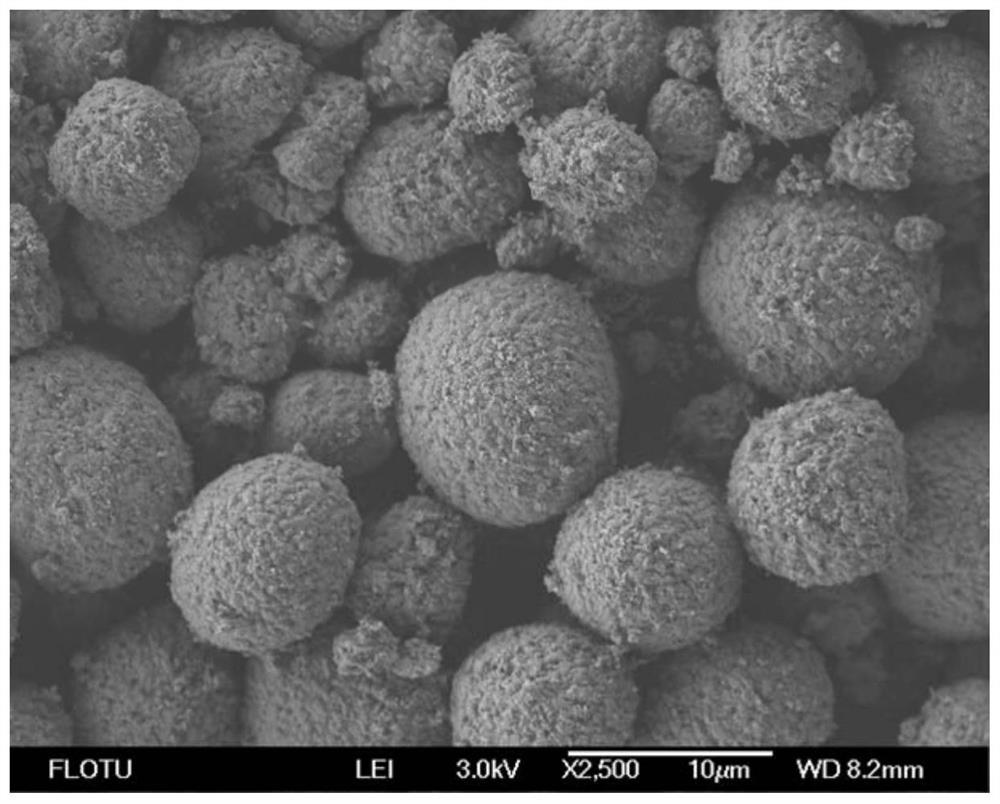

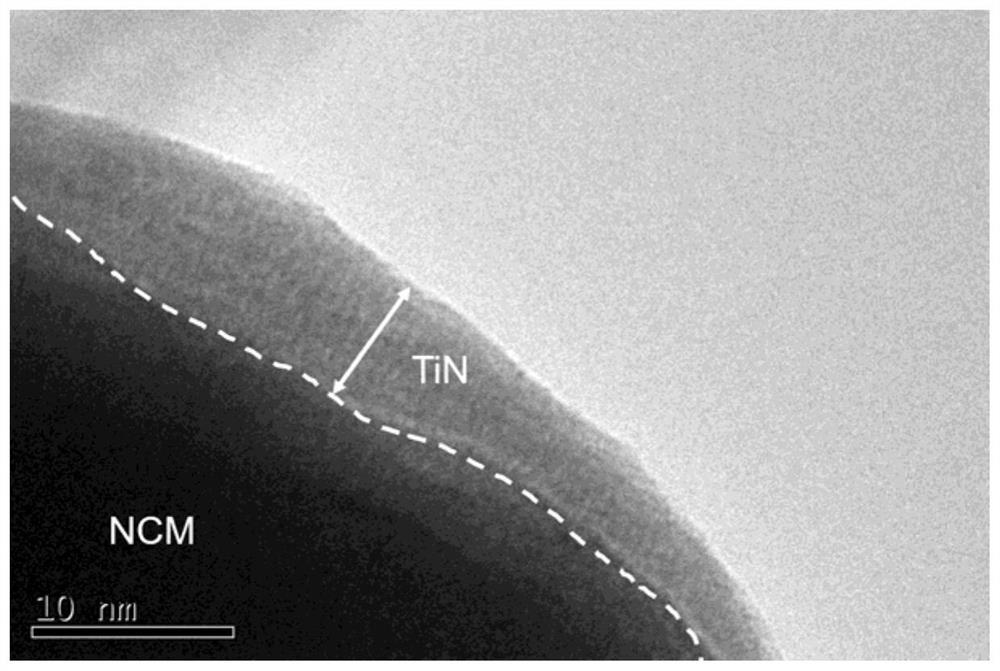

[0064] A certain amount of high-purity NCM powder is placed in a fluidized bed reactor for 500h -1 Ar gas was introduced at a space velocity of 100mL / min to keep the powder in a fully fluidized state, and then the temperature inside the reactor was raised to 900°C at 10°C / min; the TiCl carried by Ar was 4 steam and water vapor with TiCl 4 :H 2 The ratio of O=1:8, preheated to 150°C, respectively introduced into the fluidized bed for deposition reaction, in which TiCl 4 :Ar=1:7、H 2 O:Ar=1:15, the total space velocity of the two gases is 500h -1 . Stop feeding TiCl after 3h 4 Steam and water vapor, replaced by Ar and kept heating for 10min, then naturally cooled to room temperature to obtain the intermediate product NCM@TiO 2 .

[0065] The intermediate product NCM@TiO 2 Place in a fluidized bed reactor and heat until the system temperature rises to 800°C; pure N 2 The gas is introduced into the fluidized bed at 650mL / min to carry out the conversion reaction, and the in...

Embodiment 2

[0084] A certain amount of high-purity NCM powder is placed in a fluidized bed reactor for 500h -1 Ar gas was introduced at a space velocity of 300mL / min to keep the powder in a fully fluidized state, and then the temperature inside the reactor was raised to 900°C at 15°C / min; the TiCl carried by Ar was 4 steam and water vapor with TiCl 4 :H 2 The ratio of O=1:8, preheated to 200°C, respectively introduced into the fluidized bed for deposition reaction, in which TiCl 4 :Ar=1:7,H 2 O:Ar=1:15, the total space velocity of the two gases is 500h -1 . Stop feeding TiCl after 3h 4 Steam and water vapor, replaced by Ar and kept heating for 15min, then naturally cooled to room temperature to obtain the intermediate product NCM@TiO 2 .

[0085] The intermediate product NCM@TiO 2 Place in a fluidized bed reactor and heat until the system temperature rises to 800°C; pure N 2 The gas is introduced into the fluidized bed at 650mL / min to carry out the conversion reaction, and the in...

Embodiment 3

[0087] A certain amount of high-purity NCA powder is placed in the fluidized bed reactor for 800h -1 Ar gas was introduced at a space velocity of 500mL / min to keep the powder in a fully fluidized state, and then the temperature inside the reactor was raised to 1100°C; the TiCl carried by Ar was 4 steam and water vapor with TiCl 4 :H 2 The ratio of O=1:10, preheated to 300°C, respectively introduced into the fluidized bed for deposition reaction, in which TiCl 4 :Ar=1:2, H 2 O:Ar=1:30, the total space velocity of the two gases is 800h -1 . Stop feeding TiCl after 4h 4 steam and water vapor, replaced by Ar and kept heating for 30min, then naturally cooled to room temperature to obtain the intermediate product NCA@TiO 2 .

[0088] The intermediate product NCA@TiO 2 Place in a fluidized bed reactor and heat until the system temperature rises to 1000°C; pure NH 3 The gas is introduced into the fluidized bed at 800mL / min to carry out the conversion reaction, and the introdu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com