Passive battery thermal regulator, method and management system based on supercooled phase change material

A phase-change material and passive technology, applied in secondary batteries, electrochemical generators, circuits, etc., can solve problems such as non-utilization, inability to absorb heat at high temperature, and achieve the effect of maintaining charge and discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

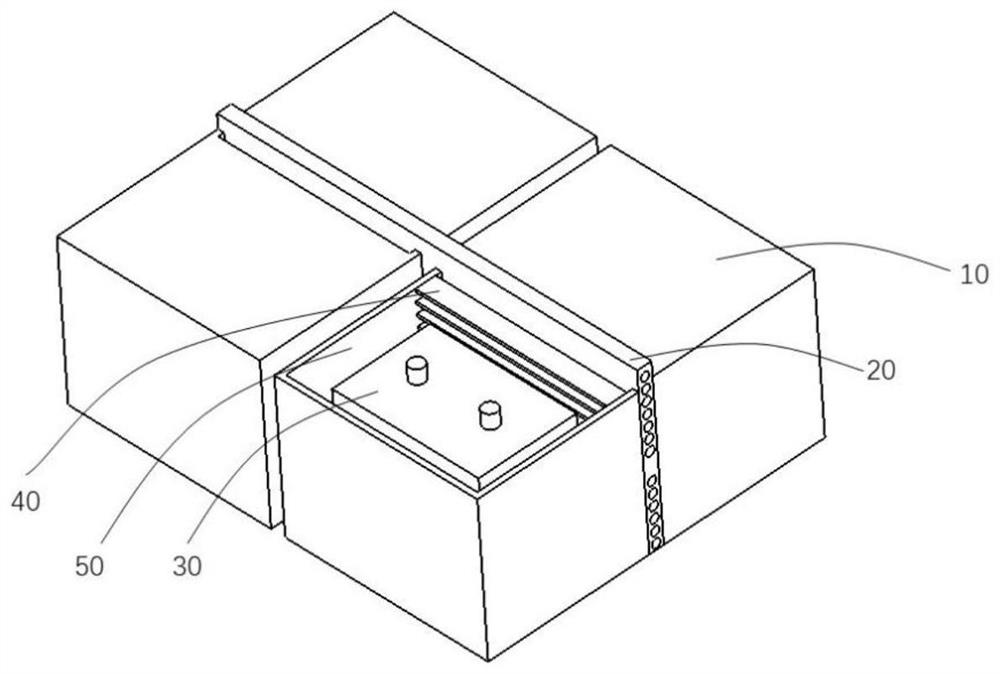

[0076] like figure 1 As shown, the embodiment of the present application provides a passive thermal regulator device, which can control the temperature of the battery pack within a reasonable temperature working range by storing and releasing the heat generated by the battery pack 30, It includes the housing 10 , the subcooled phase change module 50 , the auxiliary heat exchange device 20 and the thermal switch device 40 .

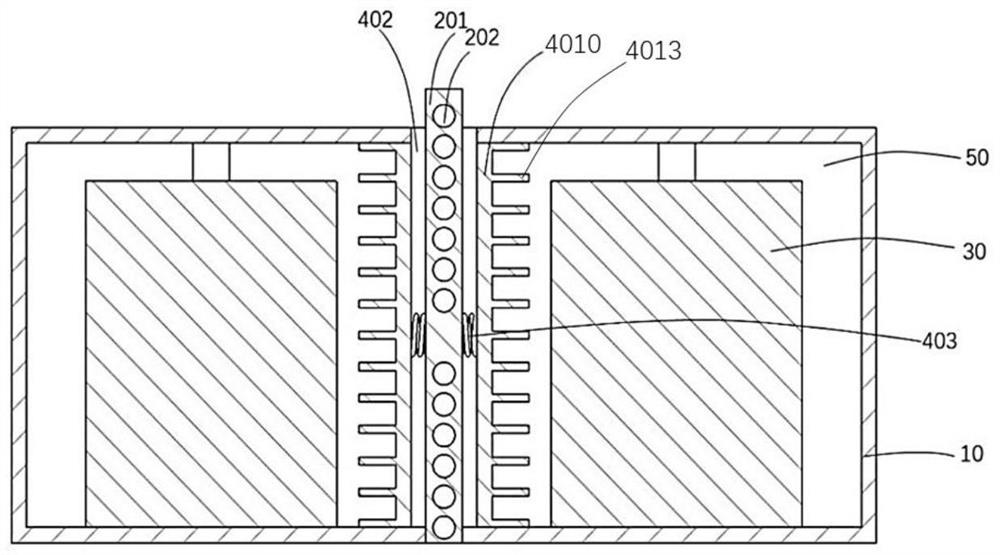

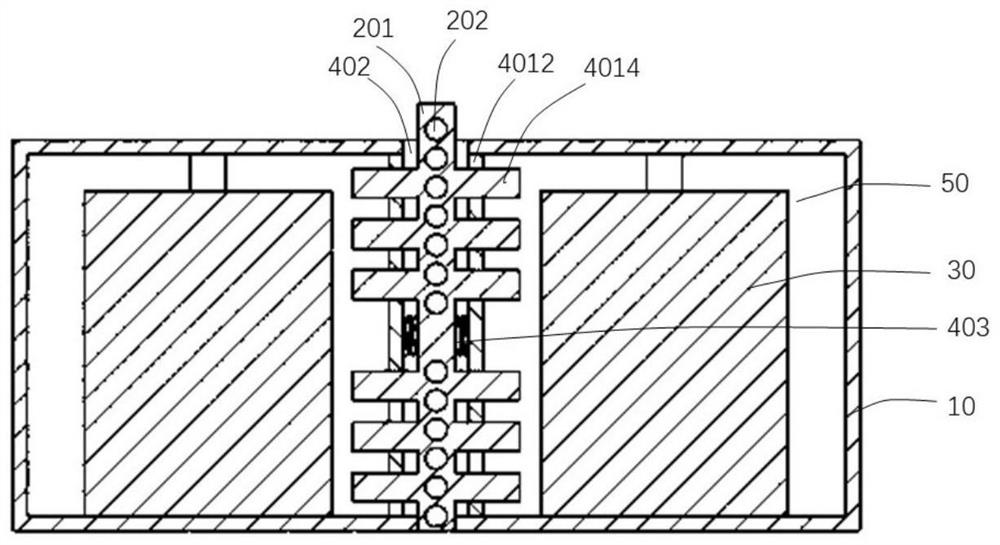

[0077] Figure 2A It is shown that when the fins 4013 are fixed on the piston body 4010, figure 1 Side view cross-sectional structure of the device shown. image 3 shown as figure 1 , Figure 2ATop sectional view of the device shown. The battery pack is provided with a battery pack casing 10 formed from a rigid casing constructed of copper or other metal with good thermal conductivity, the purpose of which is to enclose the lithium-ion battery pack and ensure mechanical support for the battery pack and its thermal conduction, while enhancing and The ...

Embodiment 2

[0089] This embodiment provides a passive thermal regulator device, the structure of which is basically the same as that of Embodiment 1, the differences are: Figure 8 As shown, the finned piston 401 in the thermal switch device 40 is changed to a non-finned piston 4011 structure. The design of the fins can increase the heat exchange area and enhance the heat exchange effect, but will reduce the space of the subcooled phase change module 50 . Changing to the piston 4011 without fins can increase the storage space of the supercooled phase change module to store more supercooled phase change modules, which can store more heat, increase the energy storage energy, and prolong the battery heating time.

Embodiment 3

[0091] This embodiment provides a passive thermal regulator device, the structure of which is basically the same as that of the second embodiment, the difference is: Figure 9As shown, the supercooled phase change module 50 is changed to a combination of multilayer phase change energy storage materials 501 . The multi-layer phase change energy storage material 501 may include: phase change materials with supercooling degree, such as sodium thiosulfate pentahydrate layer, sodium acetate trihydrate layer, lithium nitrate trihydrate layer, etc., which are helpful for different solidification-melting batteries The realization of the working temperature control range; phase change materials with large volume changes, such as unsaturated fatty acid (lauric acid) layers, etc., contribute to large changes in volume during the phase change process; phase change materials with large latent heat, such as Organic solid-liquid phase change material (paraffin) layers such as aliphatic hydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| latent heat | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com