Aluminum-plastic separating agent and aluminum-plastic separating method

A technology of aluminum-plastic separation and initiator, applied in the direction of reagents, educts, plastic recycling, etc., can solve the problems of environment and operator injury, difficult aluminum-plastic composite membrane separation, high volatility, etc., achieve less loss and promote dissolution , good permeability and surface active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

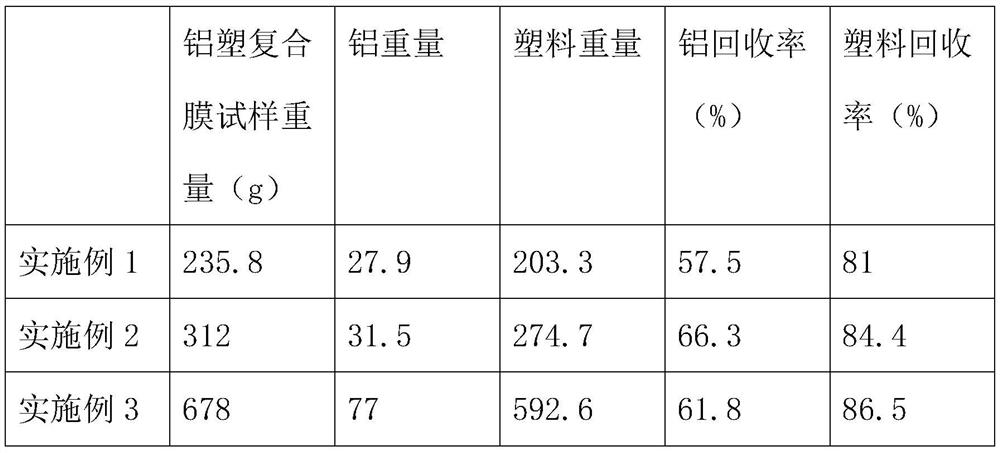

Embodiment 1

[0020] A kind of aluminum-plastic separating agent, it has included each raw material of following weight part:

[0021] Hydroxyethyl cellulose 1, formic acid 10, fatty acid diethanolamide 1, ethylenediaminetetraacetic acid 2, methyl methacrylate 20, ammonium persulfate 0.6.

[0022] The preparation method of described separating agent comprises the following steps:

[0023] (1) Get ammonium persulfate, join in the deionized water of 30 times of its weight, stir, obtain initiator solution;

[0024] (2) Mix ethylenediaminetetraacetic acid and methyl methacrylate, add it to deionized water 20 times the weight of the mixture, stir evenly, send it into the reaction kettle, feed nitrogen gas, and adjust the temperature of the reaction kettle to 75°C , dropwise adding the above-mentioned initiator solution, after the dropwise addition is completed, heat preservation and stirring for 3 hours, discharge and cool to obtain a polymer emulsion;

[0025] (3) Take ethyl cellulose, add it...

Embodiment 2

[0032] A kind of aluminum-plastic separating agent, it has included each raw material of following weight part:

[0033] Hydroxyethyl cellulose 2, formic acid 16, fatty acid diethanolamide 2, ethylenediaminetetraacetic acid 4, methyl methacrylate 30, ammonium persulfate 0.7.

[0034] The preparation method of described separating agent comprises the following steps:

[0035] (1) Get initiator, join in the deionized water of 40 times of its weight, stir, obtain initiator solution;

[0036] (2) Mix ethylenediaminetetraacetic acid and methyl methacrylate, add it to deionized water 30 times the weight of the mixture, stir evenly, send it into the reaction kettle, feed nitrogen gas, and adjust the temperature of the reaction kettle to 80°C , dropwise adding the above-mentioned initiator solution, after the dropwise addition is completed, heat preservation and stirring for 4 hours, discharge and cool to obtain a polymer emulsion;

[0037] (3) Take ethyl cellulose, add it to 70 tim...

Embodiment 3

[0044] A kind of aluminum-plastic separating agent, it has included each raw material of following weight part:

[0045] Hydroxyethyl cellulose 1, formic acid 14, fatty acid diethanolamide 2, ethylenediaminetetraacetic acid 3, methyl methacrylate 25, ammonium persulfate 0.6.

[0046] The preparation method of described separating agent comprises the following steps:

[0047] (1) Get initiator, join in the deionized water of 36 times of its weight, stir, obtain initiator solution;

[0048] (2) Mix ethylenediaminetetraacetic acid and methyl methacrylate, add it to deionized water 25 times the weight of the mixture, stir evenly, send it into the reaction kettle, feed nitrogen gas, and adjust the temperature of the reaction kettle to 77°C , dropwise adding the above-mentioned initiator solution, after the dropwise addition is completed, heat preservation and stirring for 3 hours, discharge and cool to obtain a polymer emulsion;

[0049] (3) Take ethyl cellulose, add it to 65 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com