Bone tissue engineering scaffold material and preparation method thereof

A technology of bone tissue engineering and scaffold material, which is applied in tissue regeneration, medical science, prosthesis, etc. It can solve the problems of uncontrollable degradation cycle, poor osteoinductivity and conductivity, and high preparation cost, and achieve good osteogenic effect and cost. The effect of low cost and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A preparation method for bone tissue engineering scaffold material, comprising the following steps:

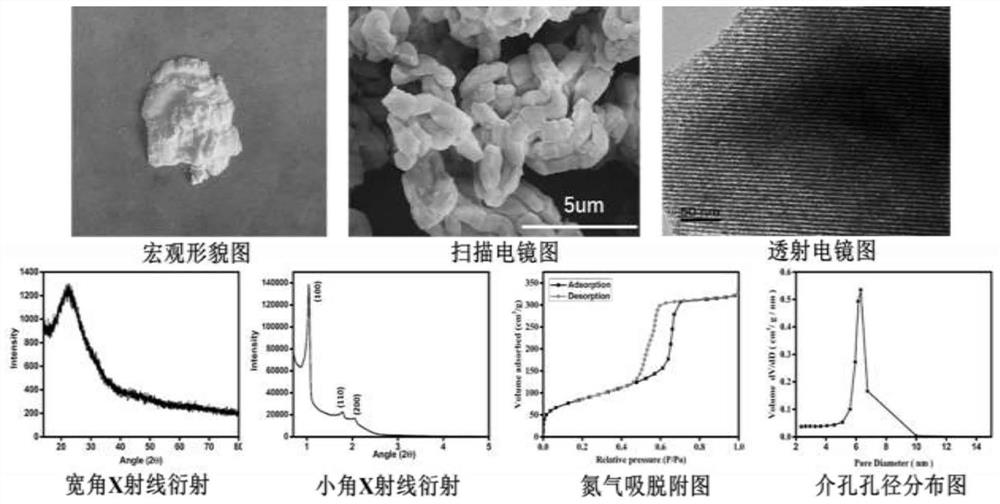

[0052] (1) Preparation of mesoporous bioactive glass powder: Weigh 60g of absolute ethanol and add it to a beaker, then weigh 1ml of 0.5mol / L hydrochloric acid and add it to absolute ethanol, then weigh 4.0g of P123 and add it to absolute ethanol, Stir at room temperature until P123 is completely dissolved; then weigh 1.4g Ca(NO 3 ) 2 4H 2 Slowly add O into the solution, stirring while adding, until it is completely dissolved; then measure 0.69ml TEP and slowly drop it into the solution at a rate of 15 drops / min. After adding TEP, measure 7.3ml TEOS and slowly drop it into the solution In the process, the dropping rate was 15 drops / min. After all the additions were completed, the sol solution was obtained by continuous stirring at room temperature for 36 hours; The rubber is placed in a high-temperature calcining box furnace with a heating rate of 1°C / min. When the t...

Embodiment 2

[0056] A preparation method for bone tissue engineering scaffold material, comprising the following steps:

[0057] (1) Preparation of mesoporous bioactive glass powder: Weigh 60g of absolute ethanol and add it to a beaker, then weigh 1ml of 0.5mol / L hydrochloric acid and add it to absolute ethanol, then weigh 4.0g of P123 and add it to absolute ethanol, Stir at room temperature until P123 is completely dissolved; then weigh 1.4g Ca(NO 3 ) 2 4H 2 Slowly add O into the solution, stirring while adding, until it is completely dissolved; then measure 0.69ml TEP and slowly drop it into the solution at a rate of 15 drops / min. After adding TEP, measure 7.3ml TEOS and slowly drop it into the solution In the process, the dropping rate was 15 drops / min. After all the additions were completed, the sol solution was obtained by continuous stirring at room temperature for 36 hours; The rubber is placed in a high-temperature calcining box-type furnace with a heating rate of 1°C / min. When ...

Embodiment 3

[0060] A preparation method for bone tissue engineering scaffold material, comprising the following steps:

[0061] (1) Preparation of mesoporous bioactive glass powder: Weigh 60g of absolute ethanol and add it to a beaker, then weigh 1ml of 0.5mol / L hydrochloric acid and add it to absolute ethanol, then weigh 4.0g of P123 and add it to absolute ethanol, Stir at room temperature until P123 is completely dissolved; then weigh 1.4g Ca(NO 3 ) 2 4H 2 Slowly add O into the solution, stirring while adding, until it is completely dissolved; then measure 0.69ml TEP and slowly drop it into the solution at a rate of 15 drops / min. After adding TEP, measure 7.3ml TEOS and slowly drop it into the solution In the process, the dropping rate was 15 drops / min. After all the additions were completed, the sol solution was obtained by continuous stirring at room temperature for 36 hours; The rubber is placed in a high-temperature calcining box-type furnace with a heating rate of 1°C / min. When ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com