A kind of flocculant and its preparation method and application

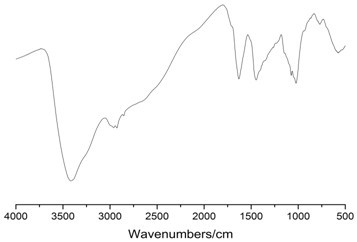

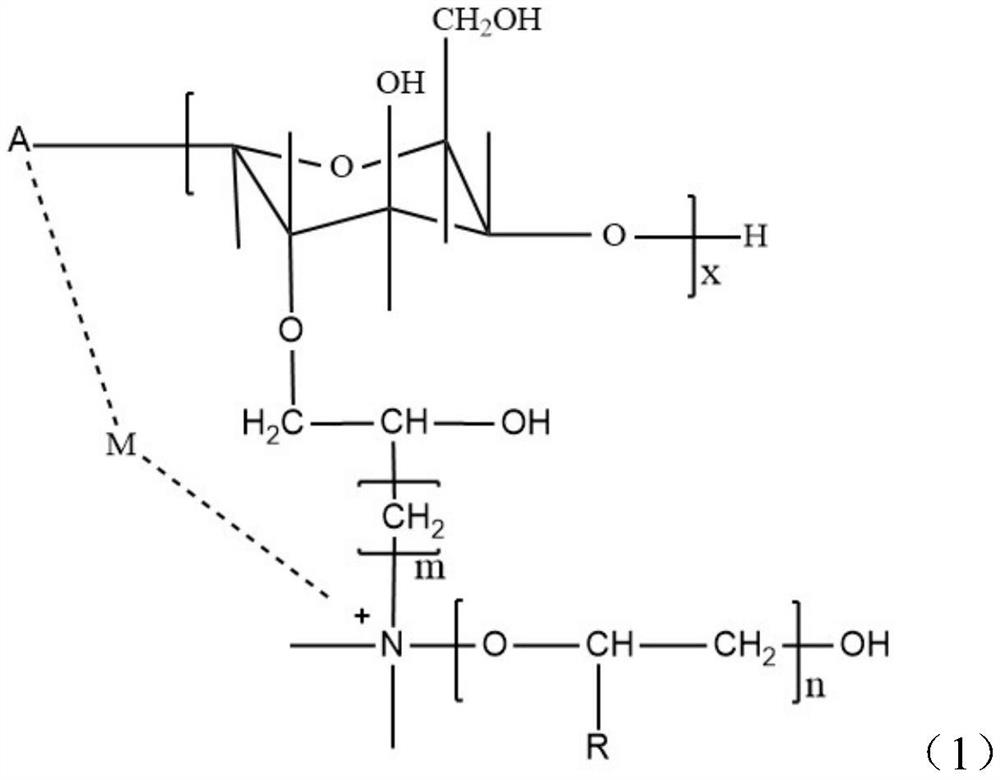

A technology of flocculant and crosslinking agent, applied in the field of flocculant and its preparation, can solve the problems of complicated operation steps, unfavorable industrialization, etc., and achieve the effects of improving flocculation efficiency, increasing cationic charge, and improving shear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Firstly, 20g of potato starch and 200g of deionized water were respectively weighed into a three-necked bottle with a stirrer, protected by nitrogen gas, and gelatinized for 40min under a constant temperature water bath at 90°C to obtain gelatinized starch.

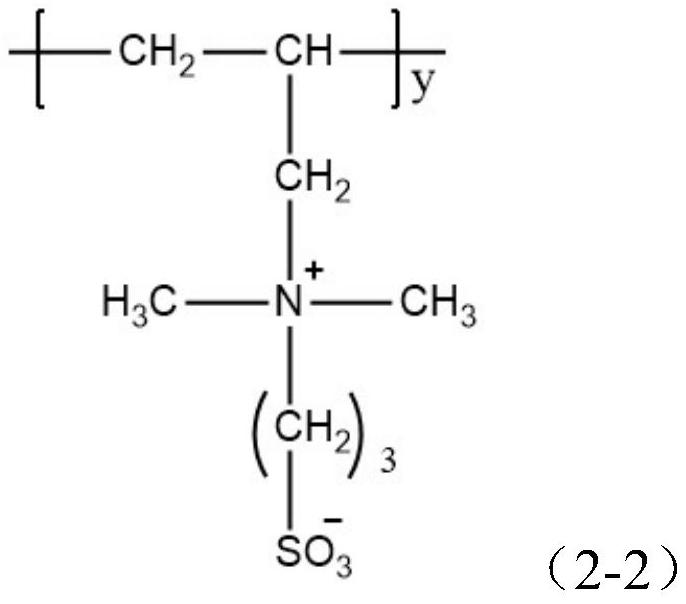

[0060] Take 10g of N-methyldiallyl propanesulfonate into a beaker, add 70g of deionized water, add sodium hydroxide to adjust the pH to 8, and magnetically stir in the beaker for 1h to obtain N-methyldiallyl Aqueous solution of propanesulfonic acid salt.

[0061] Cool the gelatinized starch in the three-necked flask to 50°C, add 0.45 g of potassium persulfate and stir for 30 minutes, then add the prepared N-methyl diallyl propane sulfonate aqueous solution, and continue stirring for 4 hours to obtain graft copolymerization. Modified starch solution.

[0062] At the same time, 10.3 g of diethylenetriamine and 8.8 g of ethylene oxide were sequentially added to a round-bottomed flask with a stirrer, and reacted for 1...

Embodiment 2

[0066] First, 10g of corn starch and 150g of deionized water were respectively weighed into a three-necked flask with a stirrer, protected by nitrogen gas, and gelatinized for 30min under a constant temperature water bath at 90°C to obtain gelatinized starch.

[0067] Take 10g of N-methyldiallyl propanesulfonate into a beaker, add 50g of deionized water, add potassium hydroxide to adjust the pH to 8, and magnetically stir in the beaker for 30min to obtain N-methyldiallyl Aqueous solution of propanesulfonic acid salt.

[0068] Cool the gelatinized starch in the three-necked flask to 50°C, add 0.15 g of potassium persulfate and stir for 5 minutes, then add the prepared N-methyl diallyl propane sulfonate aqueous solution, and continue stirring for 4 hours to obtain graft copolymerization. Modified starch solution.

[0069] At the same time, 6 g of ethylenediamine and 11.6 g of propylene oxide were sequentially added to a round-bottomed flask with a stirrer, reacted for 1 h under...

Embodiment 3

[0073] Firstly, 30g of cornstarch and 150g of deionized water were respectively weighed into a three-necked flask with a stirrer, protected by nitrogen gas, and gelatinized for 50min under a constant temperature water bath at 95°C to obtain gelatinized starch.

[0074] Take 10g of N-methyldiallyl butanesulfonate into a beaker, add 50g of deionized water, add sodium hydroxide to adjust the pH to 9, and magnetically stir in the beaker for 30min to obtain N-methyldiallyl butanesulfonate aqueous solution.

[0075] Cool the gelatinized starch in the three-necked flask to 60°C, add 0.3 g of potassium persulfate, and stir for 15 minutes, then add the prepared N-methyldiallyl butanesulfonate aqueous solution, and continue stirring for 5 hours to obtain graft copolymerization. Modified starch solution.

[0076] At the same time, 10 g of triethylenetetramine and 12 g of propylene oxide were added to a round-bottomed flask with a stirrer in turn, and the reaction was carried out under t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com