Treatment method of refined cotton sludge

A technology for refining cotton and sludge, applied in the directions of microorganism-based methods, microbial treatment, combined biological treatment, etc., can solve the resource utilization of unseen refined cotton sludge, increase the difficulty of refined cotton sludge treatment, and refine cotton sludge. The problem of high water content of mud has achieved the effect of widely popularized and utilized value, low cost and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] In the present invention, the preparation method of the Bacillus subtilis bacteria liquid and the Bacillus licheniformis bacteria liquid comprises: respectively inoculating the Bacillus subtilis and the Bacillus licheniformis in LB liquid medium, and vibrating culture to obtain corresponding bacterial liquids. In the present invention, the formula of the LB liquid culture medium is preferably 10 g of tryptone, 5 g of yeast extract, 10 g of NaCl, 1000 mL of distilled water, and pH 7.0. In the present invention, as an embodiment, the temperature of the shaking culture is preferably 35-40° C., more preferably 37° C., and the time is preferably 40-50 h, more preferably 48 h.

[0021] In the present invention, the preparation method of the Saccharomyces cerevisiae liquid preferably comprises: inoculating Saccharomyces cerevisiae on PD medium, and vibrating culture to obtain the Saccharomyces cerevisiae liquid. In the present invention, as an embodiment, the preparation metho...

Embodiment 1

[0040] Preparation of compound bacterial agent

[0041] (1) Preparation of Bacillus subtilis bacterium liquid and Bacillus licheniformis bacterium liquid

[0042] Bacillus subtilis and Bacillus licheniformis were respectively inoculated in LB liquid medium, and cultured with shaking at 37°C for 48 hours to obtain corresponding bacterial solutions. The formula of LB liquid medium is 10g of tryptone, 5g of yeast extract, 10g of NaCl, 1000mL of distilled water, pH7.0.

[0043] (2) Preparation of Saccharomyces cerevisiae liquid

[0044] Saccharomyces cerevisiae was inoculated in PD medium, and cultured with shaking at 30° C. for 48 hours to obtain the Saccharomyces cerevisiae bacterial liquid. The preparation method of the PD medium is as follows: peel and cut 200g of potatoes into small pieces, mix with 20g of glucose and 1000mL of distilled water, boil for 20 minutes, then filter with gauze, and the obtained filtrate is the PD medium.

[0045] (3) Preparation of Trichoderma v...

Embodiment 2

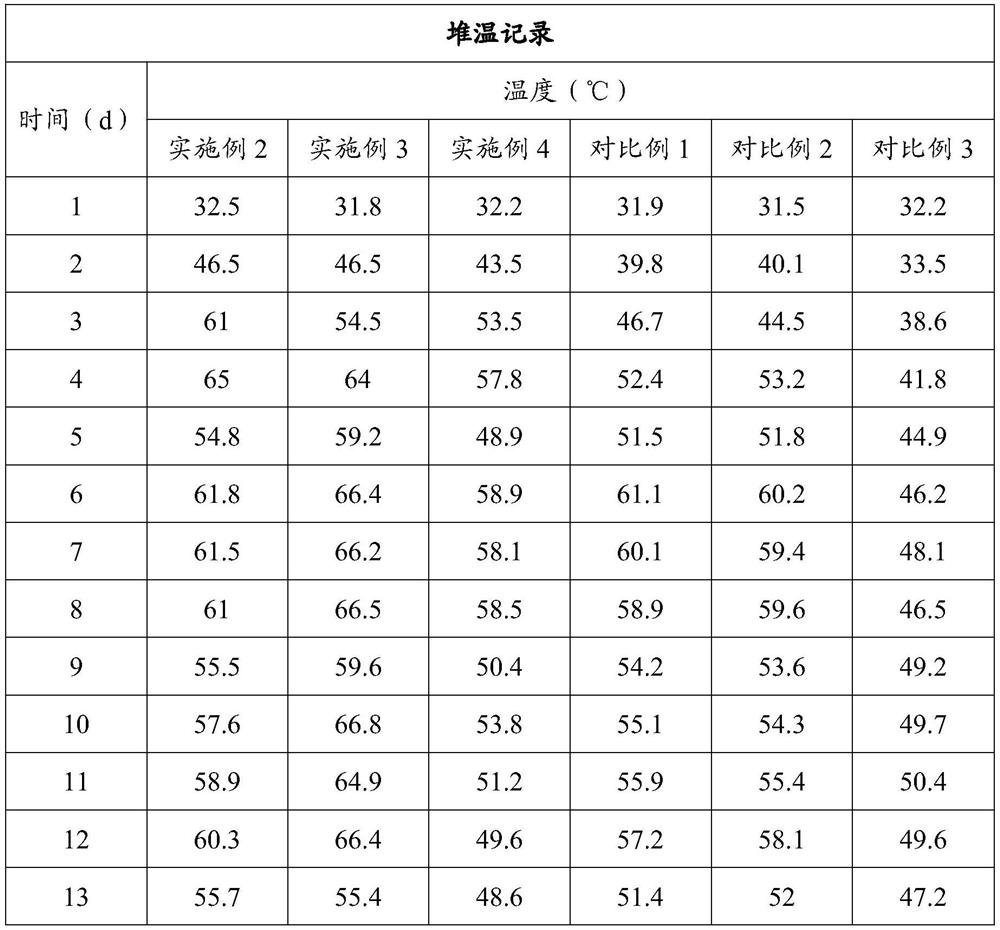

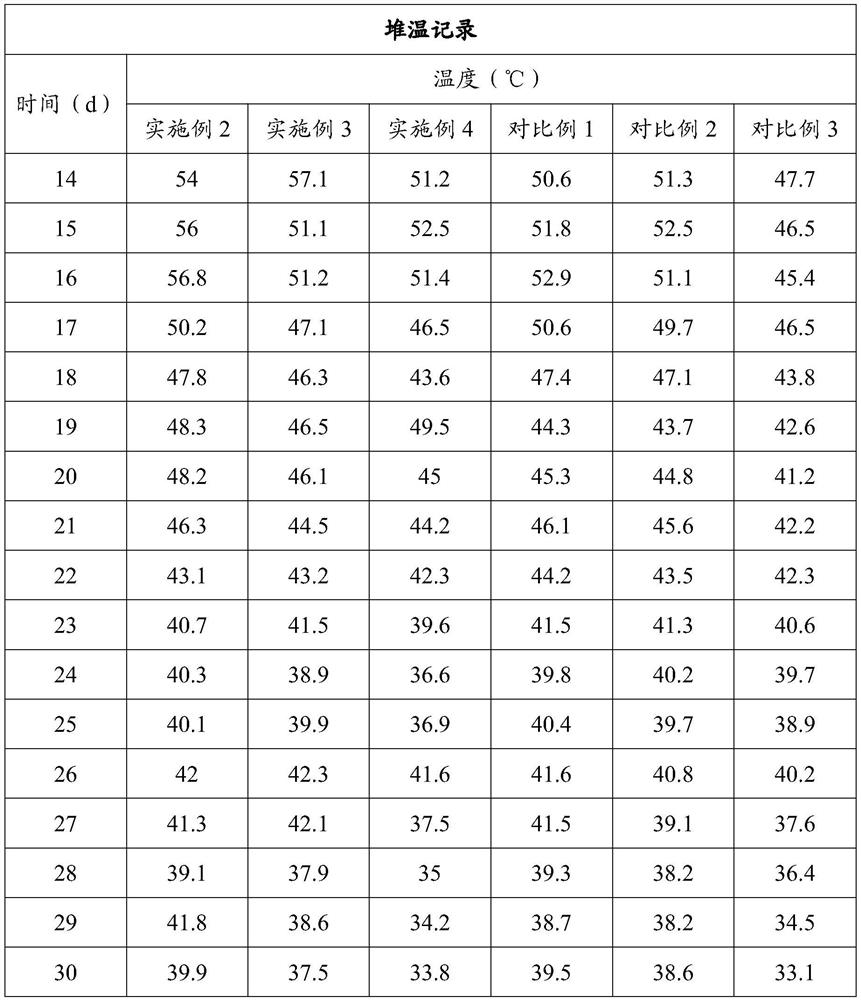

[0050] Take respectively 1000kg of refined cotton sludge, 160kg of green foxtail algae, 600kg of cow dung, 240kg of rice straw, and 2kg of the composite bacterial agent obtained in Example 1, and mix uniformly to obtain a mixture with a moisture content of 60% and a carbon-to-nitrogen ratio of 28:1. For composting, place a temperature monitoring sensor in the heap for primary fermentation, turn over every 4 days, perform secondary fermentation after 12 days of fermentation, turn over every 7 days, and obtain organic fertilizer after 18 days of fermentation.

[0051] After the first fermentation, the organic matter content was 56.2%, and the water content was 39.54%. After the second fermentation, the organic matter content of the heap was 79.0%, and the water content was 25.07%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com