CdMoO4 microsphere catalyst with photocatalytic performance as well as preparation method and application of CdMoO4 microsphere catalyst

A catalyst and photocatalysis technology, applied in the field of photocatalysis, can solve the problems of limited large-scale application and low quantum efficiency, and achieve the effects of stable structure, simple preparation method and strong dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

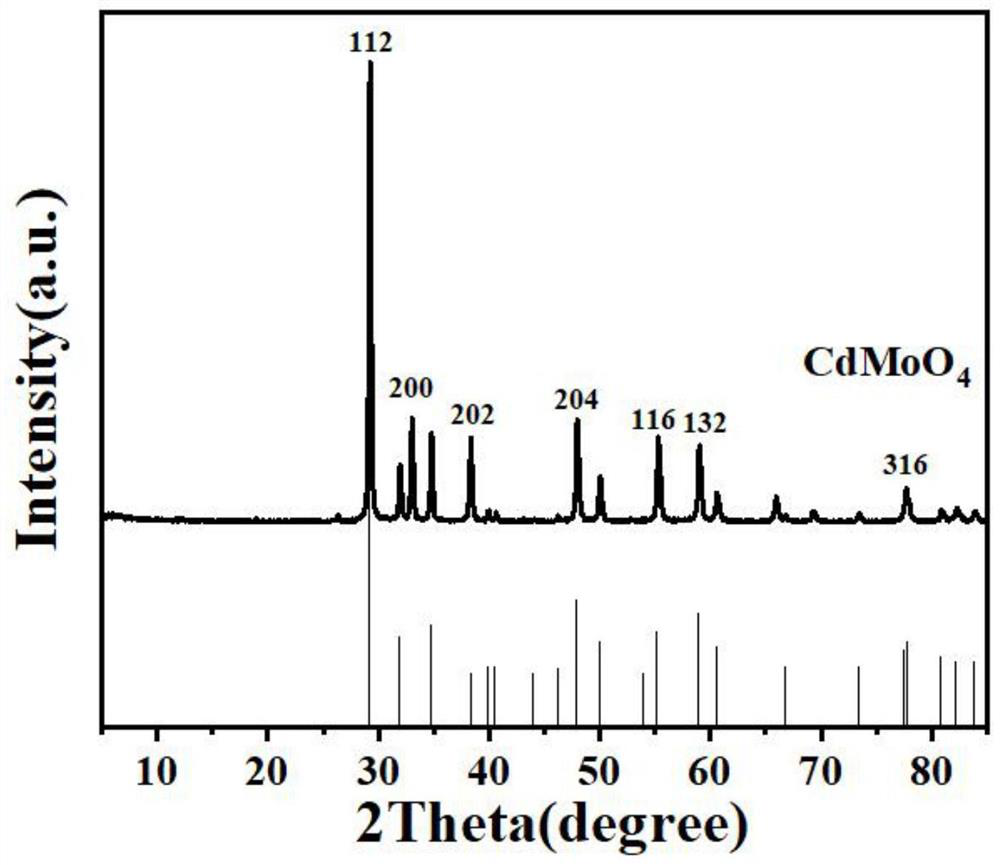

[0023] This example provides a CdMoO with photocatalytic properties 4 Microsphere catalyst, its preparation method, comprises the following steps:

[0024] (1) Add 500mg of polyacrylic acid, 350μL of ammonia water and 100mg of ammonium molybdate into the container, stir and react at room temperature for 2 hours, after stirring and mixing evenly, slowly add 300mL of isopropanol into the solution in the container, and then Add 250 mg of cadmium chloride 2.5 hydrate to the solution, and stir and react at room temperature for 10 h;

[0025] (2) Centrifuge the obtained turbid solution, dry the obtained product in an oven for 6 hours, place it in a muffle furnace, control the temperature rise to 400°C at a heating rate of 5°C / min, and calcinate at 400°C for 2h to obtain CaO 4 microsphere catalyst. The CdMoO 4 The particle size of the microsphere catalyst is 100-150 nm, which is a microsphere with stable structure, good dispersibility and uniform particle size.

Embodiment 2

[0027] This example provides a CdMoO with photocatalytic properties 4 Microsphere catalyst, its preparation method, comprises the following steps:

[0028] (1) Add 680mg of polyacrylic acid, 400μL of ammonia water and 200mg of ammonium molybdate into the container, stir and react at room temperature for 2.5h, after stirring and mixing evenly, slowly add 340mL of isopropanol into the solution in the container, after the reaction is complete Then add 350 mg cadmium chloride 2.5 hydrate to the solution, and stir and react at room temperature for 11 h;

[0029] (2) Centrifuge the obtained turbid solution, dry the obtained product in an oven for 8 hours, place it in a muffle furnace, control the temperature to 430°C at a rate of 5°C / min, and calcinate at 430°C for 3h to obtain CaO 4 microsphere catalyst. The CdMoO 4 The particle size of the microsphere catalyst is 100-150 nm, which is a microsphere with stable structure, good dispersibility and uniform particle size.

Embodiment 3

[0031] This example provides a CdMoO with photocatalytic properties 4 Microsphere catalyst, its preparation method, comprises the following steps:

[0032] (1) Add 900mg of polyacrylic acid, 450μL of ammonia water and 320mg of ammonium molybdate into the container, stir and react at room temperature for 4 hours, stir and mix evenly, slowly add 500mL of isopropanol to the solution in the container, and then Add 450 mg of cadmium chloride 2.5 hydrate to the solution, and stir for 12 hours at room temperature;

[0033] (2) Centrifuge the obtained turbid solution, dry the obtained product in an oven for 10 hours, place it in a muffle furnace, control the temperature rise to 500°C at a heating rate of 5°C / min, and calcinate at 500°C for 4h to obtain CaO 4 microsphere catalyst. The CdMoO 4 The particle size of the microsphere catalyst is 100-150 nm, which is a microsphere with stable structure, good dispersibility and uniform particle size.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com