Composite multi-component collagen microemulsion filler and preparation method thereof

A collagen and filler technology, applied in the field of medical cosmetology, can solve the problems of skin side effects, single use effect, poor product stability, etc., achieve good biocompatibility, delay skin aging, and improve the effect of supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

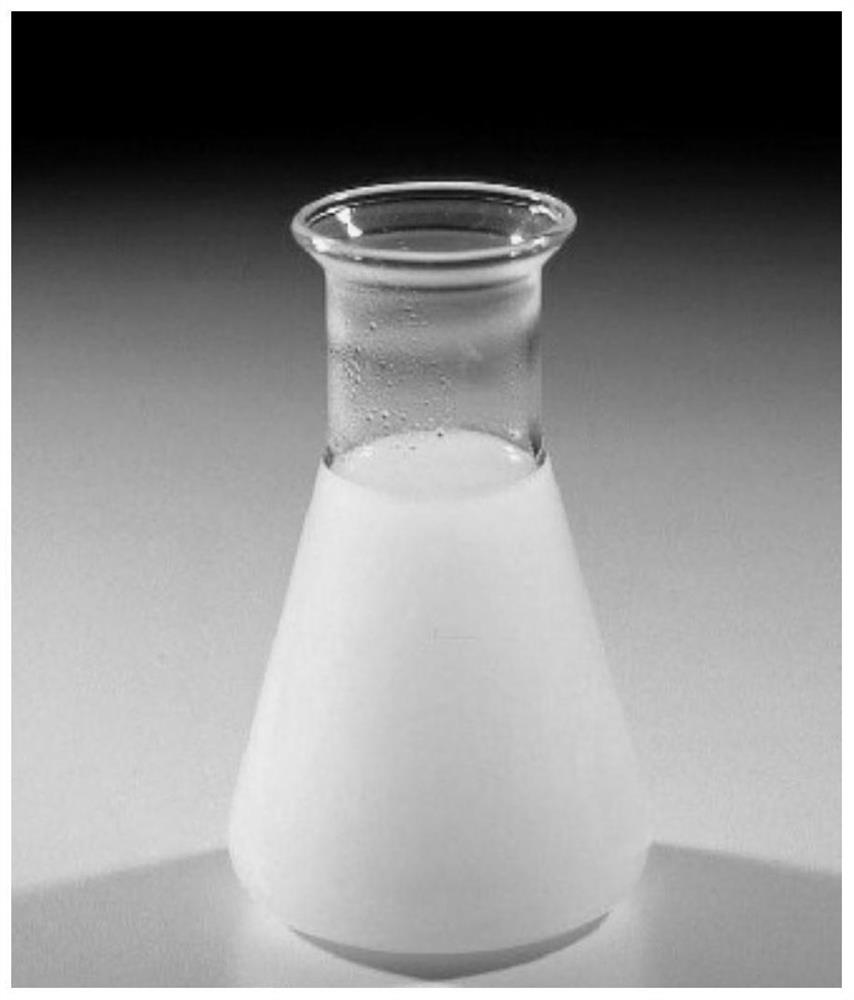

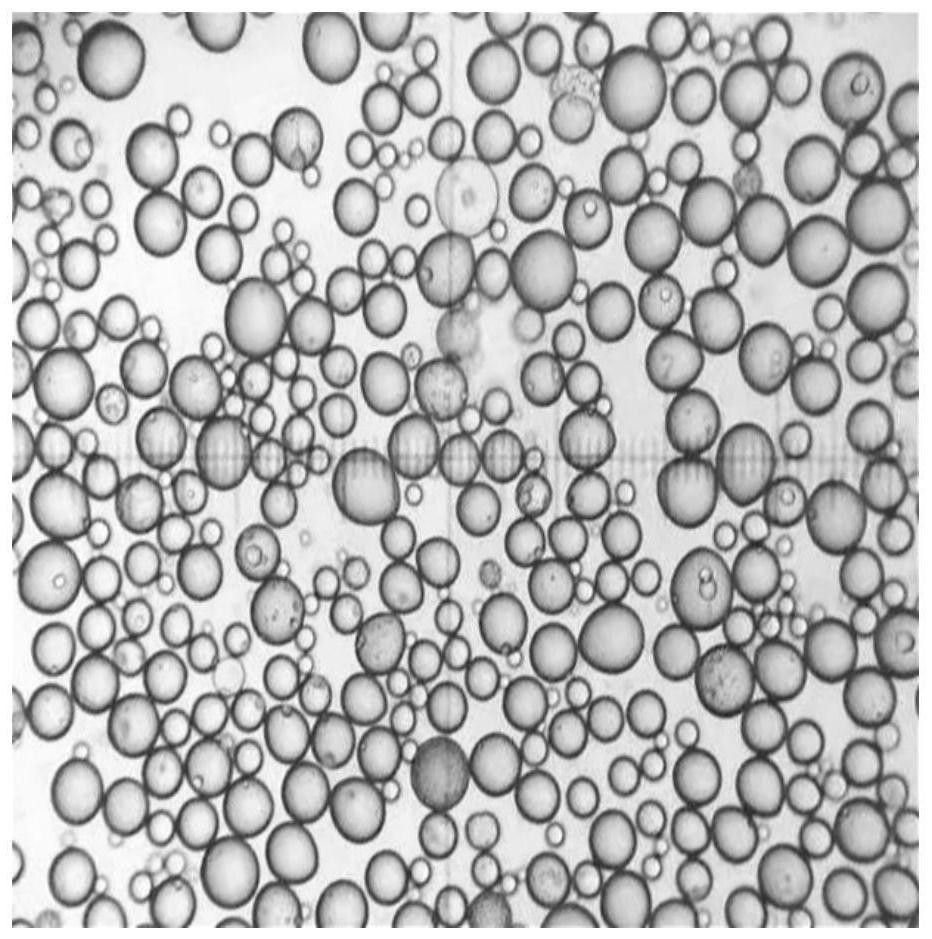

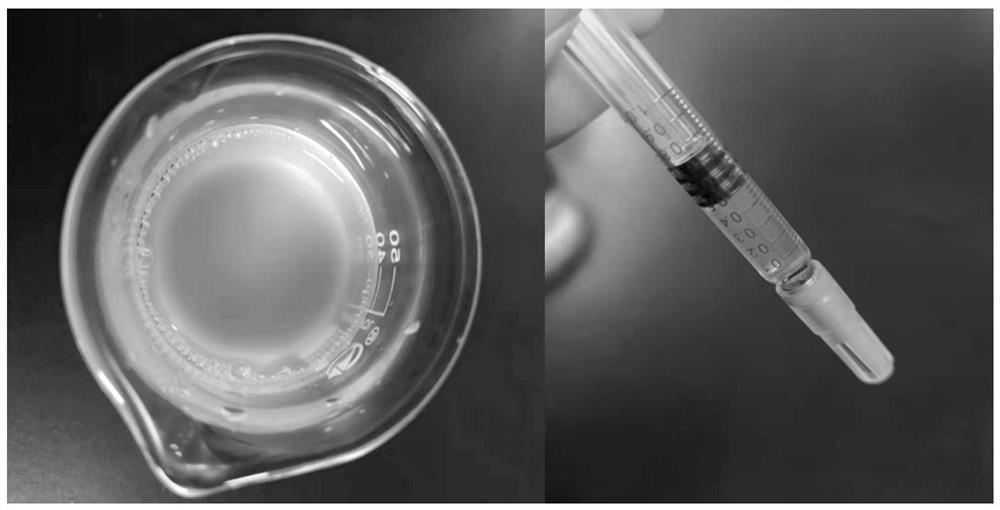

[0035] 1. Preparation of composite multi-component collagen microemulsion filler

[0036] (1) Preparation of matrix solution: add injection-grade sodium chloride to the injection-grade phosphate buffer, filter and sterilize with a 0.22 μm filter to obtain a phosphate matrix solution containing 0.9% sodium chloride;

[0037] (2) Take half of the above matrix solution, add 0.5g of vitamin E, 0.06g of sodium carboxymethyl cellulose, 1.6g of soybean lecithin, and 2.0g of poloxamer into the matrix solution, heat to 60°C, and stir until completely Dissolve, filter and sterilize through a 0.22 μm filter to obtain the oil phase;

[0038] (3) Add 0.1g of ceramide, 1.8g of proanthocyanidin, 0.5g of vitamin C, 0.1g of vancomycin, 0.3g of tetracaine hydrochloride, and 30mg of diclofenac into the remaining matrix solution, stir magnetically until completely dissolved, and obtain water Mutually;

[0039] (4) Emulsify the above-mentioned oil phase and water phase with a high-speed stirring...

Embodiment 2

[0045] 1. Preparation of composite multi-component collagen microemulsion filler

[0046] (1) Preparation of matrix solution: add injection-grade sodium chloride to the injection-grade phosphate buffer, filter and sterilize with a 0.22 μm filter to obtain a phosphate matrix solution containing 0.9% sodium chloride;

[0047] (2) Take half of the above matrix solution, add 0.5g of vitamin E, 0.06g of sodium carboxymethyl cellulose, 1.6g of soybean lecithin, and 2.0g of poloxamer into the matrix solution, heat to 60°C, and stir until completely Dissolve, filter and sterilize through a 0.22 μm filter to obtain the oil phase;

[0048] (3) Preparation of collagen microemulsion filler:

[0049] Take the remaining matrix solution to prepare collagen solutions with 40 mg / mL and 10 mg / mL of type I collagen and type III collagen (the mass ratio of the two is 4:1), add 20 mg hyaluronic acid, and use Mix it evenly with a high-pressure homogenizer, place it in a vacuum drying oven, adjust...

Embodiment 3

[0055] 1. Preparation of composite multi-component collagen common filler

[0056] (1) Preparation of matrix solution: Add injection-grade sodium chloride to commercially available injection-grade phosphate buffer, filter and sterilize with a 0.22 μm filter to obtain a sterile phosphate matrix solution containing 0.9% sodium chloride ;

[0057] (2) Collagen homogenate: Take part of the matrix solution to make collagen solutions with the contents of type I collagen and type III collagen (the mass ratio of the two is 4:1) respectively 40mg / mL and 10mg / mL, add Finally, mix it evenly with a high-pressure homogenizer;

[0058] (3) Preparation of mixed filler: add vitamin E 0.5g, sodium carboxymethylcellulose 0.06g, soybean lecithin 1.6g, and poloxamer 2.0g to the remaining matrix solution, heat to 60°C to dissolve, and then add nerve Amide 0.1g, proanthocyanidin 1.8g, vitamin C 0.5g, vancomycin 0.1g, tetracaine hydrochloride 0.3g, diclofenac 30mg, hyaluronic acid 30mg, collagen h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com