Preparation method and application of composite white carbon black

A technology of white carbon black and concentration, applied in the field of preparation of composite white carbon black, can solve the problems of single function, reduced strength of rubber and plastic, etc., and achieve the effects of simple production process, excellent performance and good economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] Preparation of Modified Composite Silica

[0033] (1) Preparation process:

[0034] A) configure a certain concentration of sodium silicate or water glass, add a certain amount of surfactant, and start mechanical stirring;

[0035] B) Keep the water glass solution at a constant temperature of 40-100°C in a water bath, continuously mechanically stir, add a certain concentration of TiCl4 solution, and control the adding speed.

[0036] C) After adding TiCl4, add a certain concentration of hydrochloric acid or sulfuric acid, control the adding speed, stop adding when the pH value reaches 9-10, turn off the stirring, and let it stand for a while.

[0037] D) Filter the solution, put the filter cake into a constant temperature solution, control a certain concentration, stir it mechanically for half an hour, and let it stand for a period of time.

[0038] E) Filter and wash with water for more than three times, and spray dry at 450°C to obtain a finished composite powder. ...

Embodiment 1

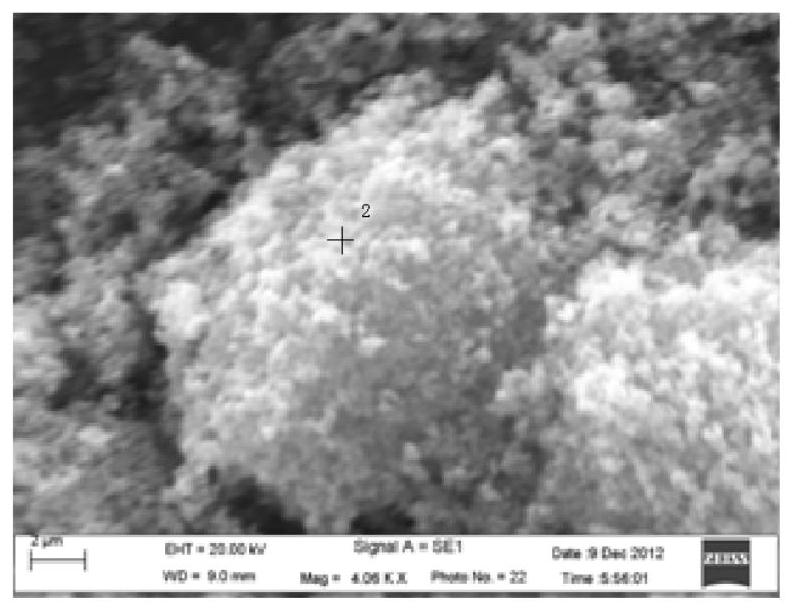

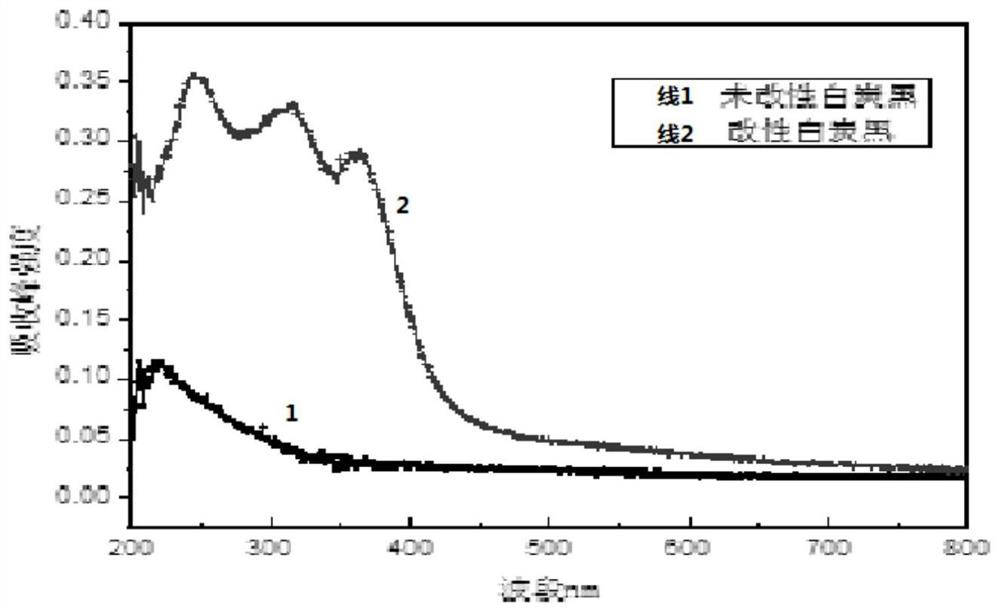

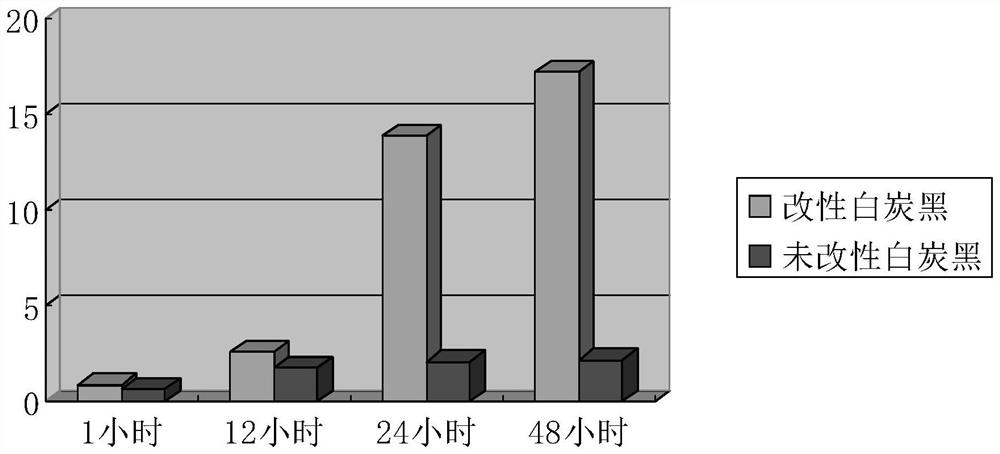

[0053] 1.1%TiO 2 Preparation of Modified Composite Silica

[0054] SiO 2 Concentration of 1g / L sodium silicate solution 500mL placed in 90 ℃ water bath constant temperature, add a certain amount of surfactant 0.02g (polyethylene glycol 3% sodium dodecylbenzene sulfonate 75% lauric acid 22%), continuous mechanical Stir, add 1g / L TiCl 4 Solution 50mL, control the addition rate to 1mL / min. TiCl 4 After the addition is complete, add sulfuric acid with a concentration of 0.2N, control the addition rate to 1000mL / min, stop the addition when the pH value reaches 9.5, turn off the stirring, and let stand for 1 hour. Filter the solution, put the filter cake into a constant temperature solution at 90°C, use hydrochloric acid to control the pH value to 5, mechanically stir vigorously at 1200r / min for half an hour, and let it stand for 1 hour; filter and wash more than three times, and spray dry at 450°C to obtain a doped 1% TiO 2 Modified composite silica powder.

[0055] 2.1%TiO ...

Embodiment 2

[0061] SiO 2 Concentration 5g / L sodium silicate solution 500mL is placed in 90 ℃ water bath constant temperature, add surfactant 0.03g (polyethylene glycol 3% sodium dodecylbenzene sulfonate 75% lauric acid 22%), continue mechanical stirring, Add 5g / L concentration of TiCl 4 Solution 50mL, control the addition speed 1mL / min. TiCl 4 After the addition is complete, add sulfuric acid with a concentration of 0.2N, control the addition rate to 1000mL / min, stop the addition when the pH value reaches 9.5, turn off the stirring, and let stand for 1 hour. Filter the solution, put the filter cake into a constant temperature solution at 90°C, use hydrochloric acid to control the Ph value to 5, mechanically stir vigorously at 1200r / min for half an hour, and let it stand for 1 hour; filter and wash with water for more than three times, and spray dry at 450°C to obtain a finished composite powder.

[0062] Obtained doped 10% TiO2 modified composite silica powder, oil absorption value 2.6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com