Alloy coating, processing method thereof and antiseptic spherical tank

A technology of alloy coating and metal coating, which is applied in the field of anti-corrosion spherical tanks, can solve the problems that the safety lower limit cannot be completely determined, and achieve the effects of prolonging the safe use period and inspection period, good corrosion resistance and good combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

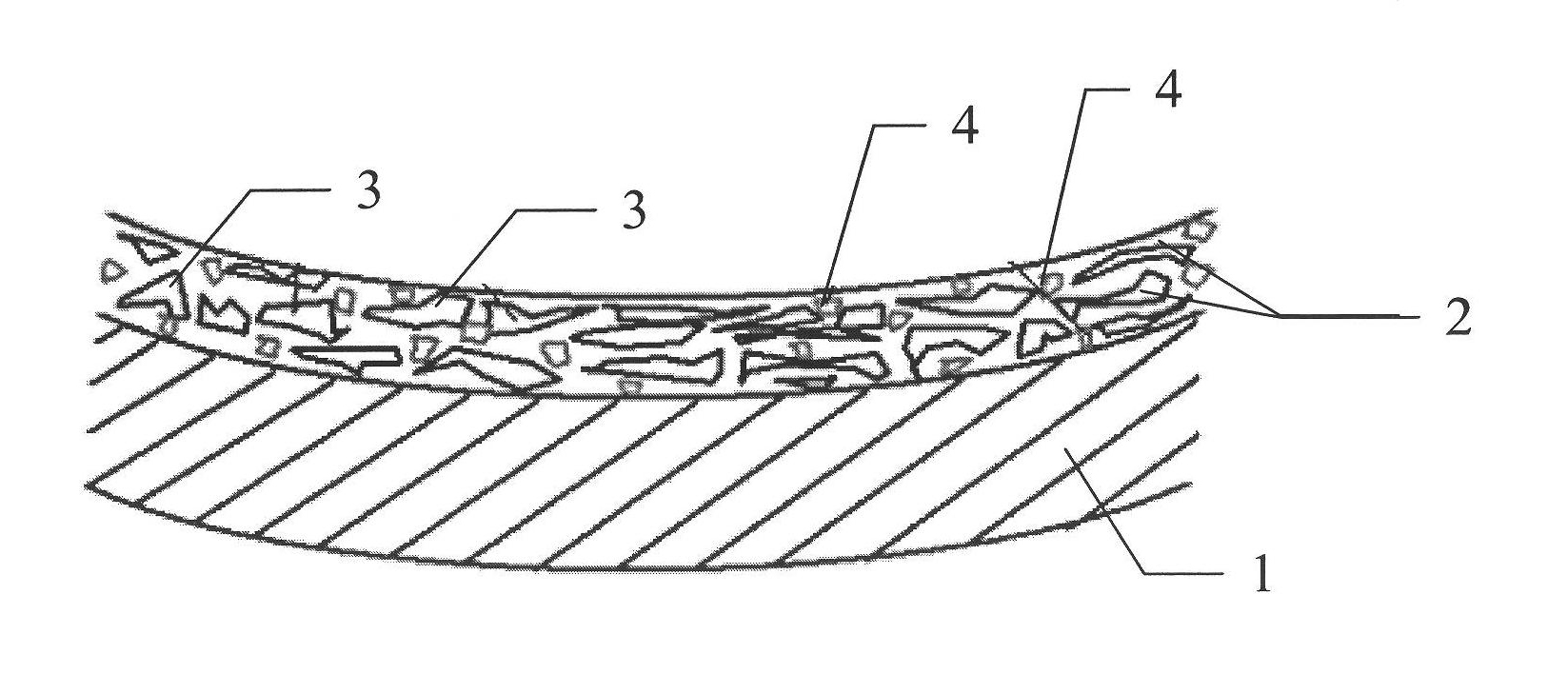

Image

Examples

Embodiment 1

[0089] The four in-service spherical tanks to be protected in this embodiment have a volume of 1000 cubic meters and an inner surface area of 484 square meters, three are liquefied petroleum gas fuel tanks, and one is a light hydrocarbon fuel tank. These four spherical tanks have been in service for more than 10 years, and the hydrogen sulfide content in the tank is very high, with an average concentration exceeding 5000 ppm. This situation has a very adverse effect on the safe operation of the spherical tank. In order to eliminate potential accidents, reduce hazards, and ensure the safe and stable long-term operation of liquid hydrocarbon spherical tanks, countermeasures must be taken to avoid equipment accidents.

[0090] (1) Sandblasting the inner wall of the spherical tank to achieve Sa3 see white level;

[0091] (2) Within 6 hours after the inner wall of the spherical tank is sandblasted, the alloy coating of the invention is sprayed by the arc spray method; the thickness of...

Embodiment 2

[0093] Example 2: Preparation before construction

[0094] (1) Quartz sand. 25 mesh corundum sand is firm, with edges and corners, no impurities, water content <1%, and it can be used after drying when it exceeds 1%.

[0095] (2) The alloy coated wire of the present invention and the special sealing agent for the alloy coating of the present invention.

Embodiment 3

[0096] Example 3: Surface pretreatment

[0097] (1) The rust removal method is sandblasting. Pressure feeding type sand feeding, sand blasting distance 200mm, sand blasting pressure 0.6MPa, sand blasting time 10s.

[0098] (2) Quality standards and testing methods: The surface treatment level meets the Sa3 level standard in GB8923 "Surface Derusting Grade Classification of Steel", that is, there is no visible grease, dirt, oxide scale, rust, paint coating and other attachments on the metal surface. The remaining traces should be only slight spots or streaks.

[0099] (3) The outlet of the air compressor must be equipped with an oil-water separator, and the outlet pressure is greater than 8kg / cm 2 ; After passing the sandblasting inspection, the first alloy layer needs to be sprayed within 6 hours.

[0100]

[0101]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Internal surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com