Hydrogel immobilized microorganism preservation method

A technology of microorganisms and hydrogels, which is applied in the direction of preservation of microorganisms, immobilization on/in organic carriers, and preparation of microspheres. Widely used in production and other issues to achieve the effect of maintaining microbial activity, easy operation, and preventing cell damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

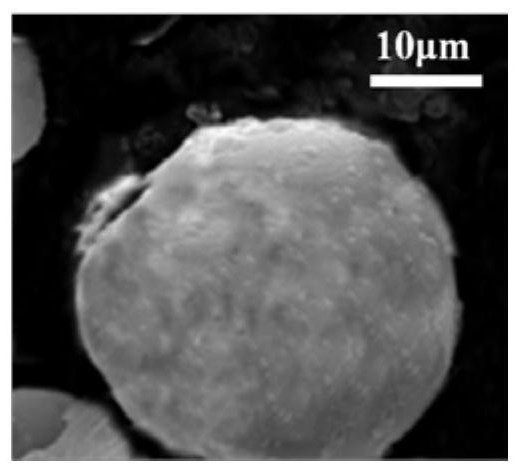

[0033] A kind of preparation of composite gel ball:

[0034] S1: Add chitosan powder to aqueous acetic acid solution (2.1%, w / w), stir until completely dissolved; add CaCO under magnetic stirring 3 (mass ratio of chitosan powder to 0.79:1), stirring for 12min, then ultrasonic for 15min; then add liquid paraffin (solid-liquid ratio of chitosan powder and paraffin is 1g:156mL), vigorously stir for 5min; 43 ℃ water bath Under the condition, add span-80 dropwise (the solid-liquid ratio of chitosan powder and span-80 is 1g: 2.1mL), stir 30min; / w) (the solid-to-liquid ratio of chitosan powder and glutaraldehyde solution is 1g: 2.2mL), carry out the crosslinking reaction for 65min; finally add N-(1,8-dimethylimidazo[1,2-a ]quinoxalin-4-yl)-1,2-ethylenediamine (mass ratio to chitosan powder is 1.87:1), after stirring for 70min, add 5M NaOH solution to adjust pH to 10.2, and adjust reaction temperature to Continue to stir and react at 74°C for 110 minutes; the reaction product is ri...

Embodiment 2

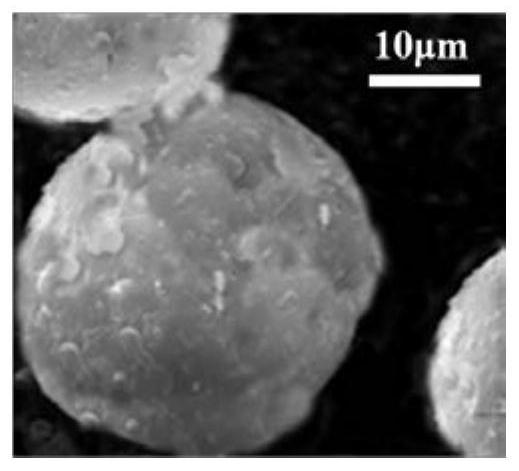

[0037] The difference between the preparation of a kind of composite gel ball and embodiment 1 is:

[0038] CaCO in step S1 3 The mass ratio of chitosan powder to chitosan powder is 0.76:1; the solid-liquid ratio of chitosan powder to glutaraldehyde solution is 1g:2mL; N-(1,8-dimethylimidazo[1,2-a] The mass ratio of quinoxalin-4-yl)-1,2-ethylenediamine to chitosan powder is 1.80:1;

[0039] Step S2 The mass ratio of the intermediate product M to sodium alginate is 1:0.8-1.2; the solid-to-liquid ratio of sodium alginate to calcium chloride solution is 0.1 g:18.4 mL.

Embodiment 3

[0041] The difference between the preparation of a kind of composite gel ball and embodiment 1 is:

[0042] CaCO in step S1 3 The mass ratio of chitosan powder to chitosan powder is 0.81:1; the solid-liquid ratio of chitosan powder to glutaraldehyde solution is 1g:2.3mL; N-(1,8-dimethylimidazo[1,2-a The mass ratio of ]quinoxalin-4-yl)-1,2-ethylenediamine to chitosan powder is 2.01:1;

[0043] Step S2 The mass ratio of intermediate product M to sodium alginate is 1:1.16; the solid-to-liquid ratio of sodium alginate to calcium chloride solution is 0.1 g:23.6 mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com