Preparation method of rice peptide chelated calcium

A technology of rice peptide and chelated calcium, applied in food science, protein-containing food ingredients, applications, etc., can solve problems affecting product quality and flavor, solvent residues, etc., to improve substrate utilization, reduce solvent pollution, and retain The effect of the original flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

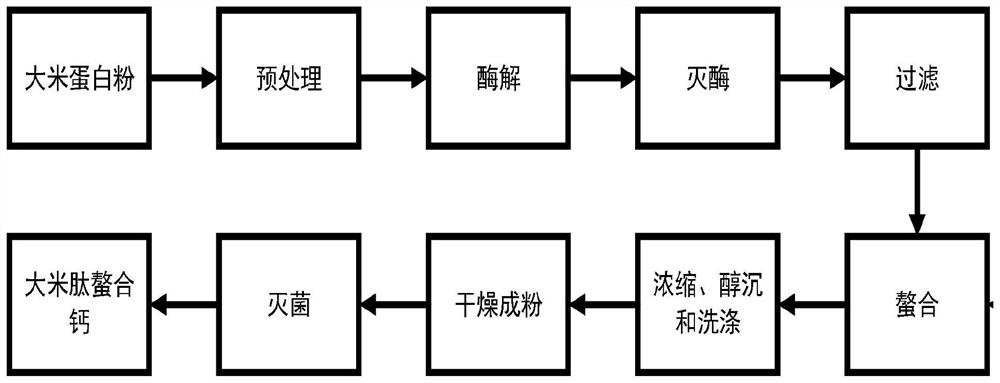

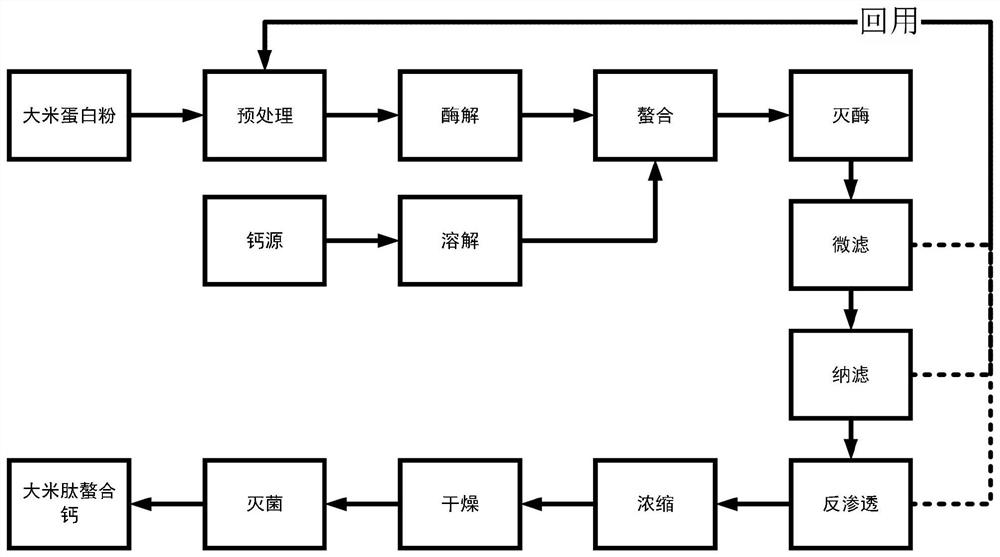

[0051] like figure 1 As shown, the method of preparing the calcium of the rice peptide chelate, the specific steps are:

[0052] (1) Pretreatment: The rice protein powder is dissolved with pure water, the material is 1: 9, and then the wet grinding is pulverized to obtain the rice proteolytic;

[0053] (2) Enzymatic solution: The rice protein pulp obtained by (1) is added to the composite protease-free solution; the mean protease is obtained; the composite protease is the alkaline protease (E0103), papain protease; enzymatic temperature 50 ° C, pH 7 The enzymatic solution is 3 h.

[0054] (3) The enzyme: the enzymatic hydrolyzate obtained by the (2) is warmed to 90 ° C for 10 min, and the enzyme is rt.

[0055] (4) Filtering: (3) The levotherter solution obtained by the step is obtained by ceramic membrane microfiltration and nanofiltration, and the mean peptide liquid is collected;

[0056] The ceramic of the ceramic is filtered in a filter film, and the molecular weight of the m...

example 1

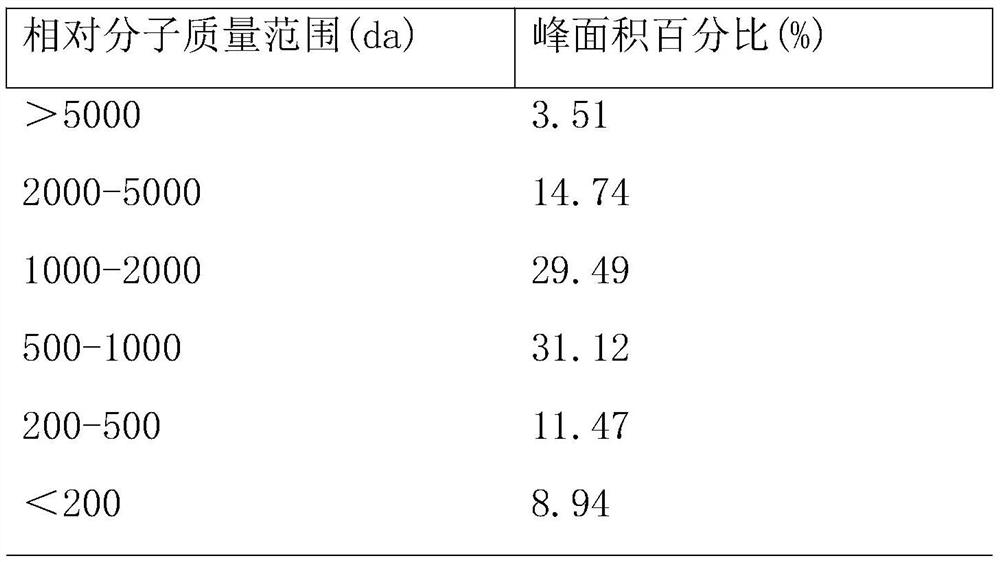

[0059] Table 2 Example 1 rice peptide amino acid composition

[0060]

[0061]

[0062] (5) Chelating: Calcium chloride, coastal calcium chloride, lifting and reaction to the rice peptide solution to the calcium peptide solution, and obtain the rice peptide chelate calcium fluid;

[0063] The above chelating reaction calcium source substance is formulated into a solution of 10% (m / w) to the rice peptide solution, the chelate reaction temperature is 50 ° C, pH 7, chelating 1 h.

[0064] (6) Concentration, alcohol sink and washing: Step (5) The liquid is concentrated to 1 / 2 of the original volume, add 3 times volume of 95 ethanol precipitation, centrifugal or filtration to collect precipitation, and use 4 times volume 95 Ethanol washing, remove uncharged calcium ions and peptides;

[0065] (7) Drying into powder; the washed rice peptide chelate is dried with a vacuum drying tank to control the drying temperature of 40 ° C. After drying, pulverized over 100 mesh sieves, and pow...

Embodiment 2

[0069] like figure 1 As shown, the method of preparing the calcium of the rice peptide chelate, the specific steps are:

[0070] (1) Preprocessing: The rice protein powder is dissolved with pure water, the material is 1: 4, and then the wet grinding is pulverized to give the rice proteolytic;

[0071] (2) Enzymatic hydrolysis: The rice protein pulp obtained by Step is added to the composite protease enzymatic solution; the rice protease is obtained; the composite protease is a basic protease (E0103), a flavor protease. The enzymatic hydrolysis temperature is 55 ° C, pH 6, and the enzymatic solution is 5 h.

[0072] (3) Upsenase: The enzymatic hydrolyzate obtained by Step is warmed to 90 ° C for 20 min, and the enzyme is rt.

[0073] (4) Filtering: The ulcogenating liquid obtained by C is collected by ceramic membrane microfiltration and nanofiltration, and the rice peptide solution is collected;

[0074] The ceramic described above is a film intercept molecular weight at 20 kDa, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com