Toughening type steel bar anti-corrosion powder coating and preparation method thereof

A powder coating and toughening technology, used in powder coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems of poor low temperature toughness and easy to be corroded, so as to improve toughness, enhance anti-corrosion performance, and improve anti-corrosion performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

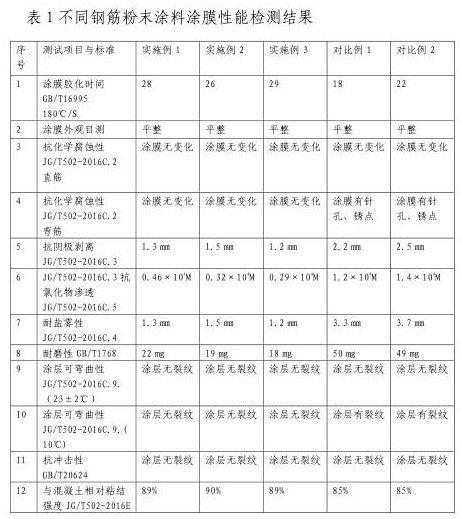

Examples

Embodiment 1

[0037] A toughened anticorrosion powder coating for steel bars: it is characterized in that: it is made of the following components by weight:

[0038] Base powder 60kg, bonding agent polyethylene wax powder 0.5kg, loosening agent alumina C 0.15kg, glass flakes 2kg.

[0039] The weight of each component of the base powder is: E-12 epoxy resin 35 kg, curing agent phenolic hydroxyl resin 5.90 kg, toughening curing agent polyurethane B1530 4.70 kg, curing accelerator Curezol C11Z 0.66 kg, leveling agent GLP288 0.53 kg , Defoamer benzoin 0.60kg, filler precipitated barium sulfate 7.76kg, filler talc powder 0.42kg, titanium dioxide 3.32kg, pigment phthalocyanine blue 0.42kg, coupling agent W-6670 0.69kg.

[0040] Phenolic hydroxyl resin (self-made), hydroxyl value 0.5 mol / 100g. The average particle size of the base powder is 20-45 μm.

[0041] The preparation method comprises the following steps:

[0042] (1) Preparation of base powder:

[0043] a. Put the components of the abo...

Embodiment 2

[0054] A toughened anticorrosion powder coating for steel bars: it is characterized in that: it is made of the following components by weight:

[0055] Base powder 60kg, bonding agent fluorine-modified polyethylene wax powder 0.4kg, loosening agent fumed silica 0.1kg, glass flake 2.3kg.

[0056] The weight of each component of the base powder is: E-12 epoxy resin 35 kg, curing agent phenolic hydroxyl resin 5.36 kg, toughening curing agent polyurethane BF1320 4.96 kg, curing accelerator Curezol C17Z 0.57 kg, leveling agent GLP288 0.58 kg , Defoamer polyethylene wax powder 0.50kg, filler precipitated barium sulfate 7.1kg, filler light calcium carbonate 1.62kg, titanium dioxide 3.24kg, pigment carbon black 0.49kg, coupling agent ND-782 0.58kg.

[0057] Phenolic hydroxyl resin (self-made), the hydroxyl value is 0.5 mol / 100g, and the average particle size of the primer is 20-45μm.

[0058] The preparation method and coating detection method are the same as in Example 1. The test ...

Embodiment 3

[0060] A toughened anticorrosion powder coating for steel bars: it is characterized in that: it is made of the following components by weight:

[0061] Base powder 60kg, bonding agent polytetrafluoroethylene wax powder 0.5kg, loosening agent alumina C 0.15kg, glass flakes 2.7kg.

[0062] The weight of each component of the base powder is: E-12 epoxy resin 35 kg, curing agent phenolic hydroxyl resin 5.73 kg, toughening curing agent polyurethane AdditoL X1428 5.31 kg, curing accelerator Curezol C11Z 0.62 kg, leveling agent GLP2880. 66kg, defoamer polypropylene composite micropowder wax 0.54kg, filler precipitated barium sulfate 6.79kg, filler silicon powder 0.83kg, filler titanium dioxide 3.32kg, pigment phthalocyanine green 0.50kg and coupling agent ND-783 0.70kg.

[0063] Phenolic hydroxyl resin (self-made), the hydroxyl value is 0.5 mol / 100g, and the average particle size of the primer is 20-45μm.

[0064] The preparation method and coating detection method are the same as i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com