Preparation method and application of phosphorized WS2 nanosphere catalyst

A technology of catalysts and nanospheres, applied in the field of nanomaterials, can solve the problems of electrochemical research without WS2, and achieve the effects of controllable shape, simple operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

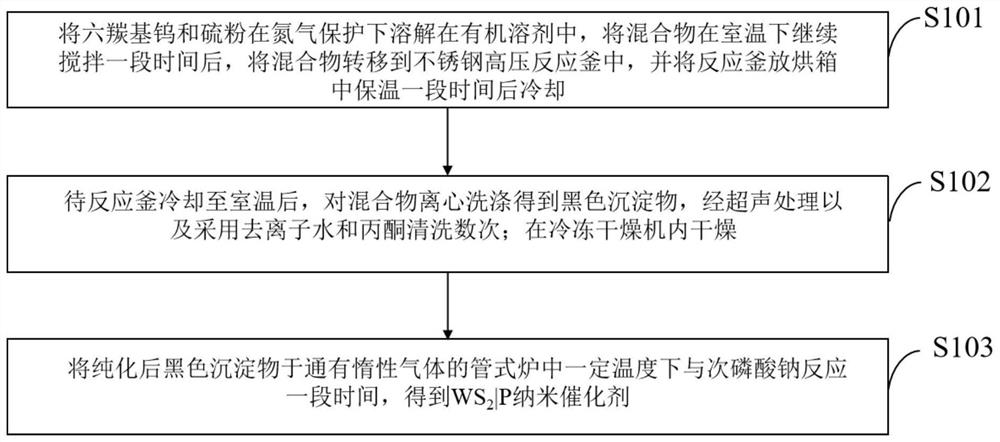

[0040] Such as figure 1 As shown, the WS provided by the present invention2 The preparation method of P nanosphere catalyst comprises the following steps:

[0041] S101 Dissolve tungsten hexacarbonyl and sulfur powder in an organic solvent under the protection of an inert gas, and mix them uniformly at room temperature to obtain a brown mixed solution; fully react the brown mixed solution in a high-pressure reactor at 100°C-250°C , the brown mixed solution is fully reacted for 10-24h;

[0042] S102 After cooling the reacted autoclave to room temperature, the mixture is centrifuged to obtain a black precipitate, which is purified;

[0043] S103 React the purified black precipitate with sodium hypophosphite for 2-3 hours in a tube furnace with inert gas at 200°C-300°C to obtain WS 2 |P nanosphere catalyst.

[0044] The WS provided by the embodiment of the present invention 2 The preparation method of P nanosphere catalyst specifically comprises the following steps:

[0045]...

Embodiment 1

[0054] Example 1: Preparation of WS according to the invention 2 |P nanosphere catalyst

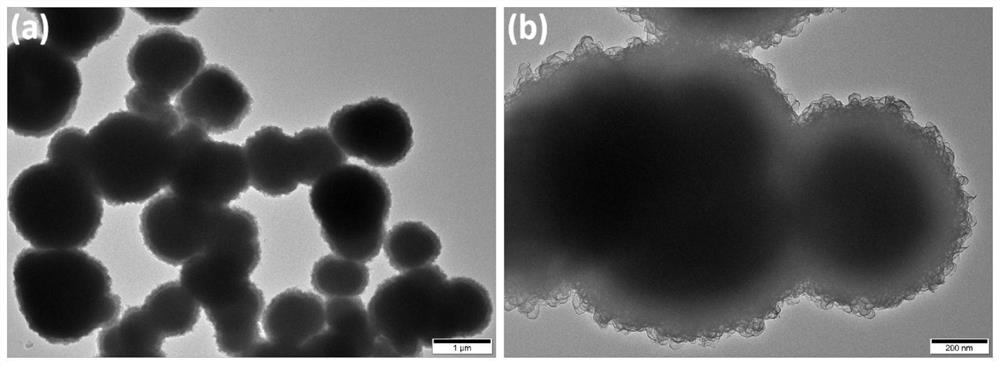

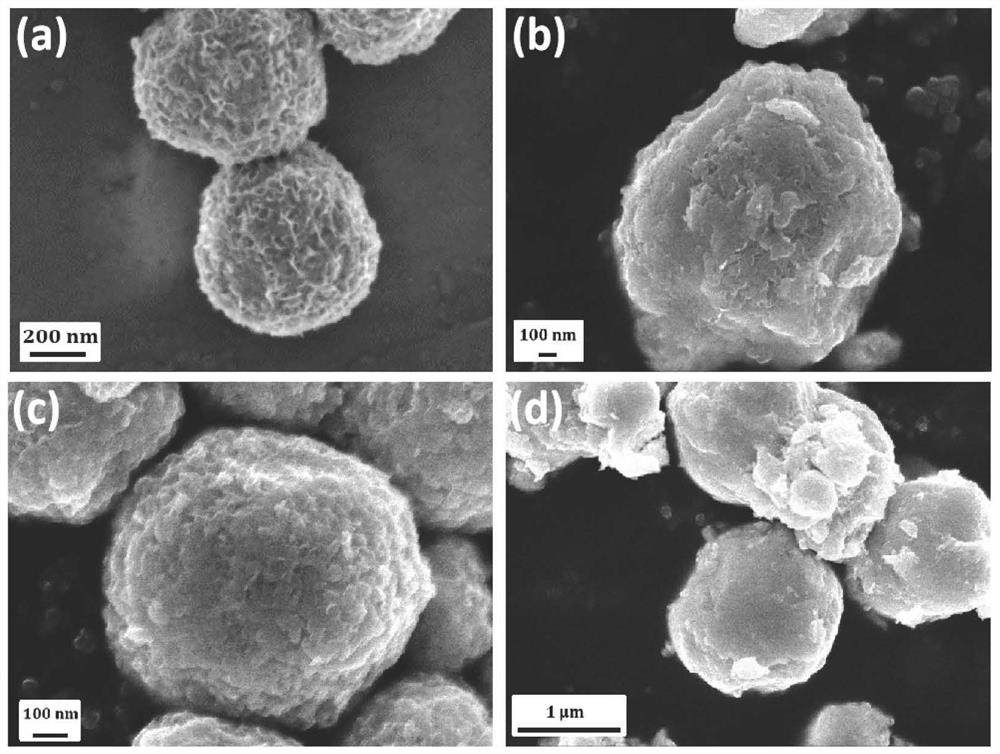

[0055] First, 0.33 g of sublimed sulfur powder and 1.76 g of tungsten hexacarbonyl were dissolved in 35 mL of organic solvent under the protection of nitrogen, and stirred rapidly at room temperature for 20 min, and then the mixture was transferred to a stainless steel autoclave, and the high pressure The reactor was placed in an oven at 230°C and kept for 24 hours; finally, after the temperature of the autoclave was cooled to room temperature, the mixture was centrifuged and washed to obtain a black precipitate, which was dispersed by ultrasonic waves, and deionized water and acetone were used to Alternately washed several times, finally collected by centrifugation, dried in a vacuum freeze dryer for 2 hours to obtain a purified black precipitate; the purified black precipitate was reacted with sodium hypophosphite at 300°C in a tube furnace with argon for 2 hours, Get WS 2 |P nanosphe...

Embodiment 2

[0060] Embodiment 2: WS provided by the embodiment of the present invention 2 |P nanosphere catalyst includes the following steps:

[0061] First, 0.33 g of sublimed sulfur powder and 1.76 g of tungsten hexacarbonyl were dissolved in 35 mL of organic solvent under the protection of nitrogen, and stirred rapidly at room temperature for 20 min, and then the mixture was transferred to a stainless steel autoclave, and the high pressure The reactor was placed in an oven at 230°C and kept for 24 hours; finally, after the temperature of the autoclave was cooled to room temperature, the mixture was centrifuged and washed to obtain a black precipitate, which was dispersed by ultrasonic waves, and deionized water and acetone were used to Alternately washed several times, finally collected by centrifugation, dried in a vacuum freeze dryer for 2 hours to obtain a purified black precipitate; the purified black precipitate was reacted with sodium hypophosphite at 200°C in a tube furnace wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com