Method for regenerating electrode by using waste lithium battery and leaching residues

A waste lithium battery and leaching slag technology, which is applied in the field of solid waste resource utilization, can solve the problems of increased recycling cost, low price, waste of manganese metal, etc., achieve excellent electrochemical performance, short recycling process, and expand recycling economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

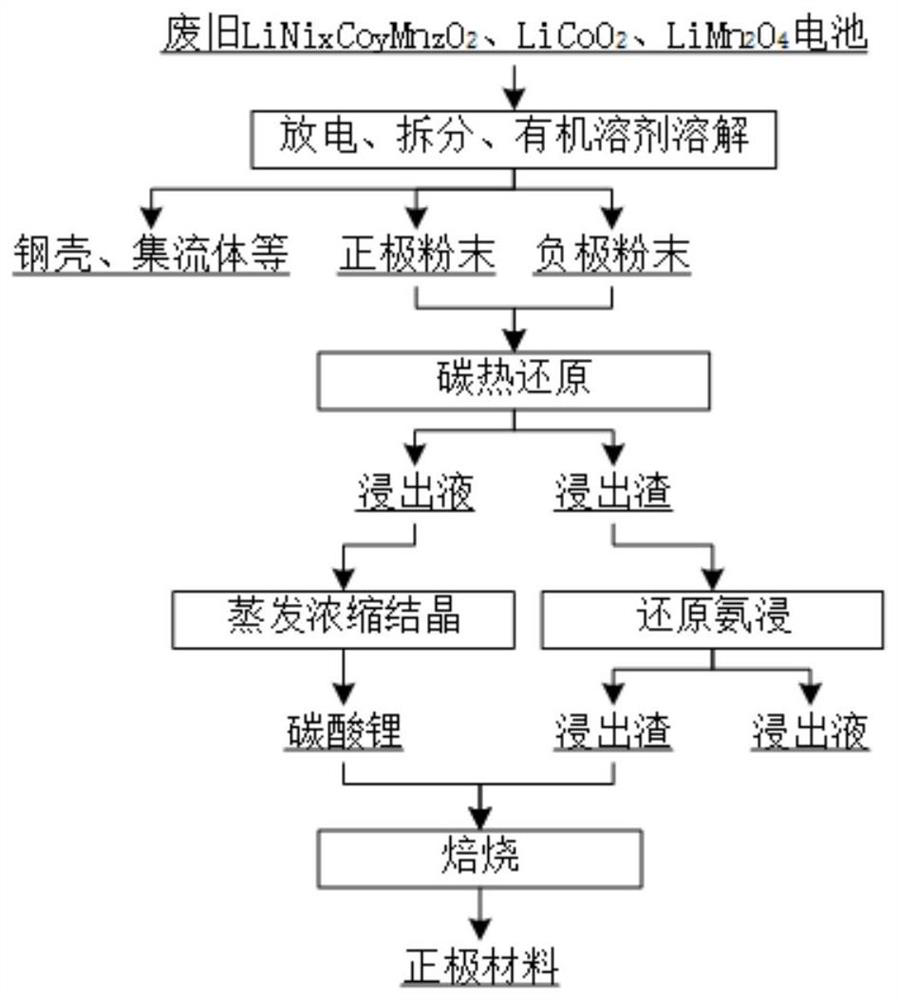

Method used

Image

Examples

Embodiment 1

[0031] This embodiment includes the following steps:

[0032] (1) The waste LiNi x co y mn z o 2 、LiCoO 2 and LiMn 2 o 4 Put the battery in 3M NaCl solution and discharge it for 12 hours. Take out the discharged battery and disassemble the lithium-ion battery into a casing, a separator, a positive electrode piece and a negative electrode piece in a glove box filled with argon gas. Dissolve the organic binder on the electrode piece in hot NMP at ℃, wash the separated positive and negative electrode materials with deionized water, dry them in a blast drying oven at 90°C for 12 hours, and grind them evenly to obtain waste mixed positive and negative electrode graphite powder. Aluminum foil and copper foil current collectors are recycled directly.

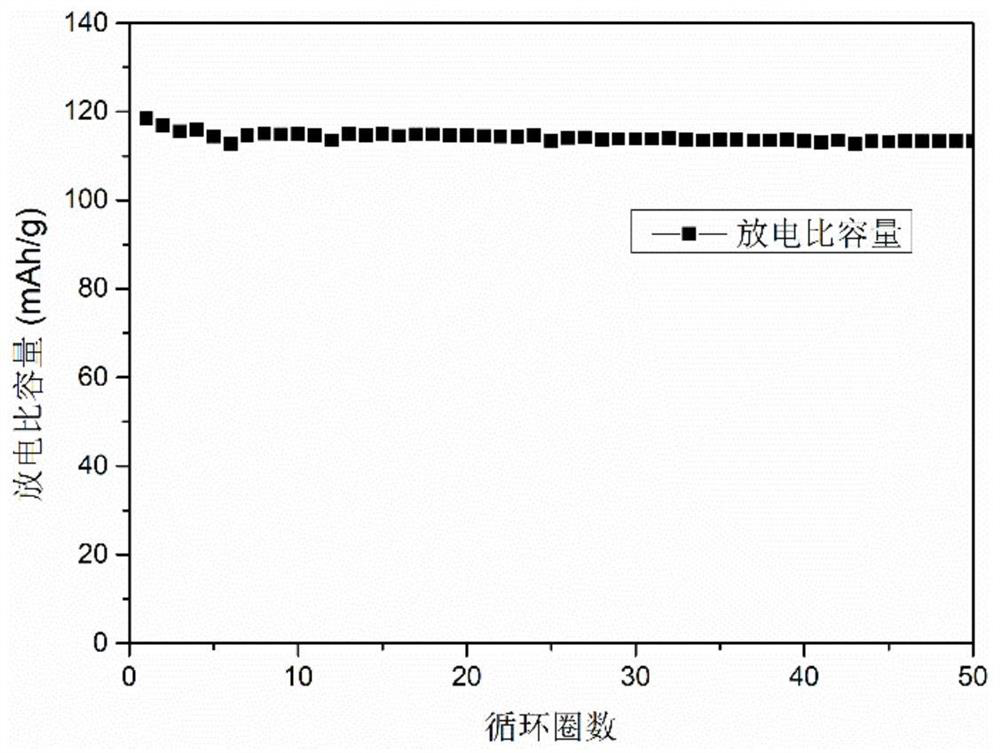

[0033] (2) Take 10 g of mixed positive electrode powder and 2 g of negative electrode graphite powder, and use a ball mill to mechanically mix for 2 hours to obtain a uniformly mixed powder, which is placed in an argon atmospher...

Embodiment 2

[0041] This embodiment includes the following steps:

[0042] (1) The waste LiNi x co y mnz o 2 、LiCoO 2 and LiMn 2 o 4 Put the battery in 3M NaCl solution and discharge it for 12 hours. Take out the discharged battery and disassemble the lithium-ion battery into a casing, a separator, a positive electrode piece and a negative electrode piece in a glove box filled with argon gas. Dissolve the organic binder on the electrode piece in hot NMP at ℃, wash the separated positive and negative electrode materials with deionized water, dry them in a blast drying oven at 90°C for 12 hours, and grind them evenly to obtain waste mixed positive and negative electrode graphite powder.

[0043] (2) Take 8 g of mixed positive electrode powder and 2 g of negative electrode graphite powder, and use a ball mill to mechanically mix for 1 h to obtain a uniformly mixed powder, which is placed in an argon atmosphere tube furnace for carbothermal reduction sintering, the reaction temperature is...

Embodiment 3

[0049] This embodiment includes the following steps:

[0050] (1) The waste LiNi x co y mn z o 2 、LiCoO 2 and LiMn 2 o 4 Put the battery in 3M NaCl solution and discharge it for 12 hours. Take out the discharged battery and disassemble the lithium-ion battery into a casing, a separator, a positive electrode piece and a negative electrode piece in a glove box filled with argon gas. Dissolve the organic binder on the electrode sheet in hot NMP at ℃, wash the separated positive and negative electrode materials with deionized water, dry them in a blast drying oven at 80°C for 12 hours, and grind them evenly to obtain waste mixed positive and negative electrode graphite powder.

[0051] (2) Take 10 g of mixed positive electrode powder and 2 g of negative electrode graphite powder, and use a ball mill to mechanically mix for 2 hours to obtain a uniformly mixed powder, which is placed in an argon atmosphere tube furnace for carbon thermal reduction sintering, the reaction tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com