Solid lubricating protective coating as well as preparation method and application thereof

A protective coating and solid lubrication technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of wear-resistant life, bearing capacity and salt spray resistance at the same time, and achieve excellent aluminum corrosion resistance and Thermal stability, strong impact resistance and toughness, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a preparation method of the solid lubricating protective coating described in the above technical solution, comprising the following steps:

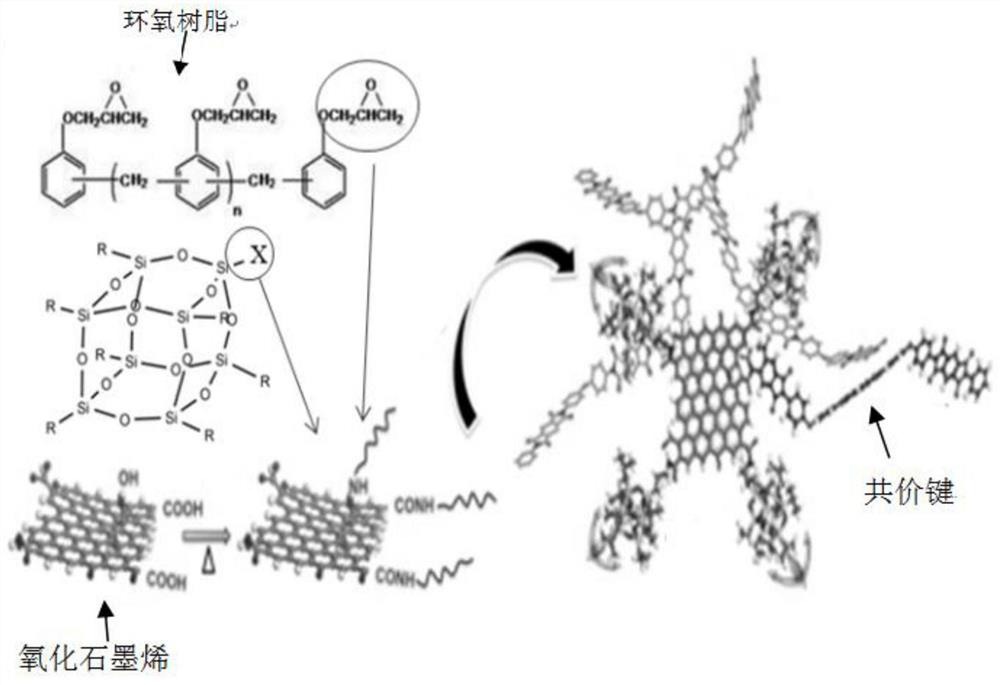

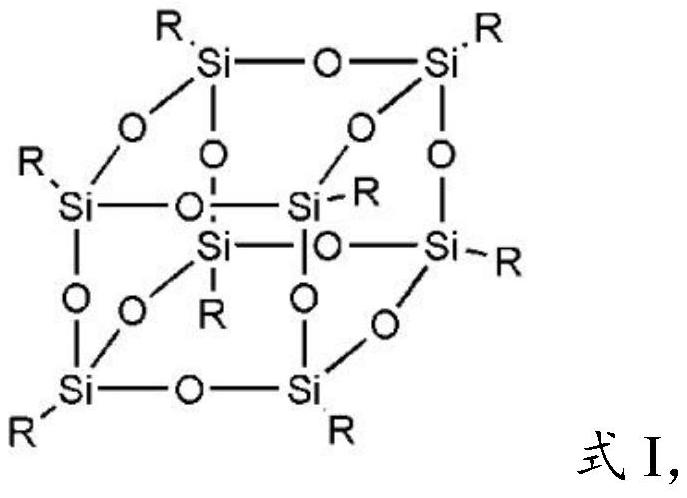

[0050] Mix octaammonium cage polysesquioxane with graphene oxide for covalent grafting reaction to obtain POSS / GO nano-modified filler;

[0051] mixing epoxy resin, cashew oil modified phenolic resin and the first part of mixed solvent to obtain a resin system;

[0052] Mixing the POSS / GO nano-modified filler and the resin system for modification to obtain a modified resin system;

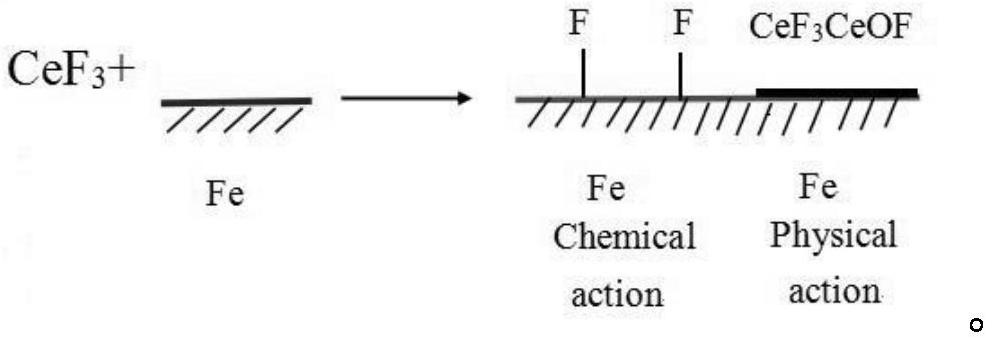

[0053] mixing molybdenum disulfide, cerium trifluoride, antimony trioxide, dibasic lead phosphite, organic bentonite and the second part of the mixed solvent to obtain an additive system;

[0054] The additive system, the modified resin system and the remaining mixed solvent are mixed to obtain the solid lubricating protective coating.

[0055] The invention mixes octaammonium cage polysemisiloxane and graphene oxi...

Embodiment 1

[0076] The solid lubricating protective coating is made of the following components: 5.0g of epoxy resin, 1.0g of cashew oil modified phenolic resin, 0.3g of octaammonium caged polysesquioxane, 0.2g of graphene oxide, and 13.0g of molybdenum disulfide g, 1.0 g of antimony trioxide, 1.0 g of cerium trifluoride, 0.50 g of organic bentonite, 0.10 g of dibasic lead phosphite, and 77.9 g of a mixed solvent. The mixed solvent is uniformly mixed with 28% ethylene glycol ether, 17% methyl ethyl ketone and 55% toluene in volume percentage.

[0077]Preparation method: (1) Using graphene oxide as the matrix, octaammonium caged polysesquioxane is covalently grafted on the surface of graphene oxide through a chemical reaction (ultrasound for 30 minutes) to prepare POSS / GO nano-modified fillers (2) take epoxy resin and cashew nut oil modified phenolic resin according to the formula, and add part of the mixed solvent in the resin, stir to make it dissolve completely; (3) introduce the POSS / G...

Embodiment 2

[0080] The solid lubricating protective coating is made of the following components: 5.50 g of epoxy resin, 2.0 g of cashew oil modified phenolic resin, 0.4 g of octaammonium caged polysesquioxane, 0.3 g of graphene oxide, and 13.5 g of molybdenum disulfide g, 1.0 g of antimony trioxide, 1.2 g of cerium trifluoride, 0.55 g of organic bentonite, 0.2 g of dibasic lead phosphite, and 75.4 g of a mixed solvent. The mixed solvent is uniformly mixed with 26% ethylene glycol ether, 18% methyl ethyl ketone and 56% toluene in volume percentage.

[0081] Its preparation method is with embodiment 1.

[0082] The prepared coating has good adhesion to the metal substrate, has strong impact resistance and toughness, and the wear life of Falex is 470 minutes under the load of 4450N, the load capacity is 11200N, the resistance to neutral salt spray is 100 hours, and the corrosion resistance of aluminum The performance, medium resistance and thermal stability are good, and the performance mee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Carrying capacity | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

| Carrying capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com