Method for preparing hydroxy fatty acid

A hydroxy fatty acid, quality technology, applied in the field of enzyme engineering, can solve the problems of separation and extraction difficulties, waste of resources, etc., to achieve the effect of reducing industrial waste, realizing recycling, and solving waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Preparation of degummed by-products. Heat the crude oil to 80°C, add phosphoric acid with 2% mass of the crude oil, and stir at high speed. When particles are generated, continue to stir and cool down to 25°C, add isothermal water, continue to stir for 10 minutes, let stand to separate layers, centrifuge, and extract the supernatant After the grease is removed, the lower layer of precipitation is the by-product of degumming, and its main component is phospholipid.

Embodiment 2

[0049] The preparation of hydroxy fatty acid comprises the steps of:

[0050] (1) Dissolve the degummed by-product obtained in Example 1 in acetonitrile, ultrasonically disperse the phospholipids in the degummed by-product, and after dispersion, remove the insoluble precipitate by centrifugation to obtain the organic phase of the substrate.

[0051] (2) Enzyme treatment: Dissolve VpPLD, PLB, UPO, and CHoX in a buffer solution with a pH of 7.0-9.0 to obtain an aqueous phase of a compound enzyme solution, wherein VpPLD and PLB are added at 200 U / g of substrate mass, and UPO is added at The substrate mass was added at 300U / g, CHoX was added at the substrate mass of 350U / g, and the enzyme activity ratio of PLB:VpPLD:UPO:CHoX in the complex enzyme was 5:5:6:7.

[0052] (3) Reaction conditions: The organic phase of the substrate and the aqueous phase of the composite enzyme solution were mixed at a volume ratio of 1:4, and rotated in an oil bath at 30° C. for 2 hours at 500 rpm.

Embodiment 3

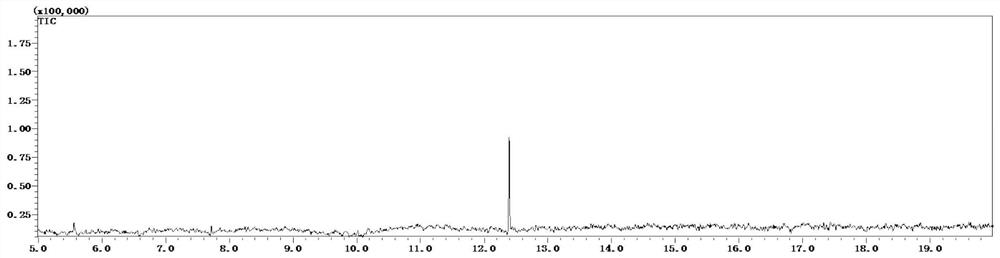

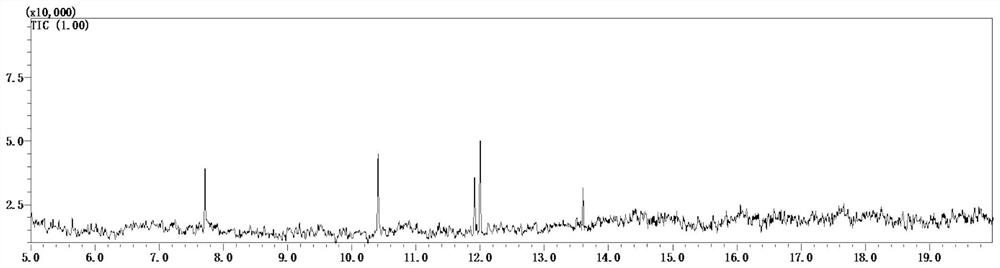

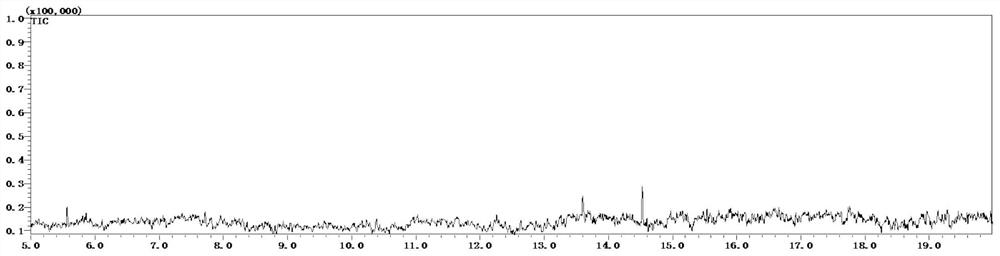

[0054] Carry out GC-MS detection to the hydroxy fatty acid mother liquor obtained in embodiment 2.

[0055] Preparation of standard products: after derivatization of existing hydroxy fatty acid standard products, GC-MS detection

[0056] Standard product processing method: 1mL of 25mM hydroxy fatty acid mother solution (dissolved in acetonitrile), add an equal amount of methyl tert-butyl ether for extraction, centrifuge, take the upper organic phase, add anhydrous sodium sulfate to remove water. Then take 400uL of the treated sample in the chromatographic bottle, add 100uL N,O-bis(trimethylsilyl)trifluoroacetamide (containing trimethylchlorosilane) for derivatization reaction (this step is rapid, because the derivatization reagent decomposes with water ), the reaction temperature was 70°C, and the derivatization was performed for 2h.

[0057] The gas phase column and program used in this experiment are as follows:

[0058] Column: Sh-Rxi-5sil-MS column (30*0.25*0.25)

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com