Zinc-polymer aqueous rechargeable battery with three-chamber structure and preparation method thereof

A technology of rechargeable batteries and polymers, which is applied in the field of zinc-polymer water-based rechargeable batteries and its preparation, can solve the problems of limited application potential, easy volatilization of organic solvents, and increased internal resistance of batteries, and achieve low cost and solution Non-volatile, freezing point lowering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] A preparation method of a zinc-polymer aqueous rechargeable battery with a three-chamber structure, comprising the following steps:

[0052] S1: Preparation of polymer positive electrode:

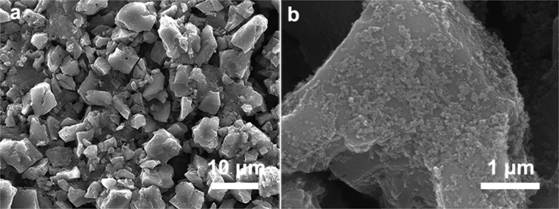

[0053] S1-1: Activate the conductive carbon fiber cloth in 2 M nitric acid solution, then wash it with deionized water until neutral, dry it at 60°C and use it as a current collector;

[0054] S1-2: Disperse porous activated carbon with high specific surface area, conductive carbon black, and polyvinylidene fluoride in N-methylpyrrolidone according to the mass ratio of 7:2:1, stir, and mix uniformly to obtain a carbon powder slurry;

[0055] S1-3: Apply the carbon powder slurry obtained in step S1-2 evenly on the carbon fiber cloth treated in step S1-1, then place it in a vacuum oven at 120°C, and dry it for 12 hours to obtain an activated carbon substrate;

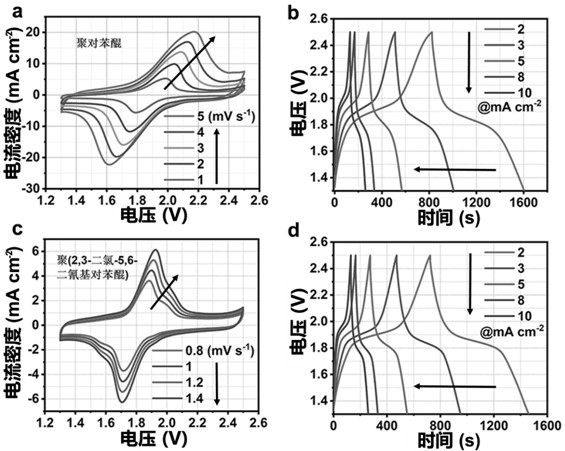

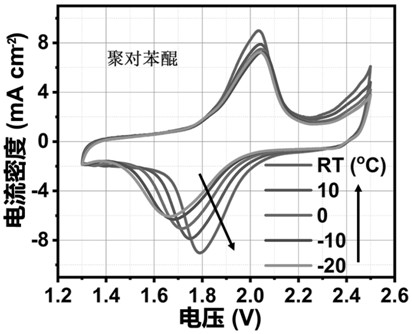

[0056] S1-4: Dissolve any one of 1,4-benzoquinone, 2,3-dichloro-5,6-dicyano-p-benzoquinone, and 2,5-dihydroxy-1,4-benzoquinon...

Embodiment 1

[0069] S1: Preparation of poly-p-benzoquinone positive electrode:

[0070] S1-1: Put the highly conductive carbon fiber cloth into 2 M dilute nitric acid for 4 hours of activation treatment, then wash it repeatedly with deionized water until it becomes neutral, and dry it in a vacuum oven at 60°C for 12 hours before use .

[0071] S1-2: High specific surface area porous activated carbon powder (2230 g / cm 2 ), conductive carbon black, and polyvinylidene fluoride were dispersed in the N-methylpyrrolidone solution according to the mass ratio of 7:2:1, and then magnetically stirred until a uniformly mixed carbon powder slurry was obtained.

[0072] S1-3: Coat the carbon powder slurry evenly on the activated carbon cloth in step S1-1, and adjust the carbon powder loading range from 2 to 11 mg / cm by controlling the coating amount of the slurry 2 , and then dried in a vacuum oven at 120°C for 12 hours to obtain an activated carbon substrate; the substrate load can be adjusted by th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com