Preparation method of compound premixed flour

A technology of ready-mix flour and buckwheat flour, which is applied in the direction of dough preparation, dough processing, pre-baked dough processing, etc. It can solve the problem of lowering blood fat and cholesterol, not meeting nutritional and functional requirements, and not having auxiliary hypoglycemic properties, etc. problem, to achieve the effect of softening blood vessel aging, avoiding spoilage bacteria or pathogenic bacteria pollution, mellow taste and aftertaste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

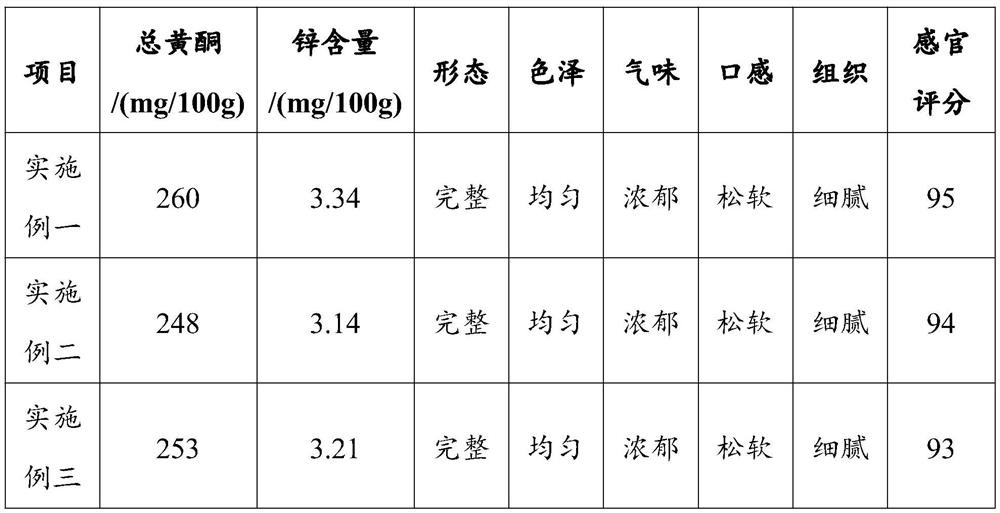

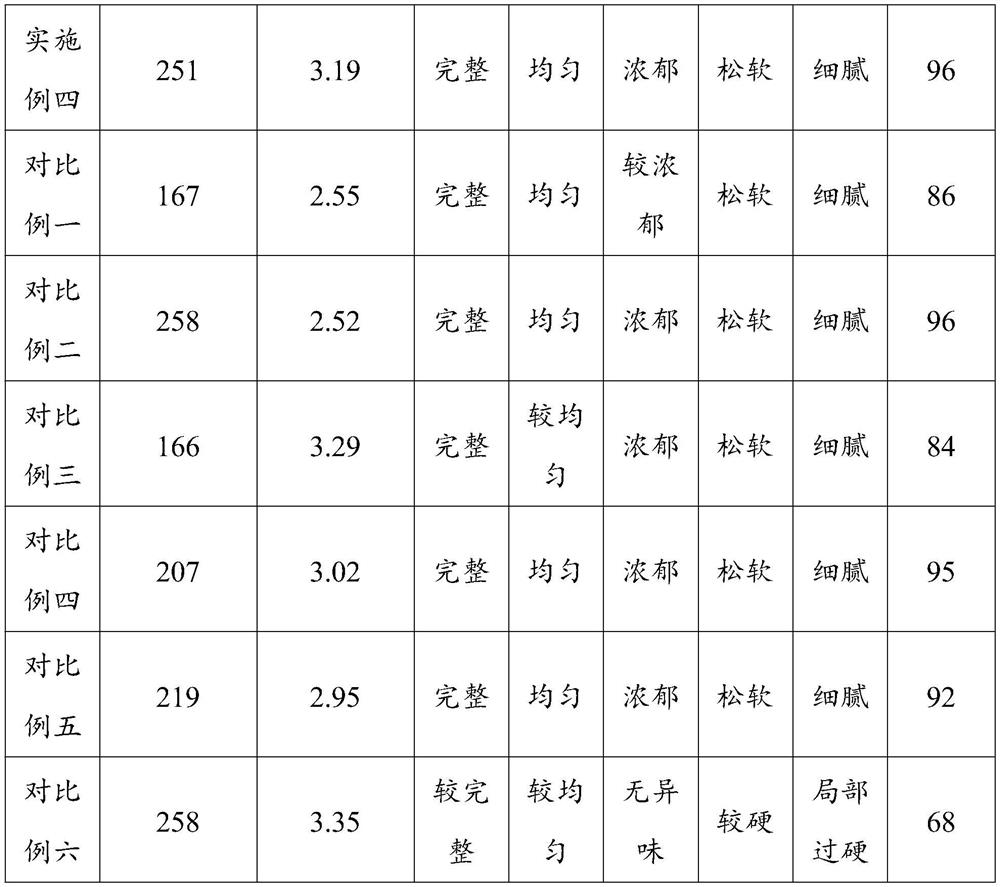

Examples

preparation example Construction

[0032] The preparation method of the compound ready-mixed powder of the present embodiment, comprises the steps:

[0033] Step 1: Wash 1-1.5 parts by weight of Rhizoma Polygonatum, 1-1.5 parts by weight of Dangshen, and 8-12 parts by weight of pumpkin seed shells, and then crush them. After sieving through a 60-80 mesh screen, boil water at 90-100°C Boil for 10 minutes, add drinking water to cool to 45-55°C and keep warm, add 4-7 parts by weight of compound enzyme at a stirring speed of 100r / min and adjust the pH to 5.5-6.0 with slightly acidic electrolyzed water, then adjust the power It is 300-320W, 580-680nm light wavelength assisted extraction, the extraction time is 100-120min, and finally after centrifugation at 10000r / min for 5-10min, the filtrate is collected to obtain the natural extract.

[0034]Step 2: Stir 10-15 parts by weight of the natural extract at a speed of 3000-4000 r / min, and then add 5-10 parts by weight of honey, 0.5-1.0 parts by weight of salt, 5-15 par...

Embodiment 1

[0048] The preparation method of compound ready-mix powder in the present embodiment, comprises the steps:

[0049] Step 1: Wash 1.5 parts by weight of Rhizoma Polygonatum, 1.5 parts by weight of Dangshen and 12 parts by weight of pumpkin seed husks, and then crush them. After sieving through a 60-80 mesh screen, boil them in boiling water at 90-100°C for 10 minutes, add to drinking Cool the water to 45-55°C and keep it warm. At 100r / min stirring speed, add 7 parts by weight of compound enzyme and adjust the pH to 5.5-6.0 with slightly acidic electrolyzed water, then adjust the power to 300-320W, 580-680nm The light wavelength assists the extraction, the extraction time is 100-120min, and finally after centrifugation at 10000r / min for 5-10min, the filtrate is collected to obtain the natural extract.

[0050] Step 2: Stir 15 parts by weight of the natural extract at a speed of 3000-4000r / min and add 10 parts by weight of honey, 1.0 parts by weight of salt, 15 parts by weight of...

Embodiment 2

[0054] The preparation method of compound ready-mix powder in the present embodiment, comprises the steps:

[0055] Step 1: Wash 1 part by weight of Polygonatum, 1 part by weight of Dangshen and 8 parts by weight of pumpkin seed shells, and then crush them, pass through a 60-80 mesh screen, boil in boiling water at 90-100°C for 10 minutes, add to drinking Cool the water to 45-55°C and keep it warm. At 100r / min stirring speed, add 4 parts by weight of compound enzyme and adjust the pH to 5.5-6.0 with slightly acidic electrolyzed water, then adjust the power to 300-320W, 580-680nm The light wavelength assists the extraction, the extraction time is 100-120min, and finally after centrifugation at 10000r / min for 5-10min, the filtrate is collected to obtain the natural extract.

[0056] Step 2: Stir 10 parts by weight of the natural extract at a speed of 3000-4000r / min and add 5 parts by weight of honey, 0.5 parts by weight of salt, 5 parts by weight of egg white liquid, 3 parts by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com