Biogas preparation device and method

A preparation device and biogas technology, applied in biochemical equipment and methods, biochemical cleaning devices, enzymology/microbiology devices, etc., can solve the problems of high equipment performance requirements, low efficiency, high temperature and high pressure, etc., to reduce production costs , Improve preparation efficiency and save energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

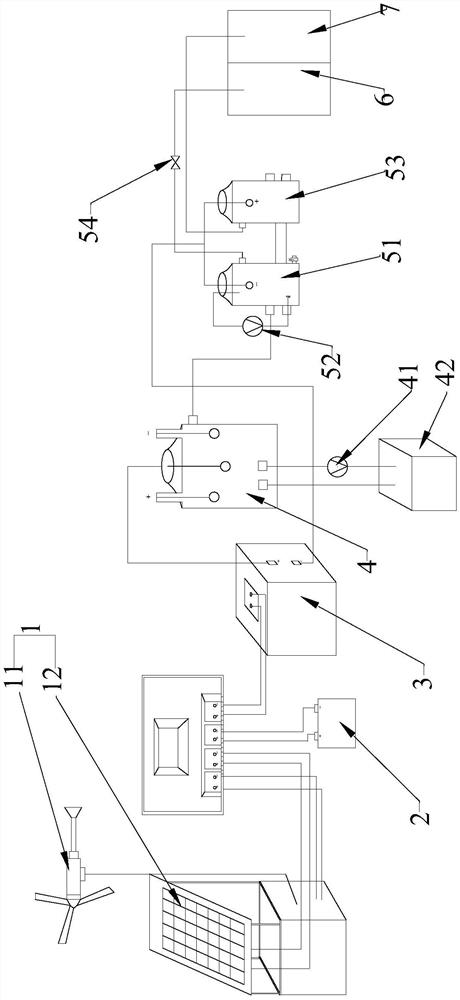

[0037] like figure 1As shown, a biogas preparation device comprising a venting power generating system 1 for microbial electrolysis and dark fermentation producing biogas, a double chamber methane pure chamber for purification of fermentation in the reaction chamber 4, The scenery generating system 1 includes a fan 11 for wind power generation, a photovoltaic assembly 12 for solar power generation, a light-emitting power generating system 1 for powering the electrical components in the reaction chamber 4 and a double chamber methane purified chamber, biogas preparation device Including a battery 2 for storing excess electrical energy generated by the scenery generating system 1, when the electric energy generated by the scenery power generation system 1 is not enough, the battery 2 is supplemented to the reaction chamber 4 and the electric component in the double chamber methane purified chamber. The cathode electrode and the anode electrode are provided inside, and the reaction c...

Embodiment 2

[0051] A sludge is obtained from a pig farm biogas in Zhejiang Province, and the separation of anaerobic sludge is finally obtained by mixing bacteria for methane.

[0052] A 1000 mL triangular bottle was taken for 30 min in a high pressure steam sterilization pot at 100 ° C. After cooled to room temperature, 300 ml of anaerobic sludge was added to the triangular bottle and stored in an environment without other fungi. Formulated liquid medium, ingredient of liquid medium: 10 g / L ammonia acetic acid, 2g / L protein, 2g / L yeast powder, 0.5 g / L cysteine, 0.4g / l K 2 HPO 4 , 0.2g / L MGCL 2 · 6h 2 O and 1L distilled water, the formulated liquid medium was sterilized under 121 ° C for 15 min, and 600 ml of liquid medium was added to 1000 ml of sterilized triangular bottle.

[0053] The above-mentioned 300 ml of anaerobic sludge was added to 600 ml of liquid medium and mixed, and the mixed uniform triangular bottle was allowed to stand for 7 days in anaerobic case, and the anaer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com