High-thermal-stability, high-fatigue-resistance, narrow-half-width and multistable optical tunable laser material

A technology with high thermal stability and fatigue resistance, applied in lasers, nonlinear optics, laser components, etc., can solve problems that affect spectral bandwidth and laser coherence, laser spectral line distortion, and laser can not be effectively stabilized, etc., to achieve excellent The effects of thermal stability, large range of light-induced changes, and large helical torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

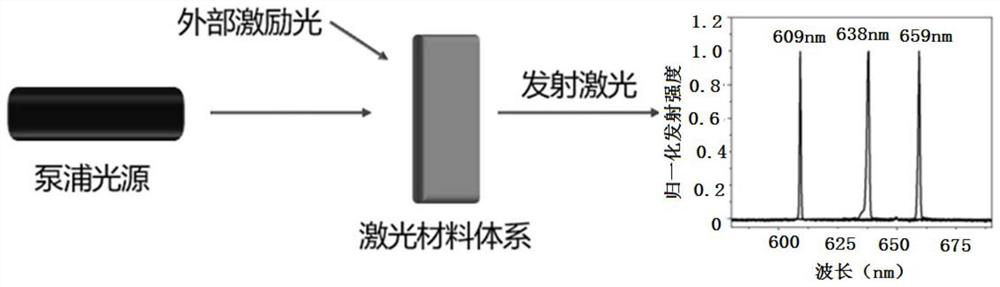

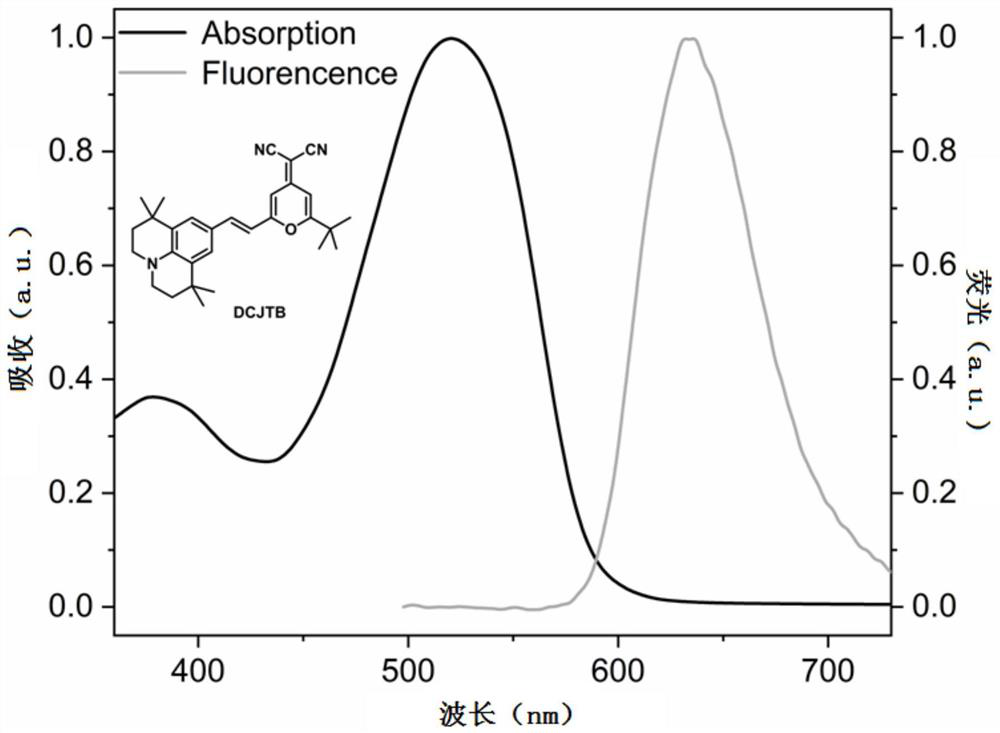

[0042] Preparation of an optically tunable laser material with high thermal stability, strong fatigue resistance, narrow half-width, and multi-stable state: Mix 2.0mg compound 1o, 0.5mg gain medium DCJTB and 38.0mg commercial common nematic liquid crystal E7 , to obtain optically tunable laser materials with high thermal stability, strong fatigue resistance, narrow half-width, and multi-stable states.

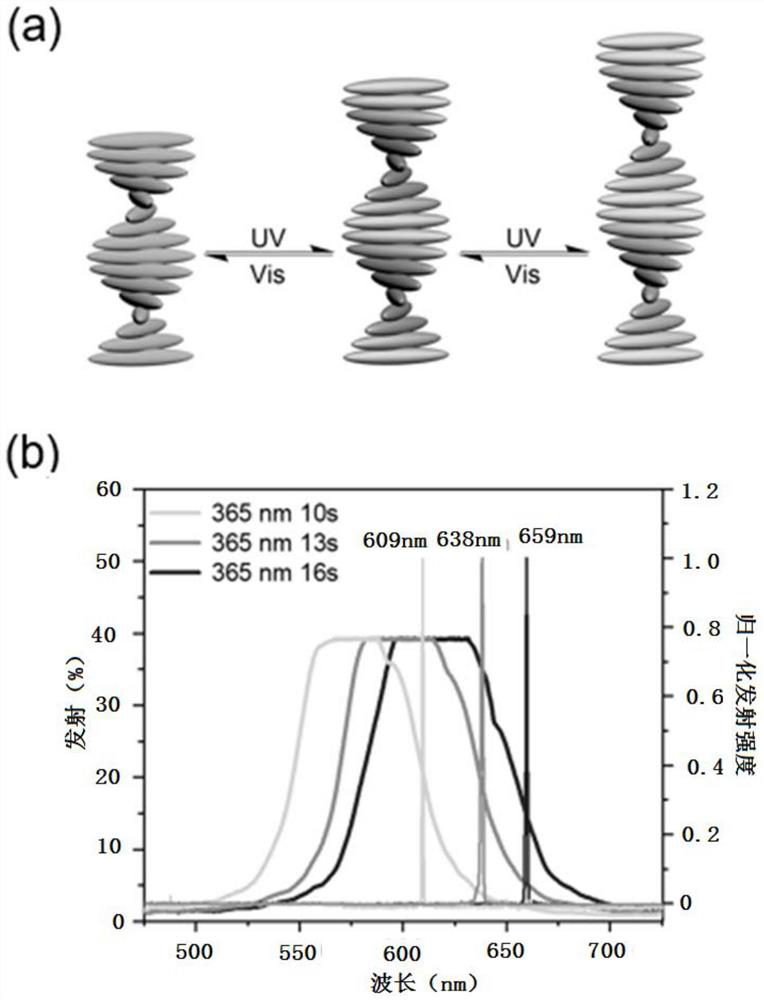

[0043] Optically tunable laser description: The above-mentioned optically tunable laser material with high thermal stability, strong fatigue resistance, narrow half-width, and multi-stable state is packaged in a liquid crystal cell with a size of 15.13*21mm and a cell thickness of 5 microns. figure 2 It is a schematic diagram of the emission spectrum and the corresponding Bragg emission band of the optically tunable laser material in Embodiment 1 of the present invention. figure 2 In a, when the external excitation light uses ultraviolet light (365nm), the power is 4mW cm -2...

Embodiment 2

[0045] Preparation of an optically tunable laser material with high thermal stability, strong fatigue resistance, narrow half-width, and multi-stable state: Mix 2.0mg compound 1o, 0.5mg gain medium DCJTB and 38.0mg commercial common nematic liquid crystal E7 , to obtain optically tunable laser materials with high thermal stability, strong fatigue resistance, narrow half-width, and multi-stable states.

[0046] Optically tunable laser description: The above-mentioned optically tunable laser material with high thermal stability, strong fatigue resistance, narrow half-width, and multi-stable state is packaged in a liquid crystal cell with a size of 15.13*21mm and a cell thickness of 5 microns. When the external excitation light uses ultraviolet light (365nm), the power is 2mW·cm -2 When the liquid crystal cell is irradiated, the pitch of the liquid crystal system increases with the change of different irradiation times. According to the Bragg equation, the Bragg reflection wavele...

Embodiment 3

[0048] Preparation of an optically tunable laser material with high thermal stability, strong fatigue resistance, narrow half-width, and multi-stable state: Mix 2.0mg compound 1o, 0.5mg gain medium DCJTB and 38.0mg commercial common nematic liquid crystal E7 , to obtain optically tunable laser materials with high thermal stability, strong fatigue resistance, narrow half-width, and multi-stable states.

[0049] Optically tunable laser description: The above-mentioned optically tunable laser material with high thermal stability, strong fatigue resistance, narrow half-width, and multi-stable state is packaged in a liquid crystal cell with a size of 15.13*21mm and a cell thickness of 5 microns. When the external excitation light uses visible light (405nm), the power is 4mW·cm -2 When the liquid crystal cell is irradiated, the pitch of the liquid crystal system increases with the change of different irradiation times. According to the Bragg equation, the Bragg reflection wavelength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com