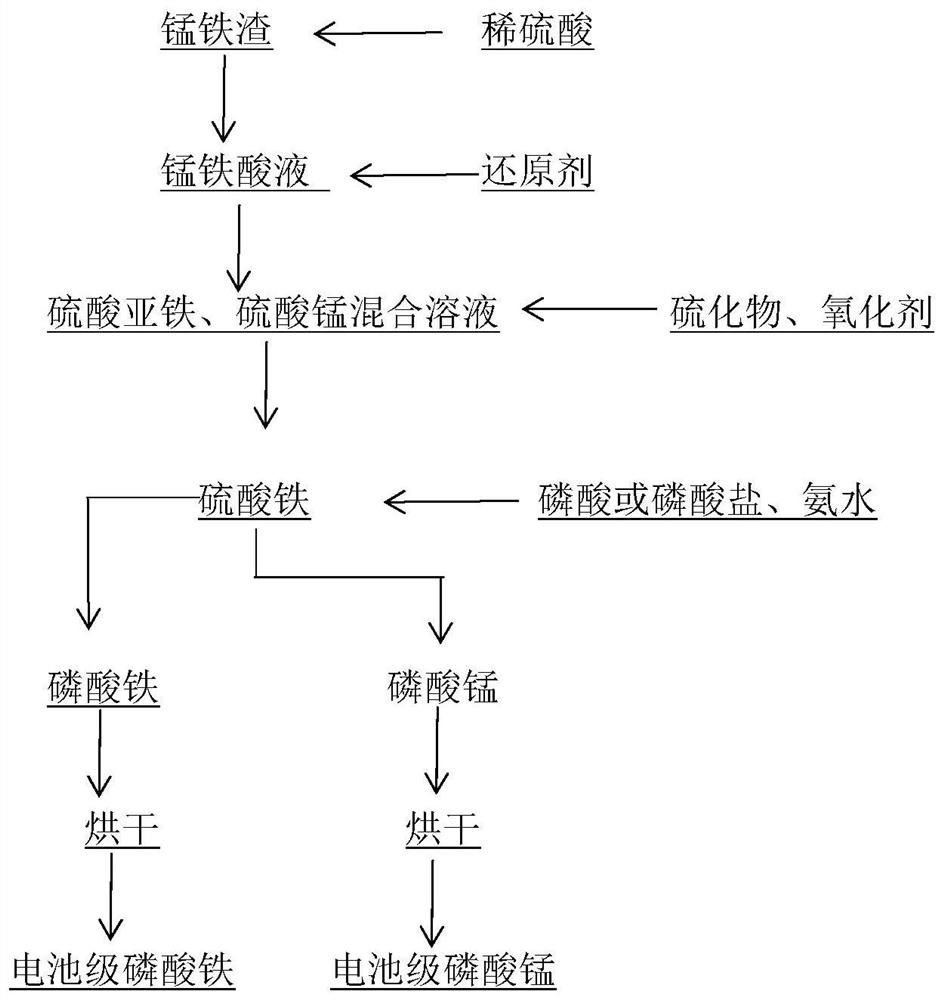

Method for preparing battery-grade iron phosphate and manganese phosphate from manganese ore leaching residues

A technology for extracting slag and iron phosphate, which is applied in the direction of iron sulfate, chemical instruments and methods, phosphorus compounds, etc., can solve the problems of insufficient utilization and recycling, pollute the environment, waste of resources, etc., and achieve increased production costs, improved purity, The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take 100g of manganese ore leaching slag from a certain factory, including manganese: 10.85%, iron: 22.34%, add 200ml of dilute sulfuric acid with a mass fraction of 50%, and stir for 3 hours at 50°C. Solid-liquid separation was obtained to obtain ferromanganese acid solution, and 10 g of reduced iron powder was added to obtain a mixed solution of ferrous sulfate and manganese sulfate. Under the condition of 60° C., 1.5 ml of ammonium sulfide solution and 20 ml of hydrogen peroxide were added, stirred and reacted for 1 hour, and solid-liquid separation was performed to obtain a purified solution. According to iron: phosphorus = 1:1.5, 5 g of ammonium dihydrogen phosphate was added, and at 80° C., the pH was adjusted to 2.5 with ammonia water, and the reaction was stirred for 3 hours. Filtrate to obtain iron phosphate precipitation, continue to adjust the pH of the filtrate to 5.5 to obtain manganese phosphate. The obtained iron phosphate is dried at 250°C for 1 hour an...

Embodiment 2

[0030] Take 1500g of manganese ore leaching slag from a certain factory, including manganese: 1.85%, iron: 17.13%, add 2500ml of dilute sulfuric acid with a mass fraction of 40%, and stir for 1 hour at 80°C. Solid-liquid separation was carried out to obtain ferromanganese acid solution, and 192 g of reduced iron powder was added to obtain a mixed solution of ferrous sulfate and manganese sulfate. Under the condition of 50° C., 20 ml of sodium sulfide solution and 100 ml of hydrogen peroxide were added, stirred and reacted for 2 hours, and solid-liquid separation was performed to obtain a purified solution. According to iron: phosphorus = 1:1.3, add 200 g of diammonium hydrogen phosphate, adjust the pH to 3 with ammonia water at 75° C., and stir for 2 hours. Filtrate to obtain iron phosphate precipitation, continue to adjust the pH of the filtrate to 5 to obtain a small amount of manganese phosphate. The obtained iron phosphate is dried at 200°C for 2 hours and then dried at 5...

Embodiment 3

[0032] Take 200g of manganese ore leaching slag from a certain factory, including manganese: 5.54%, iron: 10.22%, add 250ml of dilute sulfuric acid with a mass fraction of 80%, and stir at 70°C for 1h. Solid-liquid separation was obtained to obtain ferromanganese acid solution, and 11 g of reduced iron powder was added to obtain a mixed solution of ferrous sulfate and manganese sulfate. Under the condition of 60° C., 2 ml of sodium sulfide solution and 5 ml of hydrogen peroxide were added, stirred and reacted for 1 hour, and solid-liquid separation was performed to obtain a purified solution. According to iron: phosphorus = 1:1.5, add 10 g of ammonium dihydrogen phosphate, and adjust the pH to 6 with ammonia water under the condition of 80° C. to obtain mixed precipitation of iron phosphate and manganese phosphate. Dry the obtained mixed precipitate at 600°C for 3 hours to obtain battery grade ferromanganese phosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com