A functional double network hydrogel and its application

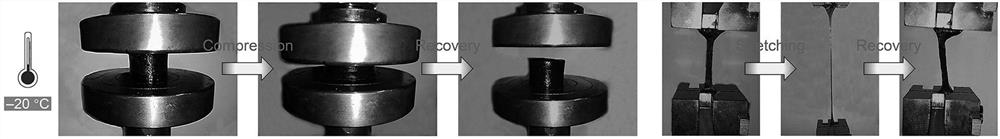

A hydrogel and double network technology, applied in the field of materials science, can solve the problems of limited application range of flexible wearable technology, loss of stretchability and original elasticity, freezing of hydrogel, etc., to achieve improved recoverability and The effect of mechanical properties, maintaining low temperature drug effect, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

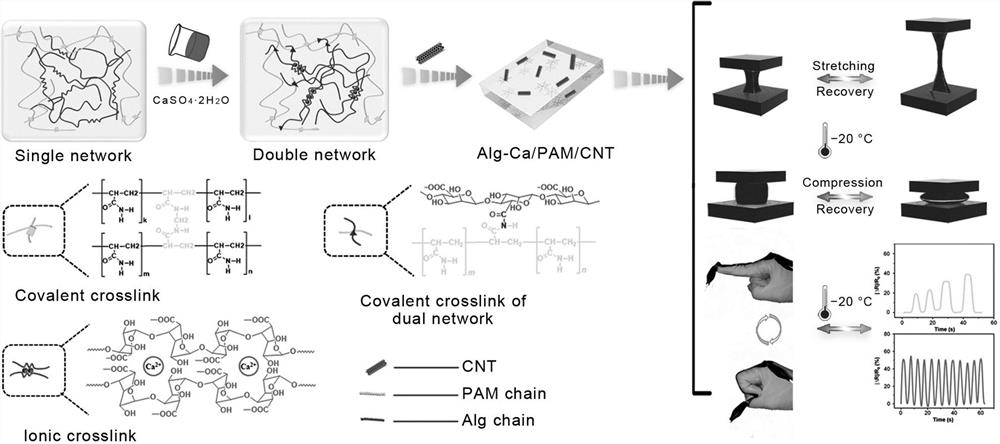

[0032] The preparation method of the functionalized double network hydrogel of the present invention comprises the following steps:

[0033] (1) First add distilled water to two mixed powders of sodium alginate (Alg) and acrylamide (AM) to form an aqueous solution, then fully stir the solution until all the powders are dissolved to obtain solution S1;

[0034] (2) dissolving carboxylated carbon nanotube powder in solution S1, and ultrasonically dispersing in a water bath to obtain solution S2 containing carboxylated carbon nanotubes;

[0035] (3) Add N,N'-methylenebisacrylamide (MBA), tetramethylethylenediamine (TEMED), ammonium persulfate (APS) and calcium sulfate dihydrate (CaSO 4 2H 2 O) in the stirring solution S2, fully stir and mix to obtain the pre-polymerization solution S3 completely;

[0036] (4) Quickly transfer the pre-polymerization solution S3 to a glass mold, place the sealed mold under ultraviolet light, and complete the polymerization by ultraviolet light to...

Embodiment 1

[0044] (1) First add distilled water to Alg (0.01 g / mL) and AM (0.14 g / mL) mixed powders to form an aqueous solution, then stir the solution thoroughly until all the powders are dissolved to obtain solution S1;

[0045] (2) Dissolve carboxylated carbon nanotube powder (0.20 mg / mL) in solution S1, and ultrasonically disperse in a water bath to obtain solution S2 containing carboxylated carbon nanotubes;

[0046] (3) Add MBA (0.05 mg / mL), TEMED (0.10 mg / mL), APS (1.50 mg / mL) and CaSO in sequence 4 2H 2 O (13.00 mg / mL) in the stirring solution S2, the stirring time is 1 h, and the mixing is complete to obtain the pre-polymerization solution S3;

[0047] (4) Quickly transfer the pre-polymerization solution S3 into a glass mold, place the sealed mold under ultraviolet light for 1 h, and place the sample at room temperature for 3 h to complete the polymerization, and complete the polymerization by ultraviolet light to obtain ion-covalent double crosslinking Alg-Ca / PAM / CNT function...

Embodiment 2

[0049] (1) First add distilled water to Alg (0.02 g / mL) and AM (0.15 g / mL) mixed powders to form an aqueous solution, then stir the solution thoroughly until all the powders are dissolved to obtain solution S1;

[0050] (2) Dissolve carboxylated carbon nanotube powder (0.30 mg / mL) in solution S1, and ultrasonically disperse in a water bath to obtain solution S2 containing carboxylated carbon nanotubes;

[0051] (3) Add MBA (0.06 mg / mL), TEMED (0.20 mg / mL), APS (1.60 mg / mL) and CaSO in sequence 4 2H 2 O (14.00 mg / mL) in the stirring solution S2, the stirring time is 2h, and the mixing is complete to obtain the pre-polymerization solution S3;

[0052] (4) The pre-polymerization solution S3 was quickly transferred to the glass mold, and the sealed mold was placed under ultraviolet light for 2 hours, and the sample was placed at room temperature for 4 hours to complete the polymerization, and the polymerization was completed by ultraviolet light to obtain ion-covalent double cros...

PUM

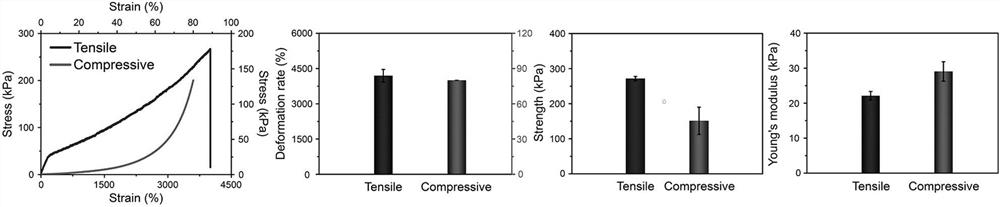

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com